Wafer-based solar modules

Wafer-based crystalline silicon (c-Si) modules continue to be the backbone of solar power production

Wafer-based crystalline silicon (c-Si) modules continue to be the backbone of solar power production

Solar energy will expand even faster in the future, and the efficiency during production will become even more important. Over the years, we have gained profound expertise in solar markets and have developed cost-effective adhesive solutions together with our customers. They have proven themselves in practice, are ready to use, and available globally.

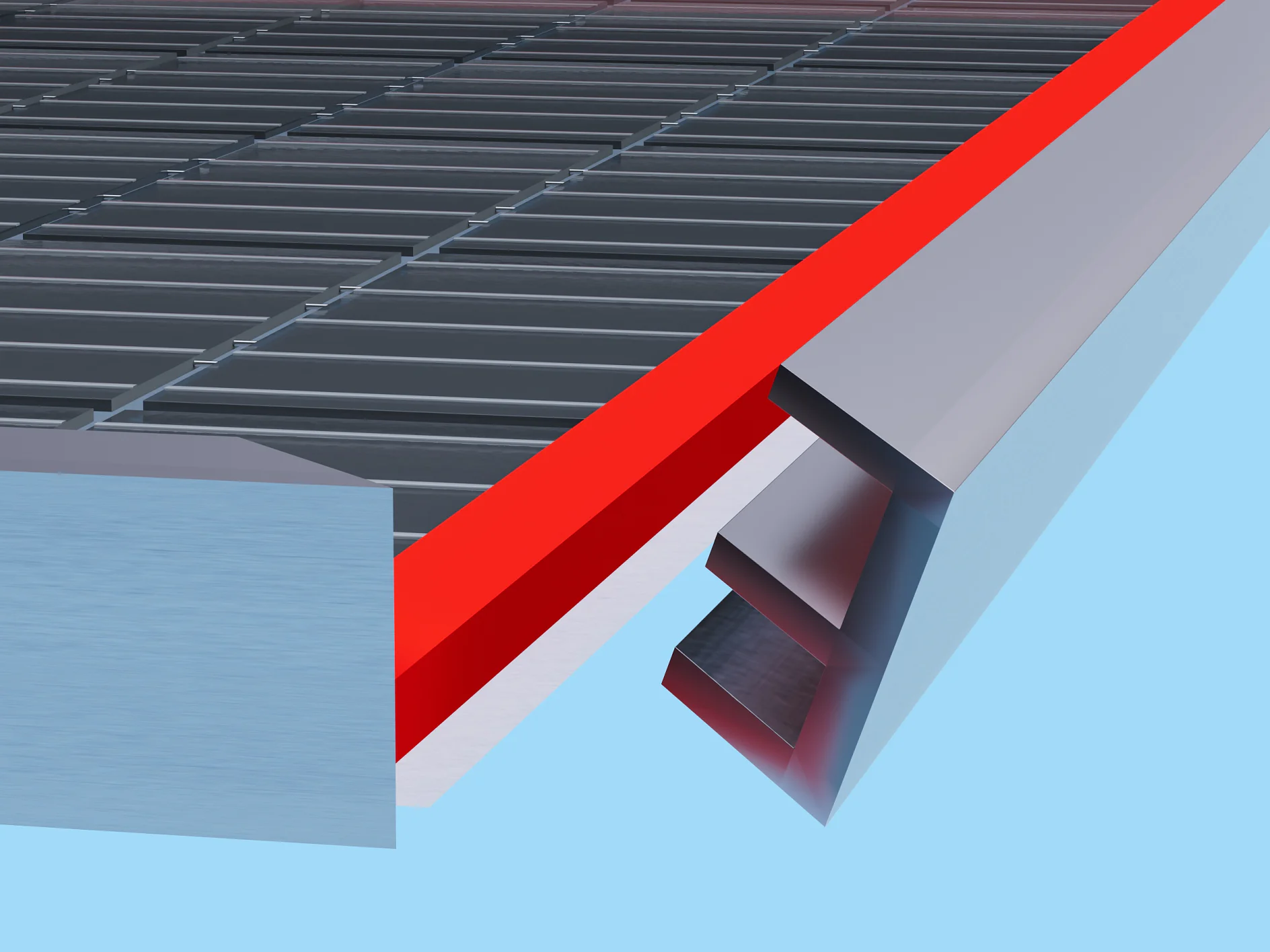

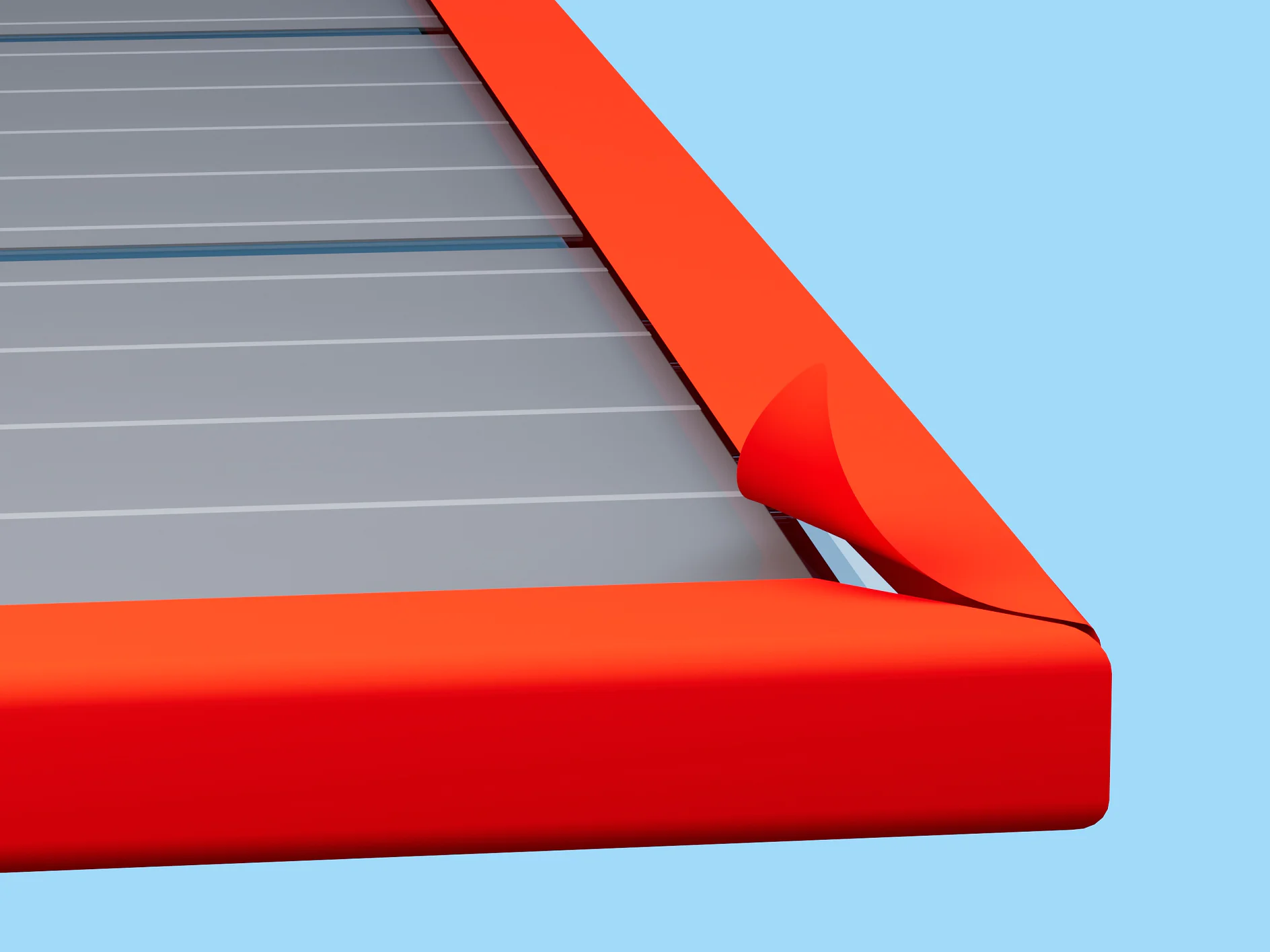

Solar frame bonding calls for a very durable solution, providing reliable attachment and weather-proof sealing at the same time. For more than a decade our high quality PE foam tapes have been a trusted solution for this demanding application, offering an aesthetic finish and a fast, clean, and simple assembly process thanks to immediate holding strength (no curing time) and no mess associated with liquid glues.

