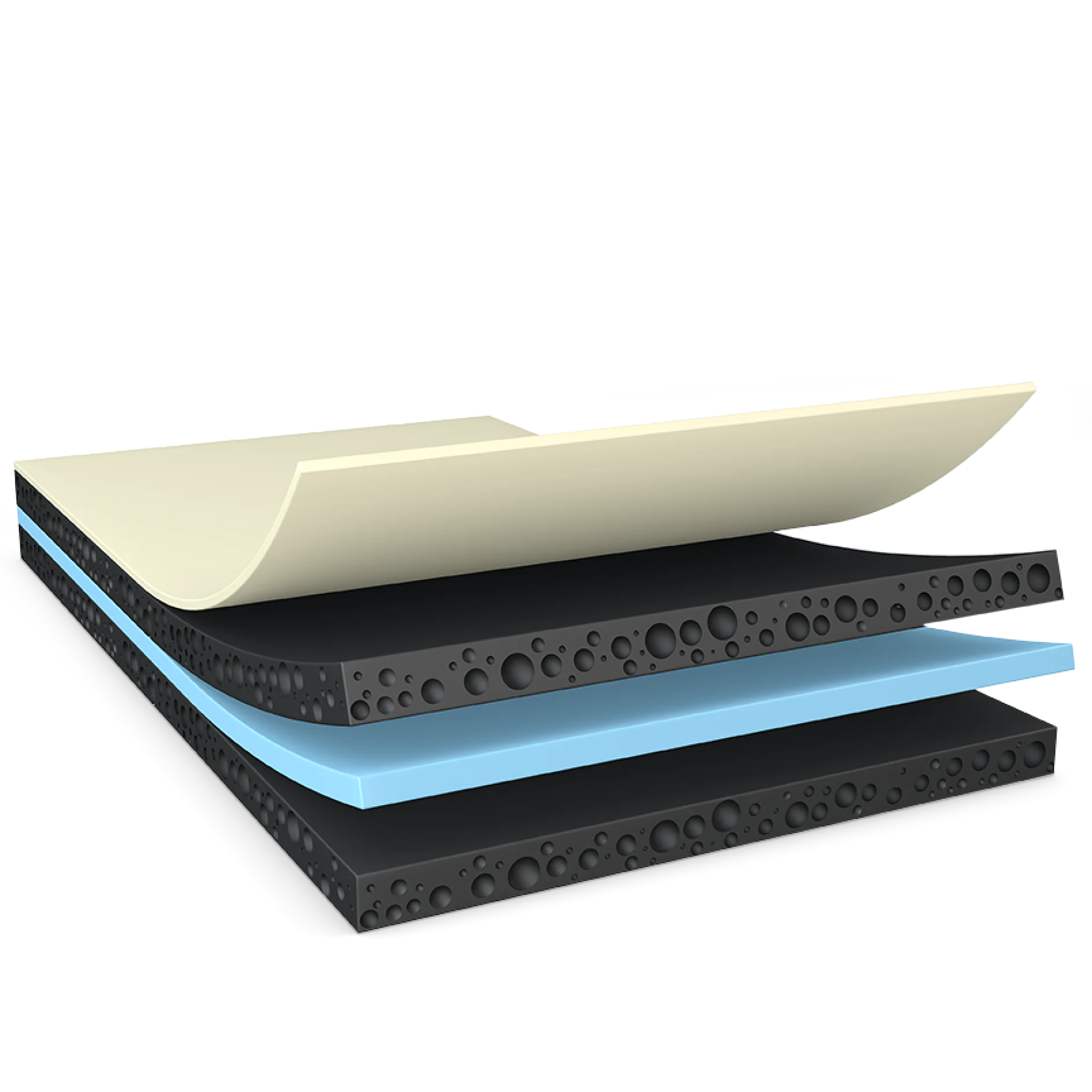

- Elastic and viscous characteristics provide the strength for a permanent bond

- Constant product features over time even in outdoor conditions

- Acrylic foam tapes can compensate static loads over the entire bond's duration of the product life cycle

Acrylic foam tapes for strong bonding solutions

Acrylic foam tapes with strong performance

Bonding components or substrates can be very challenging. Our acrylic foam tape assortment has been developed over the years to meet the extreme demands of industrial applications. Today, our acrylic foam tapes’ strong bonding capabilities are relied upon by manufacturers worldwide.

