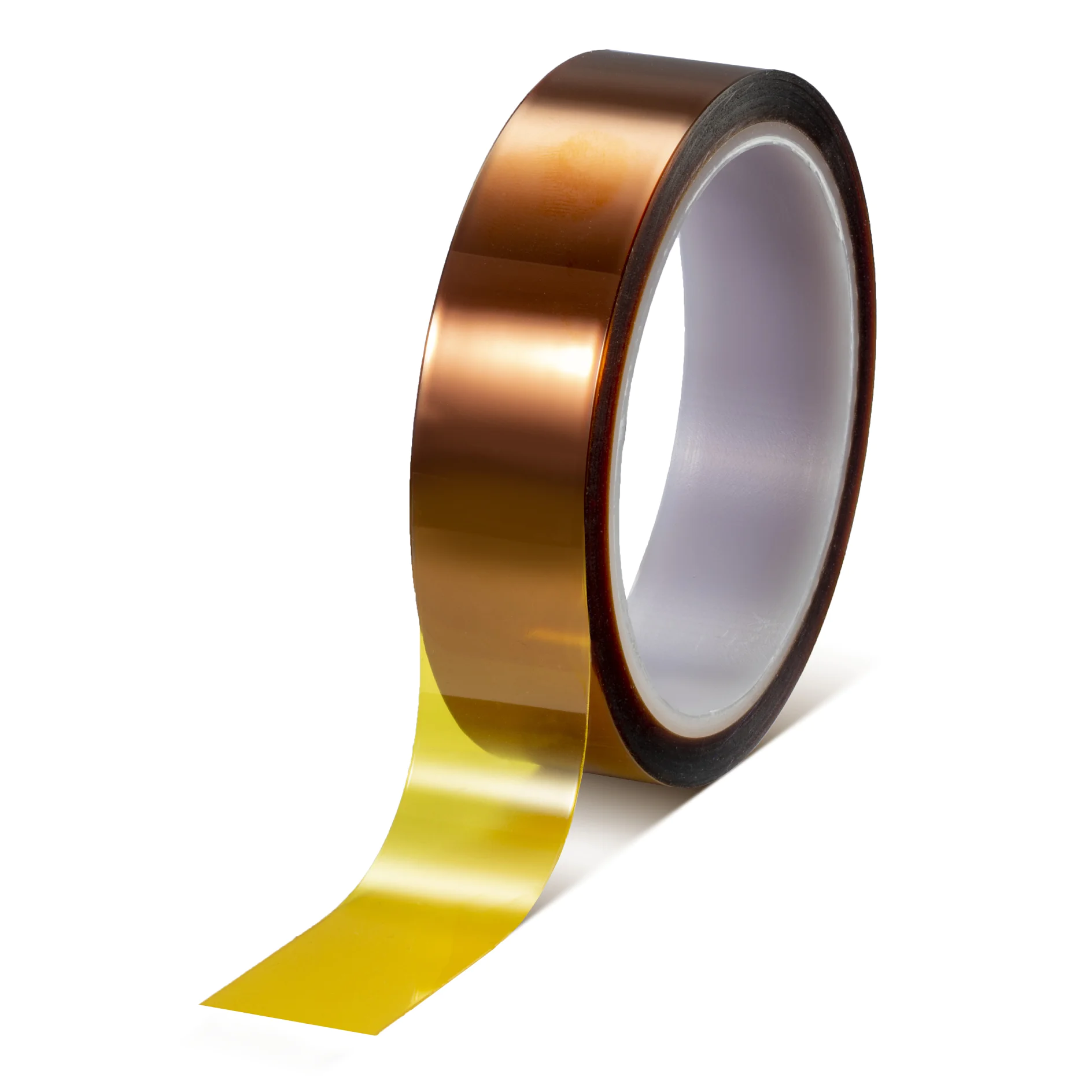

We offer a wide range of masking tapes for industrial sectors, including automotive, transport, metalworking, and furniture production. Our high-temperature masking tapes are ideal for powder coating, printed circuit board manufacturing, and other heat-sensitive processes, providing clean removal, chemical resistance, and reliable surface protection.

The right tape depends on your sector, the coating or paint used, and curing conditions. Our range includes different backings such as paper, cloth, or filmic, and adhesives, including silicone for high-temperature masking, designed for clean removal without leaving residues or damaging the surface. For tasks like sandblasting, tapes resistant to abrasion under high pressure with strong backings are vital for reliable surface protection.