Splicing Tapes for Melamine Impregnated Papers

Elevating efficiency during paper processing for melamine faced board production

Elevating efficiency during paper processing for melamine faced board production

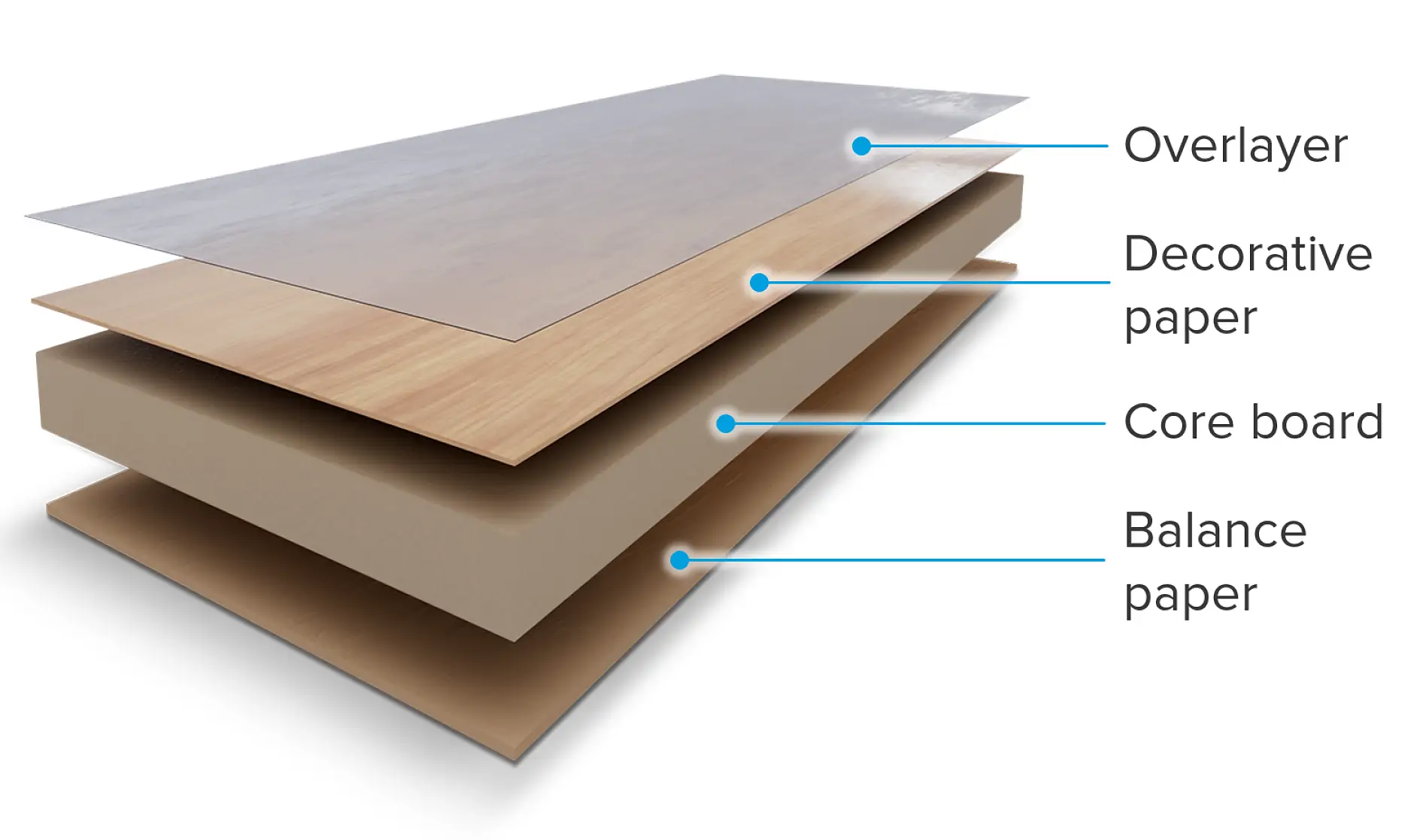

Melamine faced board layers

Decorative melamine faced boards are used in the furniture and flooring industry. They are made up of wood based panels covered by layers of paper material.

In case of laminate flooring this would typically be an overlay/wear layer, a decorative layer, and a balance paper layer. Depending on the layer and application, these papers are printed and impregnated with melamine resin.

While being processed through the impregnation line, papers - and applied splicing tapes - need to resist moisture and temperature.

Today, the demands that face splicing solutions are more challenging than ever: Different paper qualities, higher speeds, and the focus to increase output call for a new splicing tape generation.

Please watch our video for a full benefit overview of our splicing tape tesa® 54951.

With our specially developed splicing tapes, we are able to tick all the boxes for maximized process efficiency:

| tesa® 54951 | tesa® 51951 | tesa® 54242 |

|---|---|---|

| For easy and fast application: applied in one straight line, integrated segmented design |

For manual tape application: applied in several individual stripes of tape |

Split labels |

Carefully remove the liner in the direction of the splitting labels. Ready to splice!

Reel preparation: Ensure a straight paper edge for easy application.

Apply splitting labels in suitable distance over entire reel width.

To avoid damage to the web, trim the paper’s edges on both sides.

Apply the tape in a straight line, leave a gap of about one thumb’s width to the edge of the roll.

Apply pressure to ensure excellent adhesion between tape and paper (best use a squeegee).

tesa® 54951 melamine splicing

| Adhesive | Liner | Thickness [µm / mil] | Color | Temperature resistance | Tack | Shelf life | Transport and storage |

|---|---|---|---|---|---|---|---|

| Repulpable acrylic | Paper | 105 / 4 | Blue | 220 °C / 430 °F | High | 12 months | In original packaging at 15-30 °C (59-86 °F), 40-75% RH |