Tape Technology

for Converters

Evolving solutions for ever-changing needs

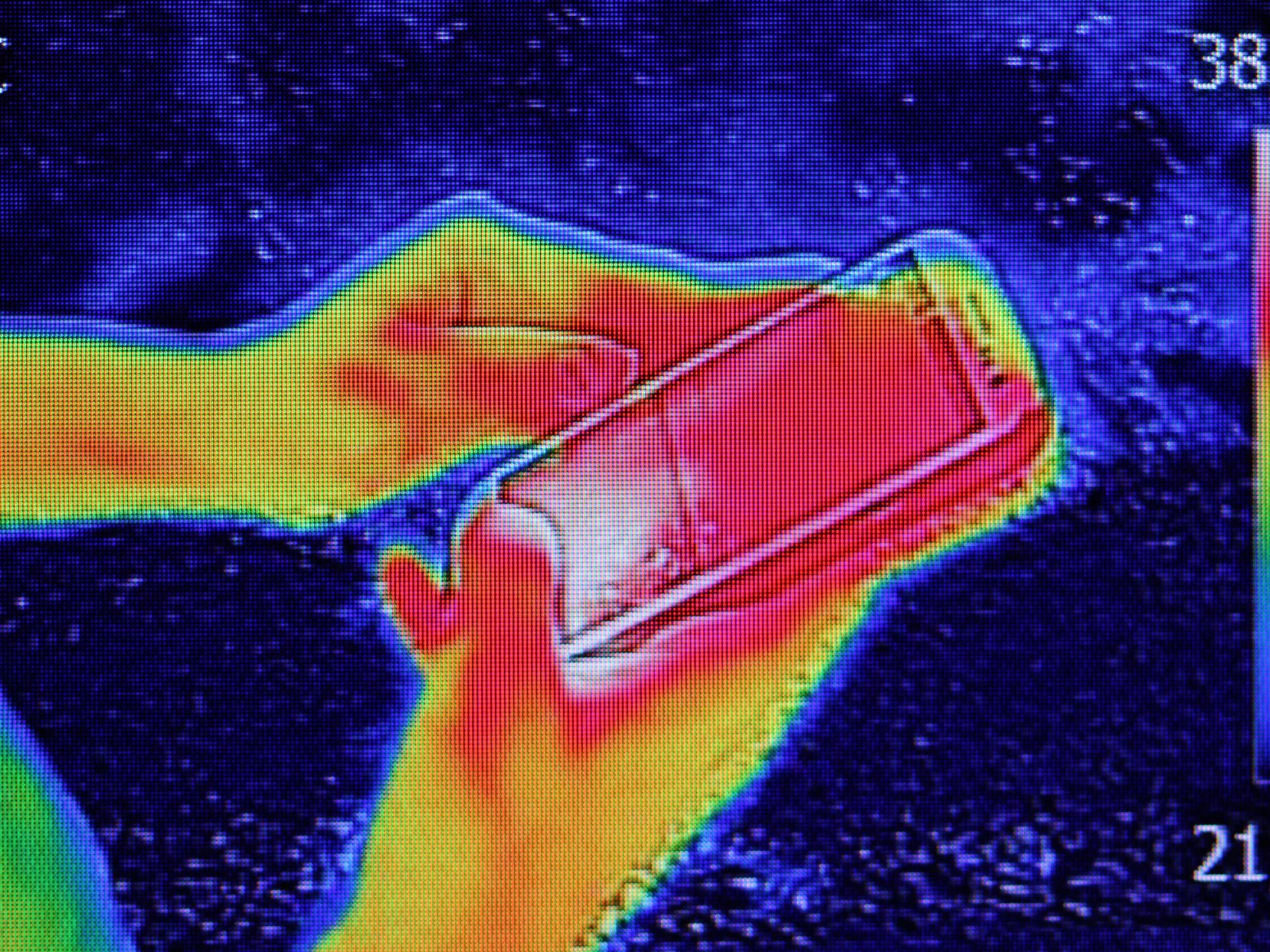

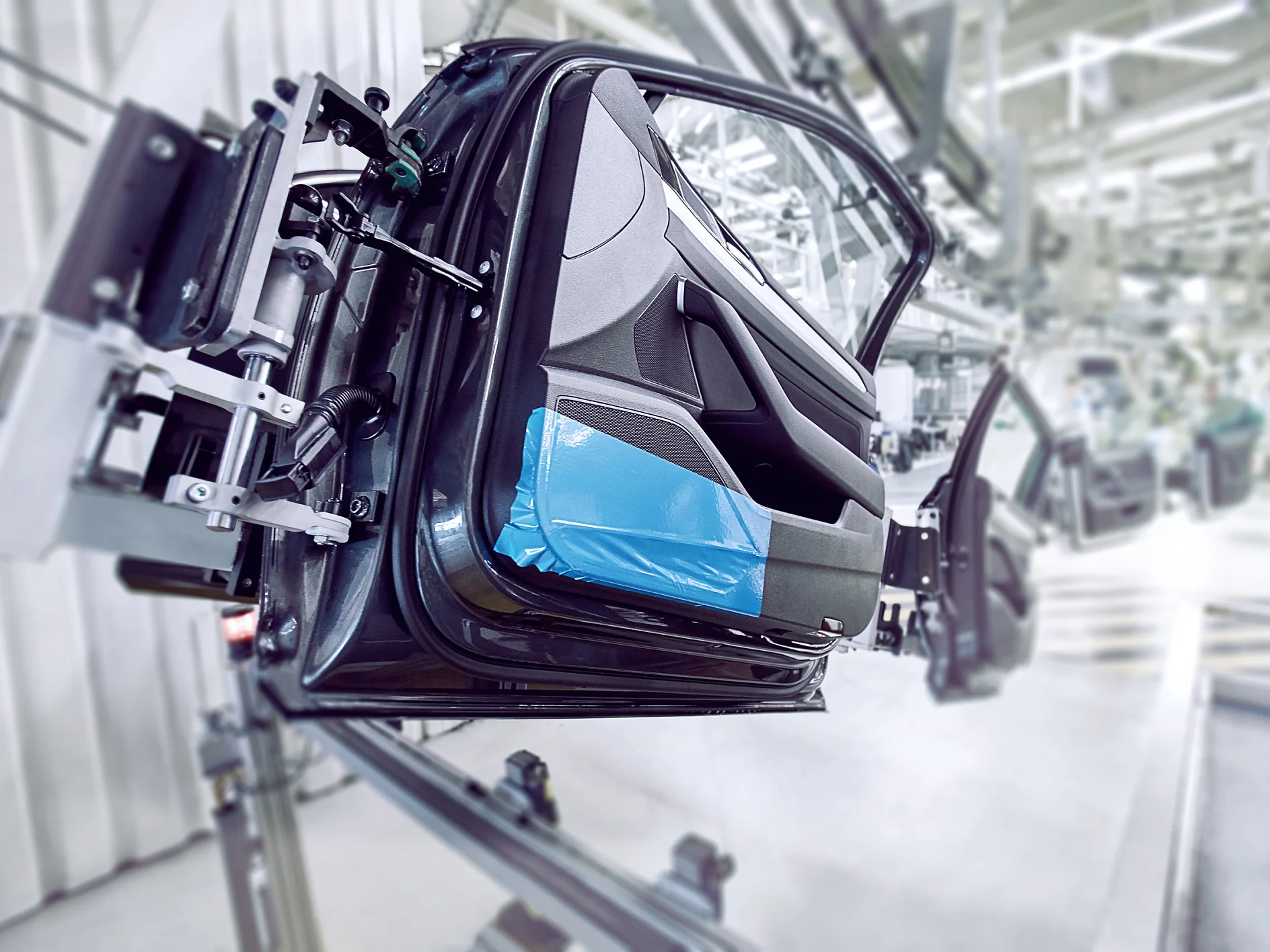

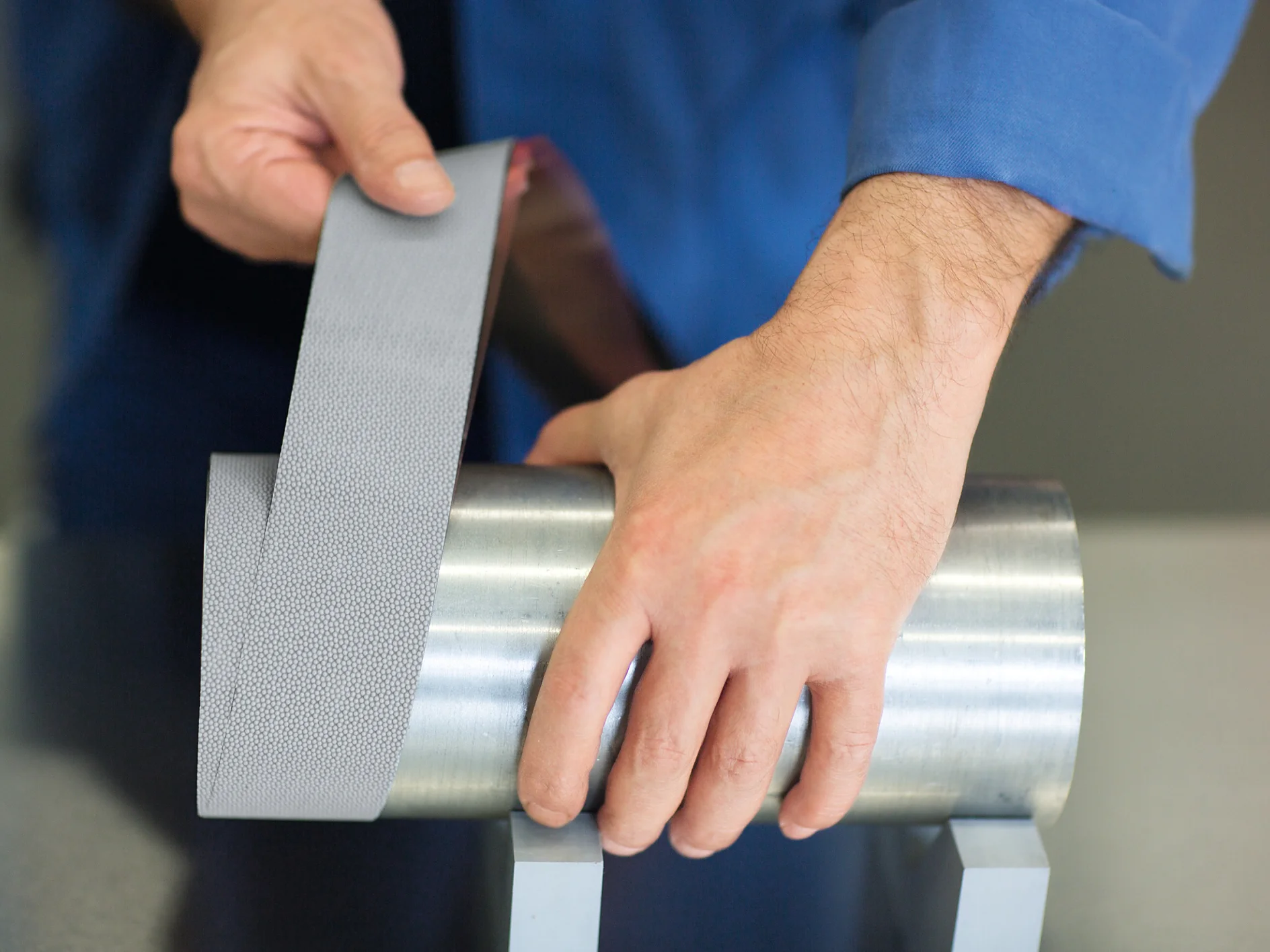

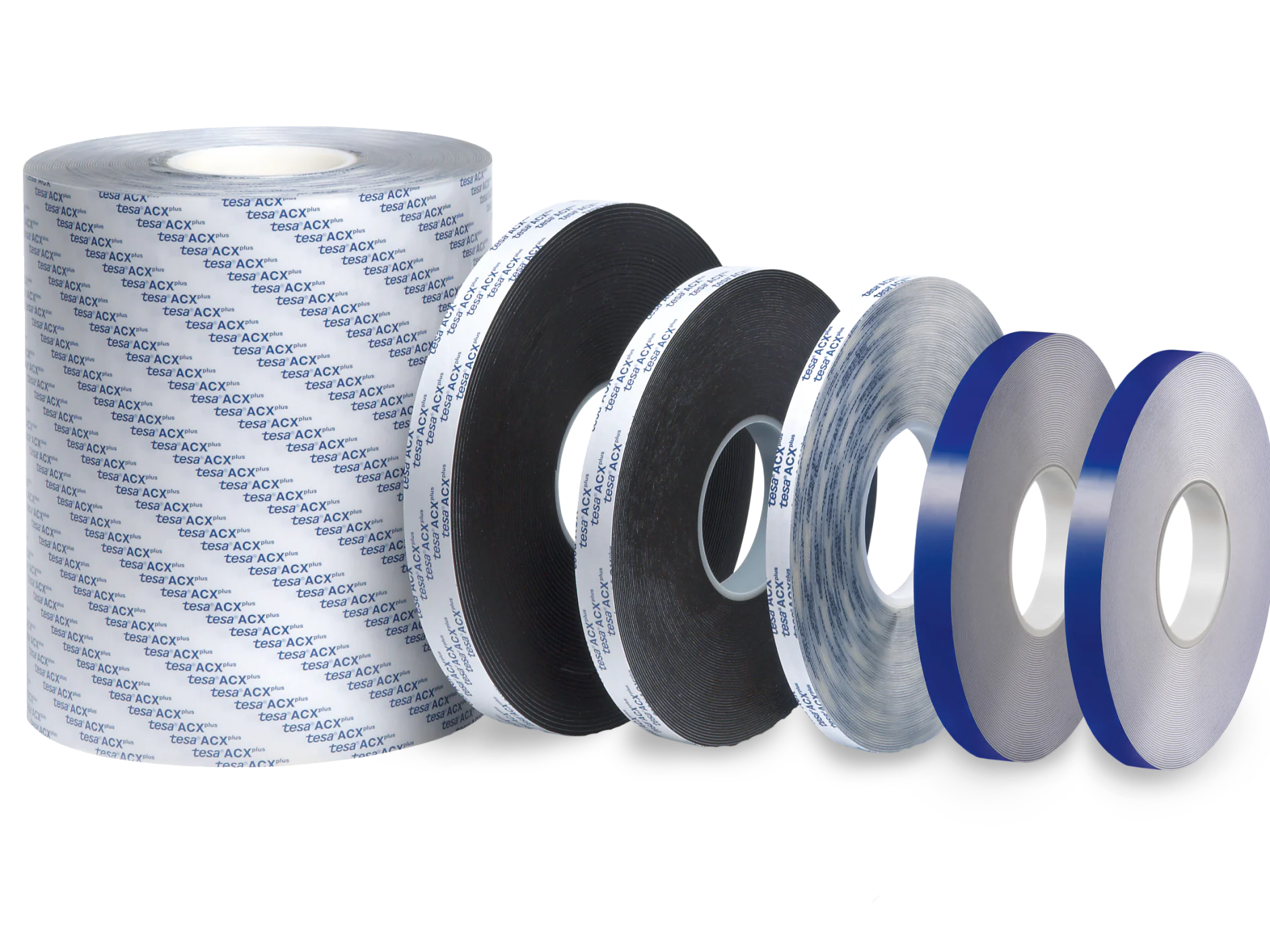

As products and manufacturing processes evolve, tape converting plays an increasingly critical role in generating efficiencies and enabling new design opportunities. That is why we make sure our Converters get access to tape solutions that do not compromise on quality and have been developed for a multitude of industrial applications including bonding, lamination, masking, surface protection, repairing, hole covering, etc.

Discover our Top Converter Picks, on which you will benefit from improved ordering, sampling speed, and flexibility!

Core assortment brochures for Converters

Proven technologies for endless applications

Die-cut design inspiration