Powering

innovation

together

Innovation is in tesa’s DNA and is one of our core strengths. Our forward-thinking adhesive solutions can help you deliver an EV battery with reduced weight and optimized space – so you can innovate too. Let’s work together to discover the solution for your application while increasing efficiency in production.

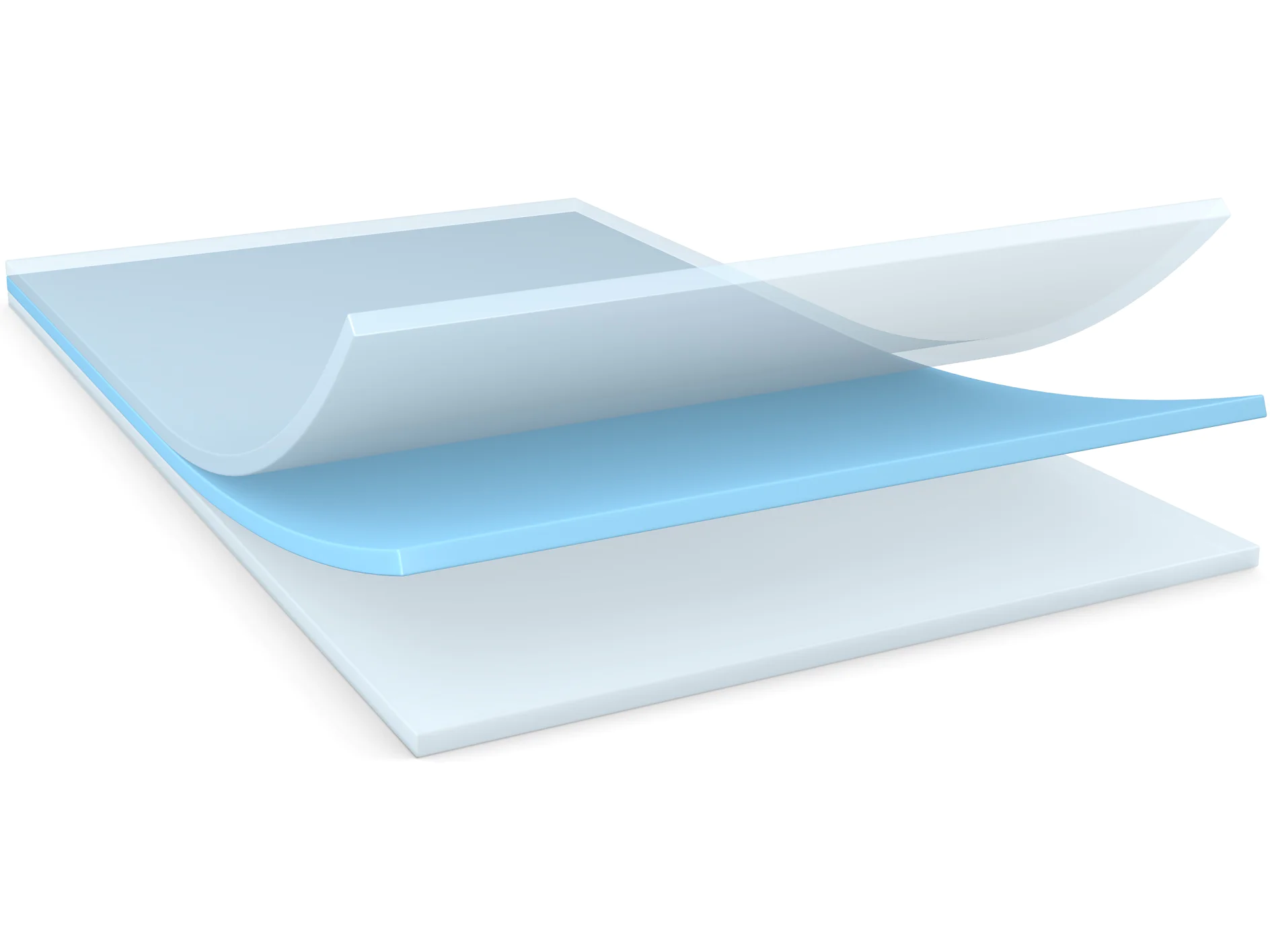

UV epoxy

Our cutting-edge UV epoxy tape enables structural bonding of cells with reliable electric insulation performance.

The tape also displays high performance in damp-heat resistance and elasticity tests. EV batteries stay protected against dielectric breakdown, while providing for a cell-to-pack configuration that structurally weaker adhesives would not allow.

Furthermore, its product design facilitates flexible production processes, allowing UV-activation before and after application of the tape.

UV coating

Cells can be insulated with a spray coating process, cured by UV light. Pre-treatment of the cell must be carried out to guarantee the adhesion of the coating. In end-of-line testing, measurement of coating thickness, particularly at the radius, presents a great challenge. The cells must be left to finish drying before they can be moved – another issue which potentially holds up the production process. With the use of our UV epoxy solution, these challenges do not arise.

Cell wrapping for EV batteries

Only one curing iteration is required for UV epoxy cell wrapping. Compared to UV coating, cell wrapping quality control is simpler – particularly for cell housings with radial deviations. This is because the backing thickness is constant, always providing secure electrical insulation. If reworking should be required, tape removal from around the cells is much easier compared to coating.