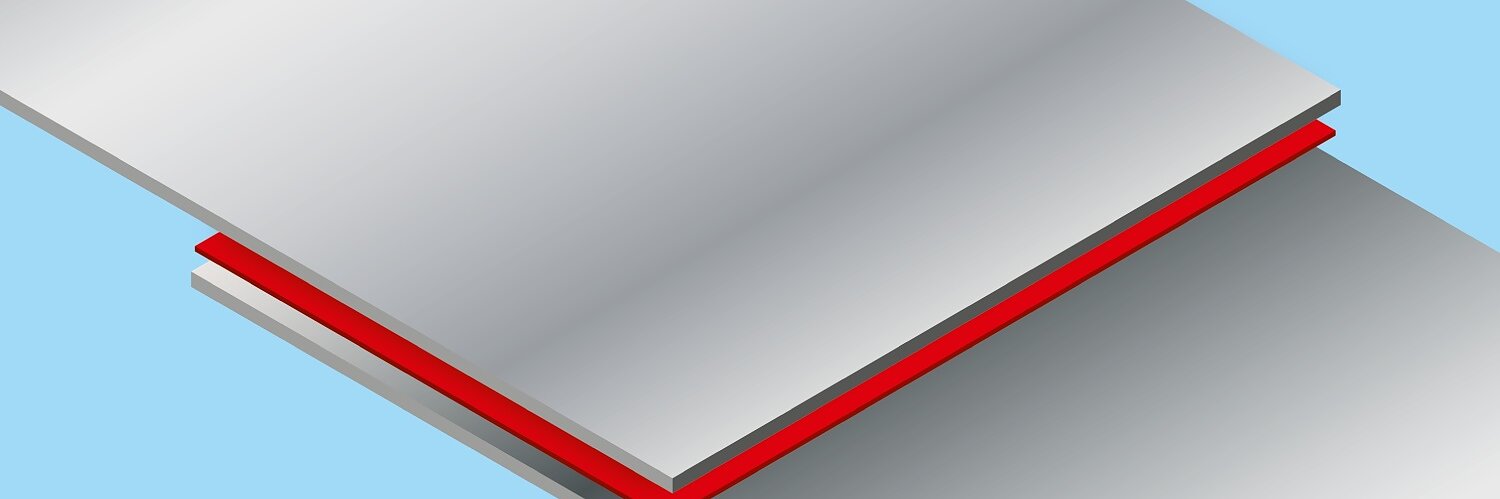

Metal Overlap Splicing

Double-sided adhesive tapes with high adhesion and heavy stress resistance offer great opportunities for high efficiency in metal-manufacturing processes.

Double-sided adhesive tapes with high adhesion and heavy stress resistance offer great opportunities for high efficiency in metal-manufacturing processes.

Metal coils are spliced to run the metal continuously through finishing and treatment lines. The two most common splicing techniques used are metal overlap splicing and metal butt splicing. For overlap splicing we provide double-sided self-adhesive-tape solutions with proven adhesive systems to enable high shear-stress resistance at high temperatures, as well as a tensile-resistant backing to compensate for web stress.