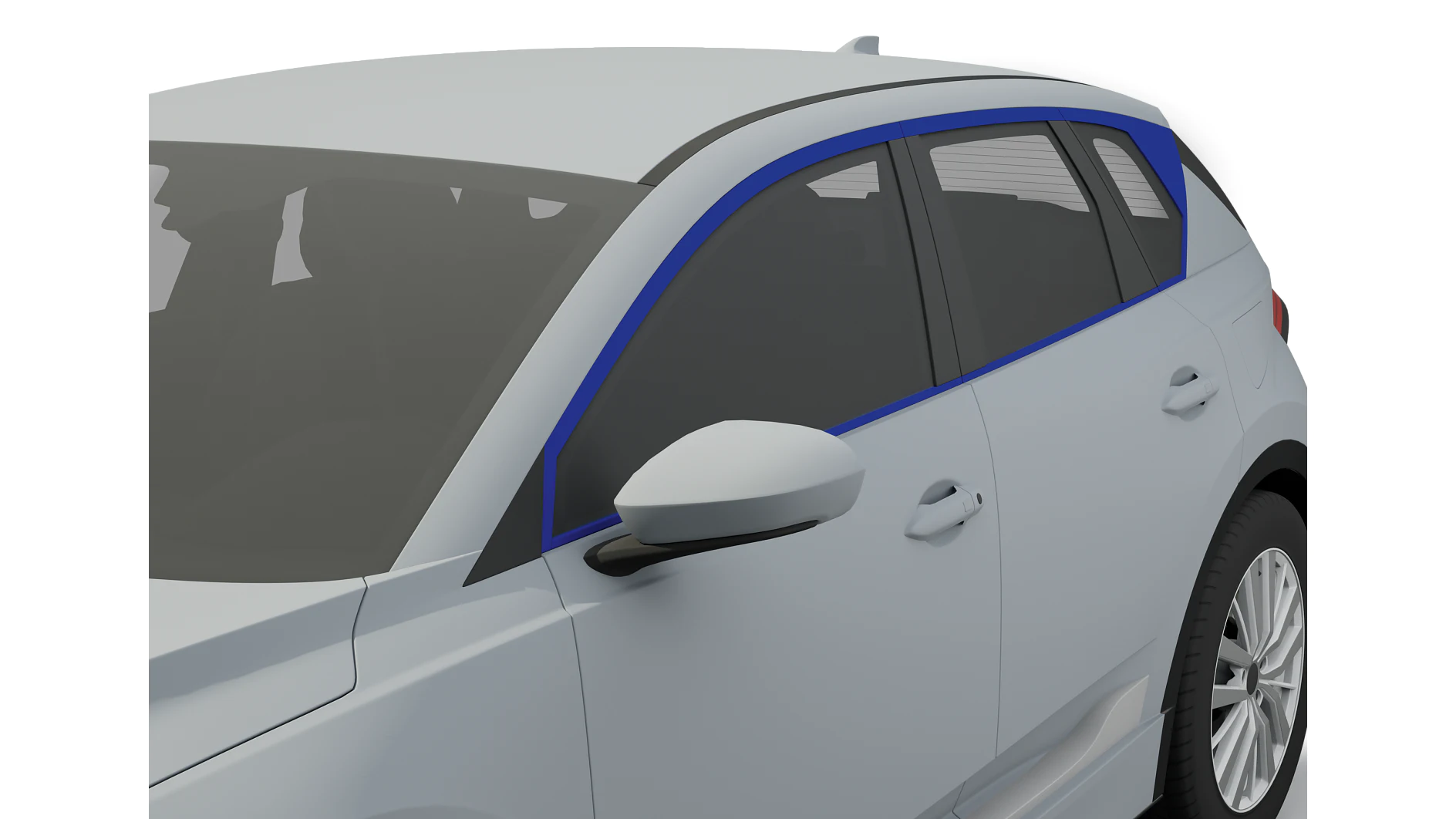

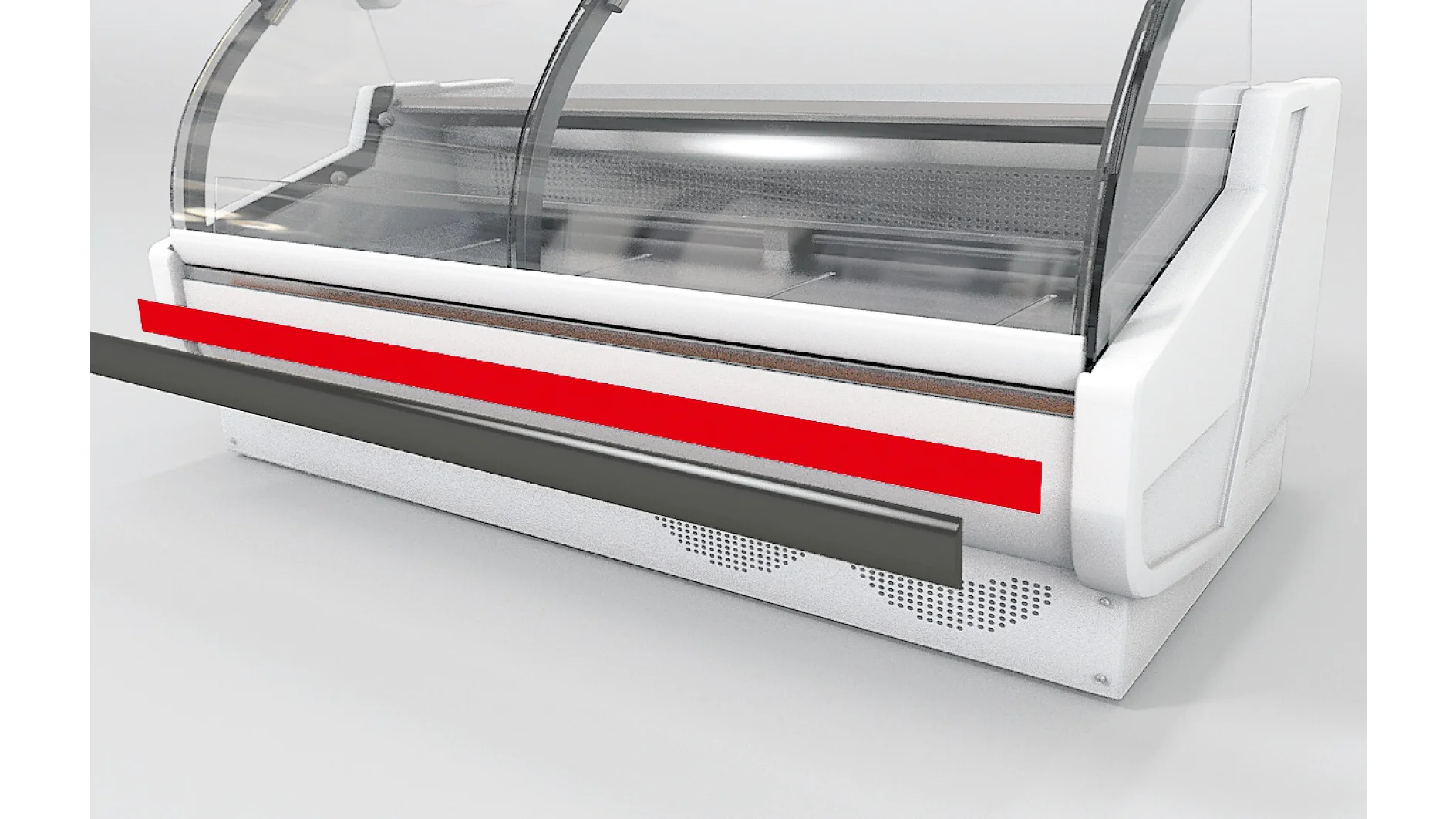

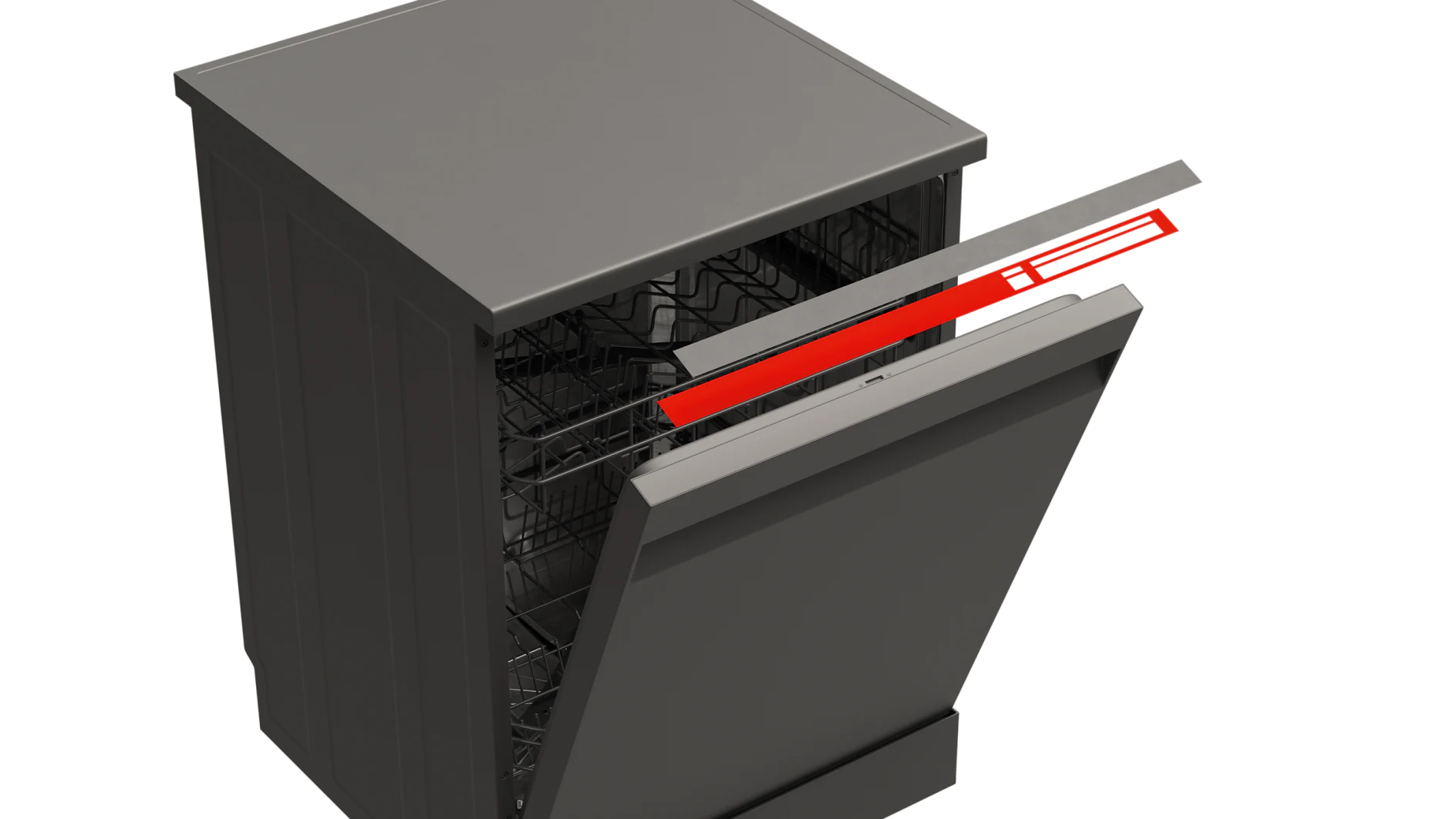

Acrylic foam tapes are widely used in many different industries including the automotive, building components, appliances, and electronics sectors. In manufacturing, acrylic foam tapes can replace mechanical fasteners and liquid adhesives. As there is no need to drill into material or use screws, nuts, or bolts, faster assembly time can be realized, potentially at a lower cost and without damaging the materials used. Overall, acrylic foam tapes offer greater design flexibility and, with no raised fastener heads, improved aesthetics.

