Electronic Adhesive Solutions: The Future of Consumer Electronics

As innovations in the electronics industry continue to expand at lightning speed, the production of electronic components poses even more challenges for manufacturers. Applications and devices often require unique adhesive solutions with parts becoming smaller and more complex, while product quality and performance must be maintained.

We at tesa® have made it our mission to develop cutting-edge adhesives for electronic components providing multiple applications, such as bonding, mounting, sealing, cushioning, shielding, and encapsulation. Our advanced electronic adhesive solutions allow for precise application at high production rates and reliable performance.

Choose from a wide range of specially developed electronic adhesive tapes for a variety of devices that will meet your specific demands. We have successfully evolved with the electronics industry over the past 30 years and our proximity to our customers enables us to anticipate future trends in product design. As a leading global supplier of adhesive solutions for the electronics industry, tesa® is proud to say: We shape today’s field of electronic technologies and enable tomorrow’s developments.

Devices and Typical Applications of Electronic Adhesives

With our sophisticated technological expertise related to tape application in electronic devices, we can help you choose the adhesive tape that fits your needs best. We co-develop with leading OEMs and component manufacturers of the industry. Take a look at our innovative tape solutions, optimize the production processes of your devices and benefit from more design freedom:

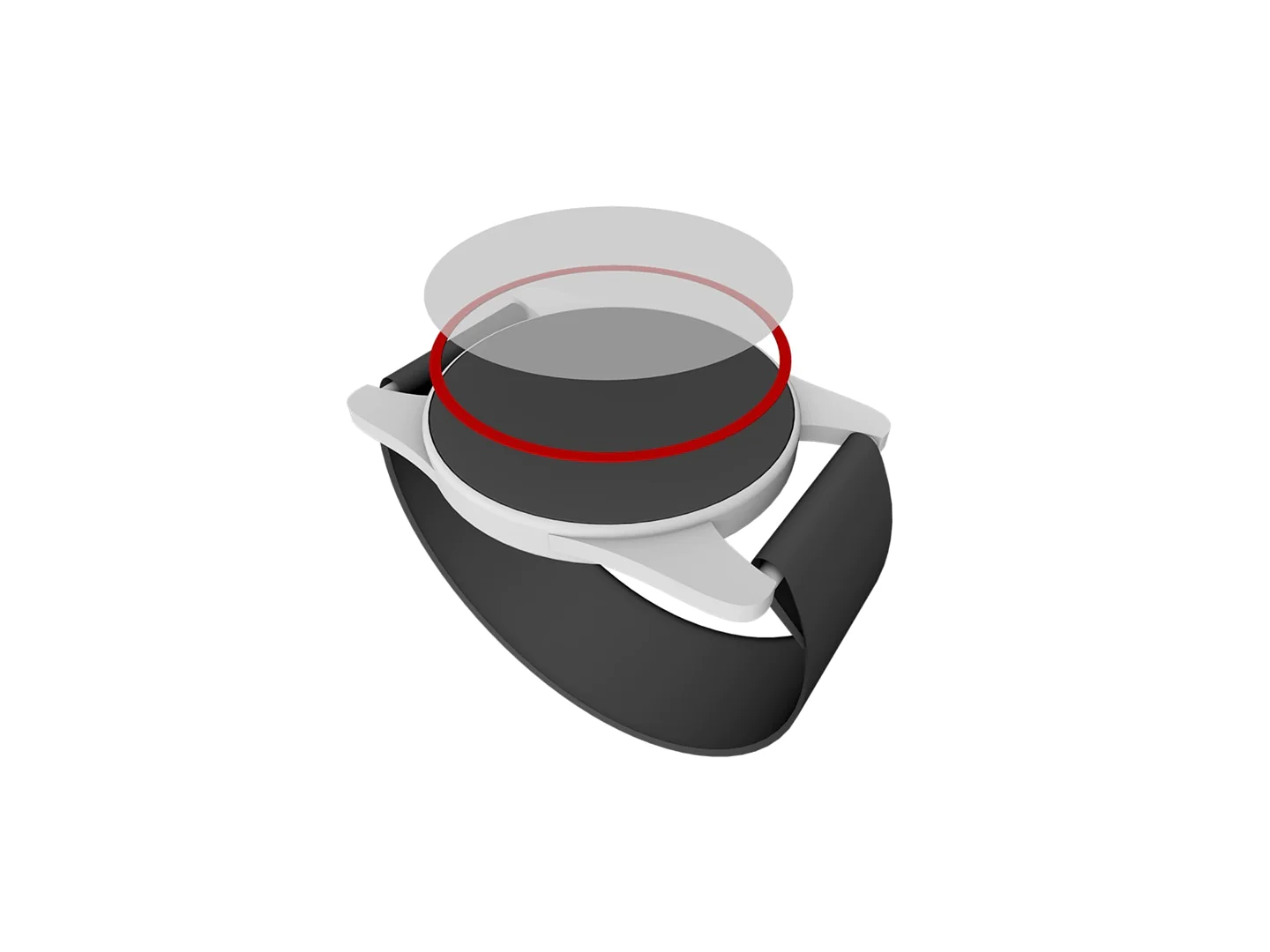

Smartphones, tablets, displays, OLED technologies, notebooks, TVs and monitors, wearables, accessories, smart home.

Our broad range of adhesive tapes for electronic applications provides your devices with maximum performance, modern design, and high functionality.

Electronic adhesive for device components

Key Features of Our Electronic Adhesives

We understand the key factors needed for adhesive tape to offer you the ideal performance.

Whether you need double-sided adhesive tape or conductive adhesive for electronics: We have you covered. Our products ensure top bonding, protection, and longevity as well as the ability to withstand even the harshest environmental conditions such as vibration, moisture, and temperature fluctuations. At the same time, we actively contribute to sustainability through our products. By making it possible to easily remove the individual components of a smartphone, we improve its recyclability and aim to extend the life of your electronic equipment in general. When it comes to thematerials of our electronic adhesives, a key concern for us is the use of more environmentally and climate friendly, recycled and organic raw materials while maintaining the same level of quality.

The most significant tapes in our product range can be classified into the categories of mounting solutions, functional solutions, and display lamination solutions. Each tape assortment combines different features needed to fulfill specific functionsfor your electronic applications. These features include, among others:

- Bonding performance

- Impact resistance

- Residue-free removal

- Anti-repulsion

- LSE performance

- Reliability

- Chemical resistance

- Conformability

- Electrical conductivity

- Thermal management

- Moisture blocking

- Outgassing resistance

Electronic Adhesives: Our Product Range

As electronic adhesive materials and features vary, it can be challenging to figure out which adhesive will work on your specific electronics.

With our reliable solutions and exceptional service, we support you during the entire product development process to find the best tape solution for your individual requirements. Our global key account management teams offer outstanding cross-border, around the clock support. On top of that, our technical experts provide support on location to assist at your manufacturing site.