Advantages of Double-Sided Adhesive Tapes - #BornToBuild

There are many reasons that speak in favour for the use of double-sided adhesive tape: Freedom of design, quality of the bond, and the assembly process to name a few.

There are many reasons that speak in favour for the use of double-sided adhesive tape: Freedom of design, quality of the bond, and the assembly process to name a few.

There are many reasons that speak for the use of double-sided adhesive tape. The freedom of design and the clean working method are just two examples. There is a clear benefit in using double sided tapes to baond materials together when compared with liquid glues and mechanical mounting systems.

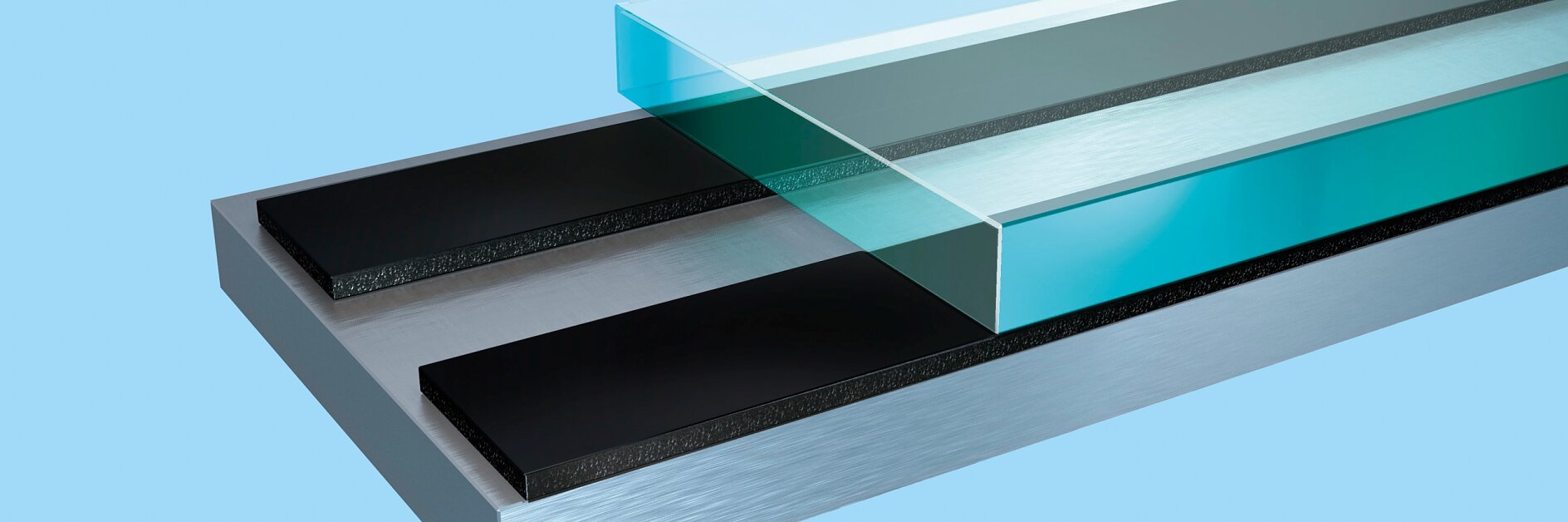

Using double sided tapes when carrying out interior fit outs in commercial or residential projects, can provide you with time savings as well as enable design freedom and increased safety, for example when attaching glass to metal, invisibly mounting mirrors to walls or adding intumescent seals to doors to prevent the spread of fire and smoke throughout the building.

| Double-sided tapes | Liquid glue | Mechanical fastening | |

|---|---|---|---|

| Compensation of irregular or uneven surfaces – gaps between bonded surfaces are eliminated | +++ | ++++ | + |

| Compensation of tension and stress dissipation – single bonding point with mechanical fasteners can lead to material breakage | ++++ | ++ | + |

| Shock absorption | ++++ | ++ | ++ |

| Reduced risk of corrosion | ++++ | ++++ | + |

| Sealing function – tape seals and protects against dust and moisture | ++++ | ++++ | ++ |

| Noise-dampening properties – sounds caused by vibration are eliminated | ++++ | +++ | + |

| Double-sided tapes | Liquid glue | Mechanical fastening | |

|---|---|---|---|

| Fast application process – elimination of curing time and reduction of complexity | ++++ | + | ++ |

| Healthy working environment and clean production sites | ++++ | ++ | ++ |

| Double-Sided Tapes | Liquid Glue | Mechanical Fastening | |

|---|---|---|---|

| Improved visual appearance – no damage to the material | ++++ | +++ | + |

| Invisible fastening – mounting of transparent materials | ++++ | +++ | + |