Exemplary applications in various industries

Key features of our acrylic foam tape series

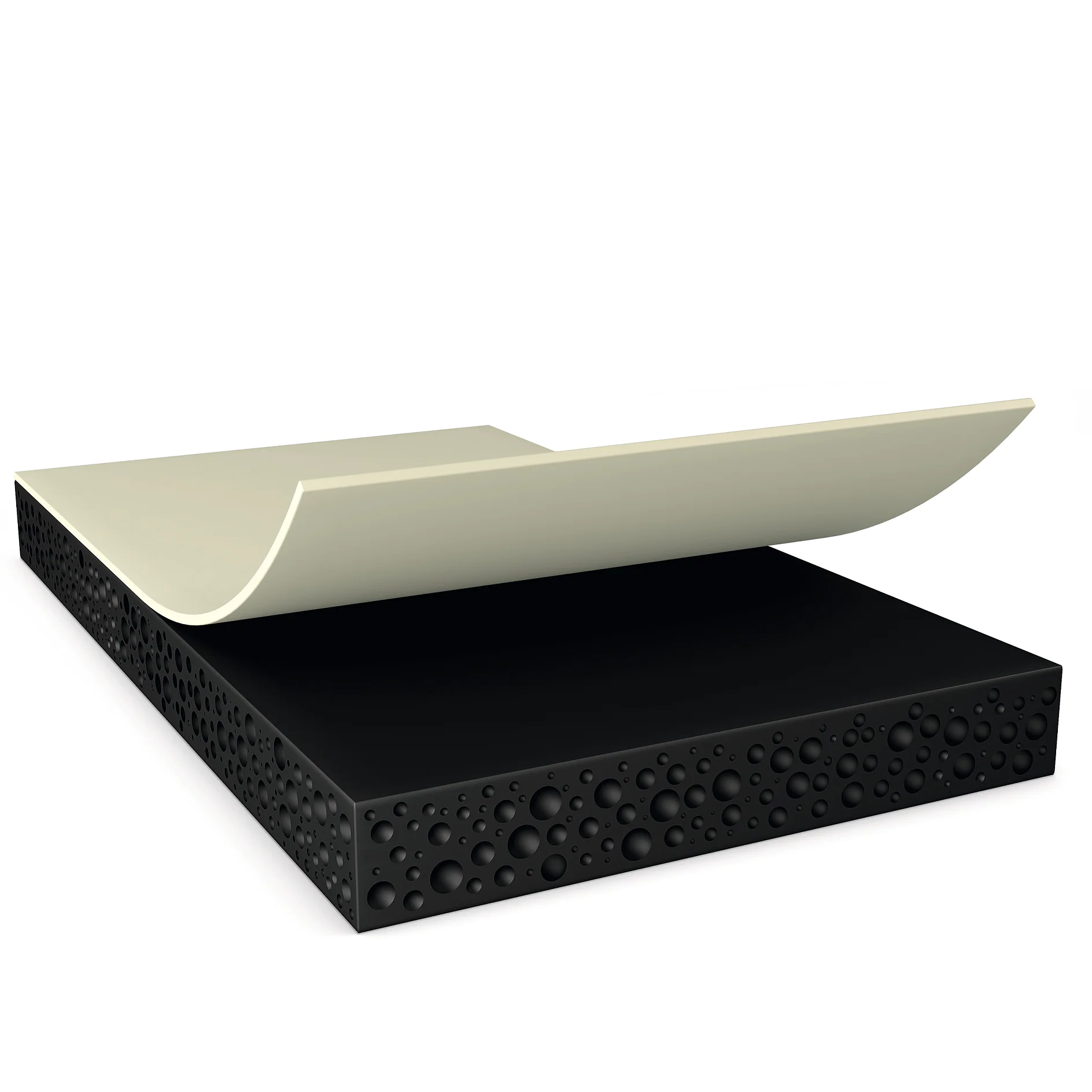

To achieve their strong bonding performance, our acrylic foam tapes rely on our own innovative technologies and special acrylic adhesive systems. The high performance of our acrylic foam tapes is based on a special feature: viscoelasticity.

Viscoelasticity describes a material performance which is defined by both elastic and viscous characteristics. The elastic restoring forces provide inner strength while the viscous part of the material behavior leads to relaxation of mechanical stresses. tesa® ACXplus employs a special acrylic adhesive system that combines both effects in an outstanding way.

Inner core strength

Stress dissipation

- Our acrylic foam tapes compensate for thermal elongation of different materials

- Dynamic stresses are optimally dissipated for a secure bond

Together with the viscoelastic nature of acrylic foams, the tapes provide several advantages:

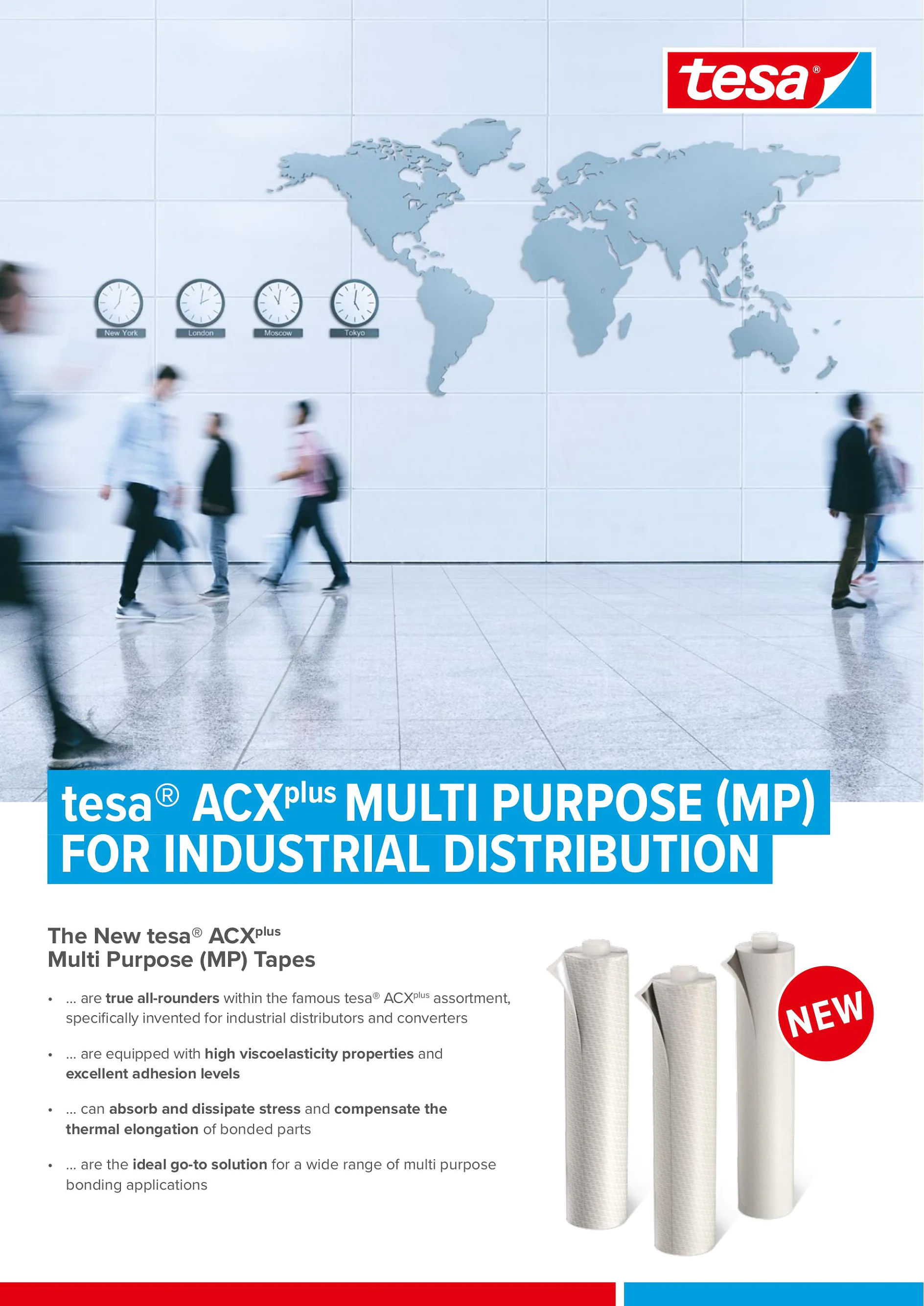

Complete acrylic foam tape assortment for all application requirements

Our wide product range fulfills all application requirements. For example, we offer our products in different thicknesses to fulfill design gap requirements or compensate for rough and uneven surfaces.

Our acrylic foam tapes are used in many markets, such as appliances, electronics, automtotive, and building components.

Our tesa® ACXplus acrylic foam tapes

With our tesa® ACXplus tape assortment, you can easily and quickly create a long-lasting bond of different materials. These high performing double-sided acrylic foam tapes offer you new options for aesthetically pleasing, secure, fast and permanent bonding applications. Rethink your design options and get inspired by watching our tesa® ACXplus video.

tesa® ACXplus assortment

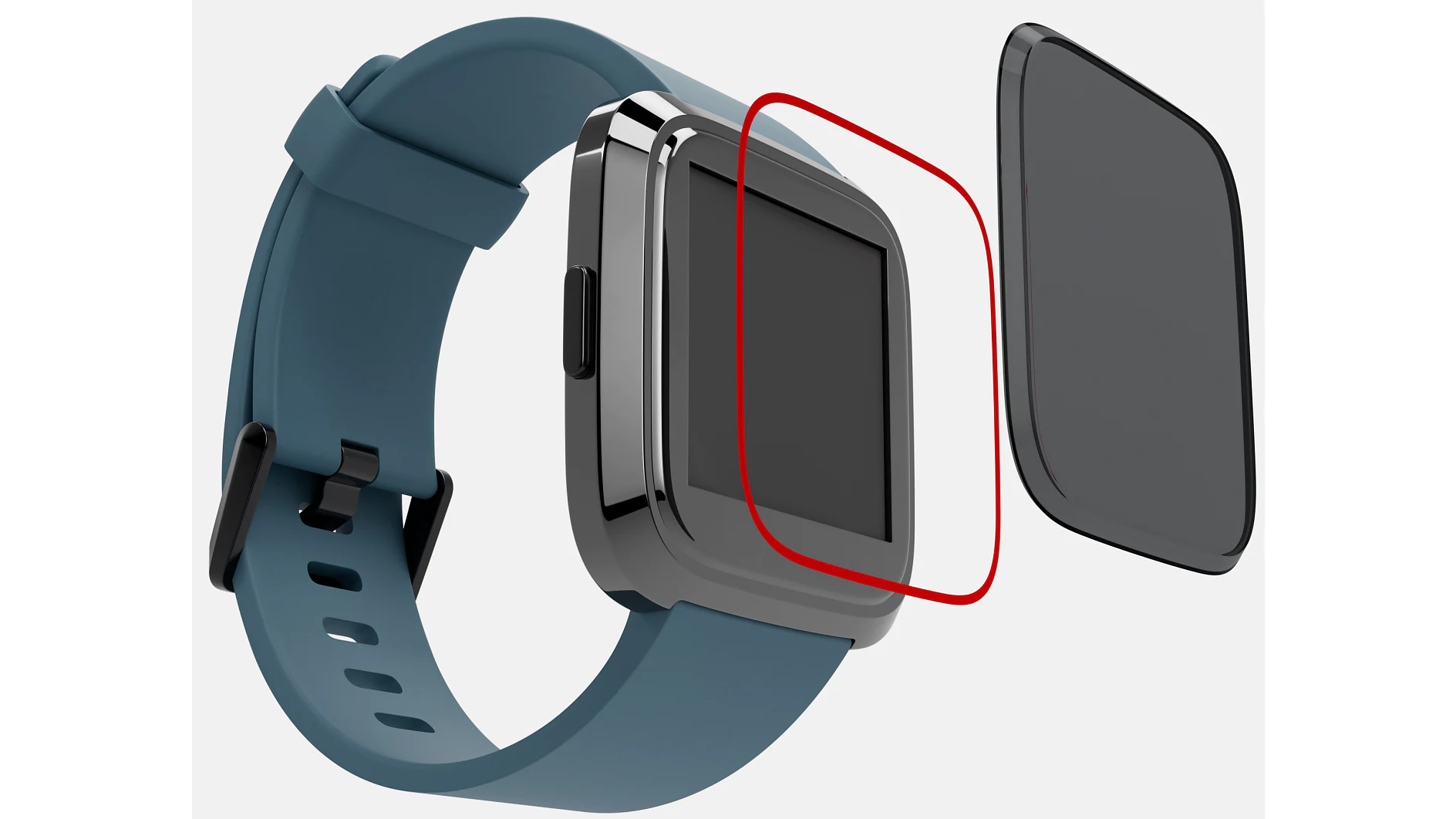

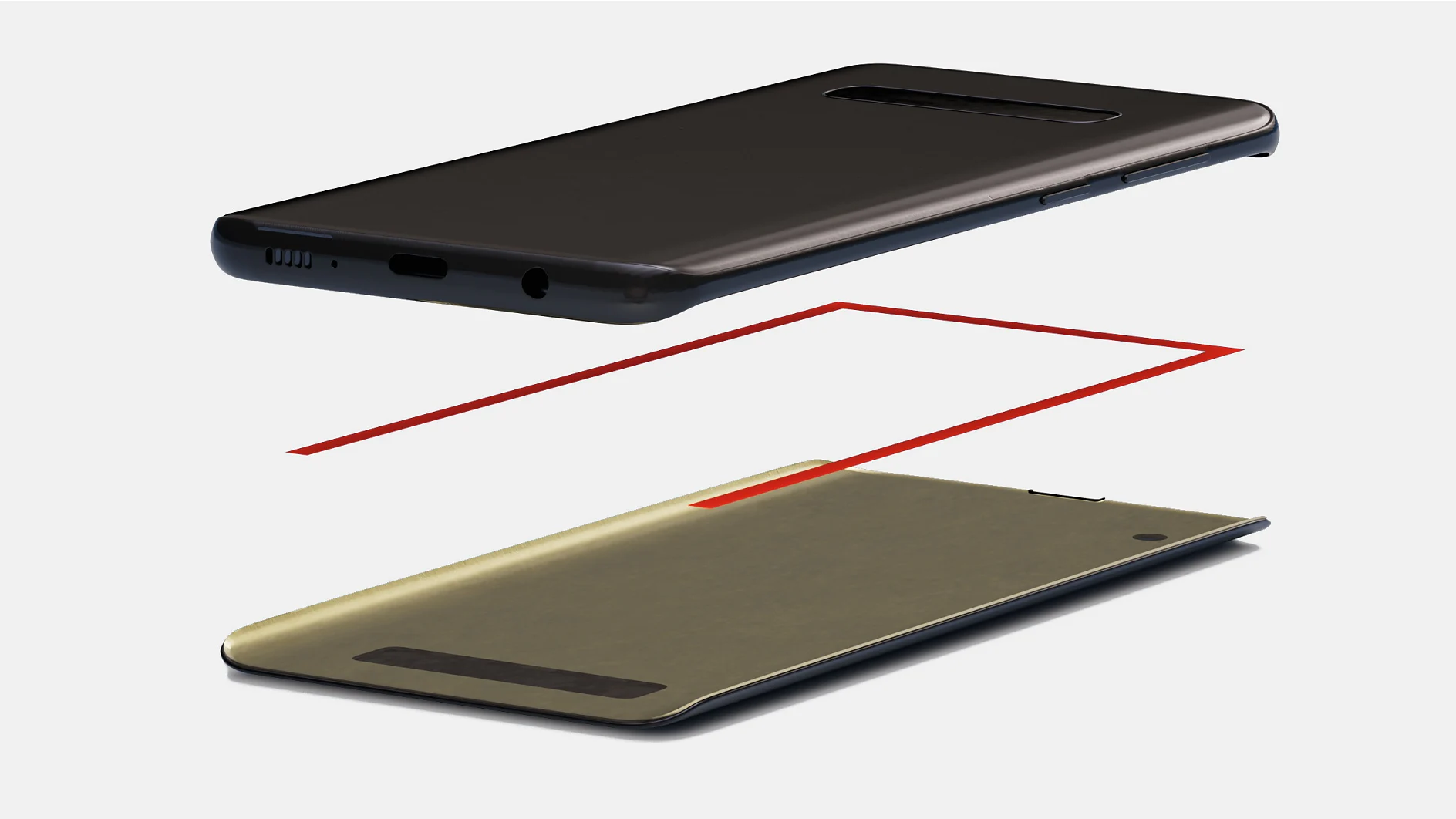

Acrylic foam tapes for low thickness applications

The bonding of substrates in electronic devices can be very challenging as the components are characterized by complex geometries and design gaps often require low thickness adhesive solutions. We have you covered with our high-performance acrylic foam tapes specifically developed for the consumer electronics industry.

Discover more about our acrylic foam tapes assortment by using our product finder.