tesa® 62510 double coated PE foam

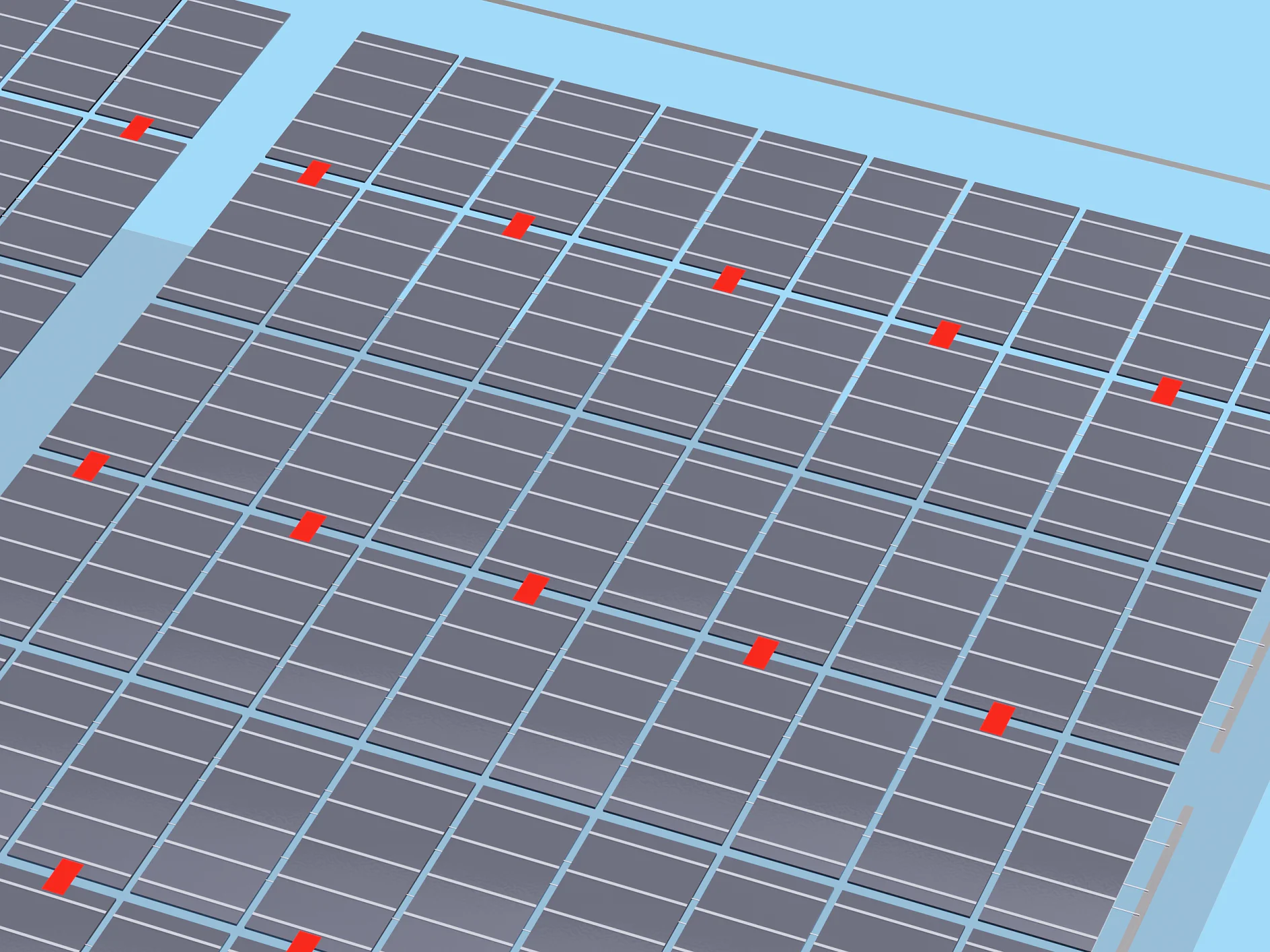

During the lamination process, solar cell strings need to be perfectly aligned and kept in position. Any solution has to withstand the heat required to melt the encapsulant and there cannot be any interaction between the materials in use in order to ensure a bubble-free and homogenous sealing and a perfect adhesion between the different layers of the PV module. Our industry-proven tapes recommended for this application keep cells and strings in place during the lamination process and are especially designed for good compatibility and durability.

tesa® 4129 - Transparent PET tape

During the lamination process, there is a need to mask off holes in the back sheet. Any applied tape needs to securely withstand the high temperatures of the lamination process, and easily remove after the laminate is ready.

tesa® 50600 - PET film tape with silicone adhesive

During the encapsulation process of frameless double glass modules, there is a need for single-sided tapes to prevent contamination of the equipment and form an aesthetic edge. Upon the process' completion, the tape needs to easily remove from the module.

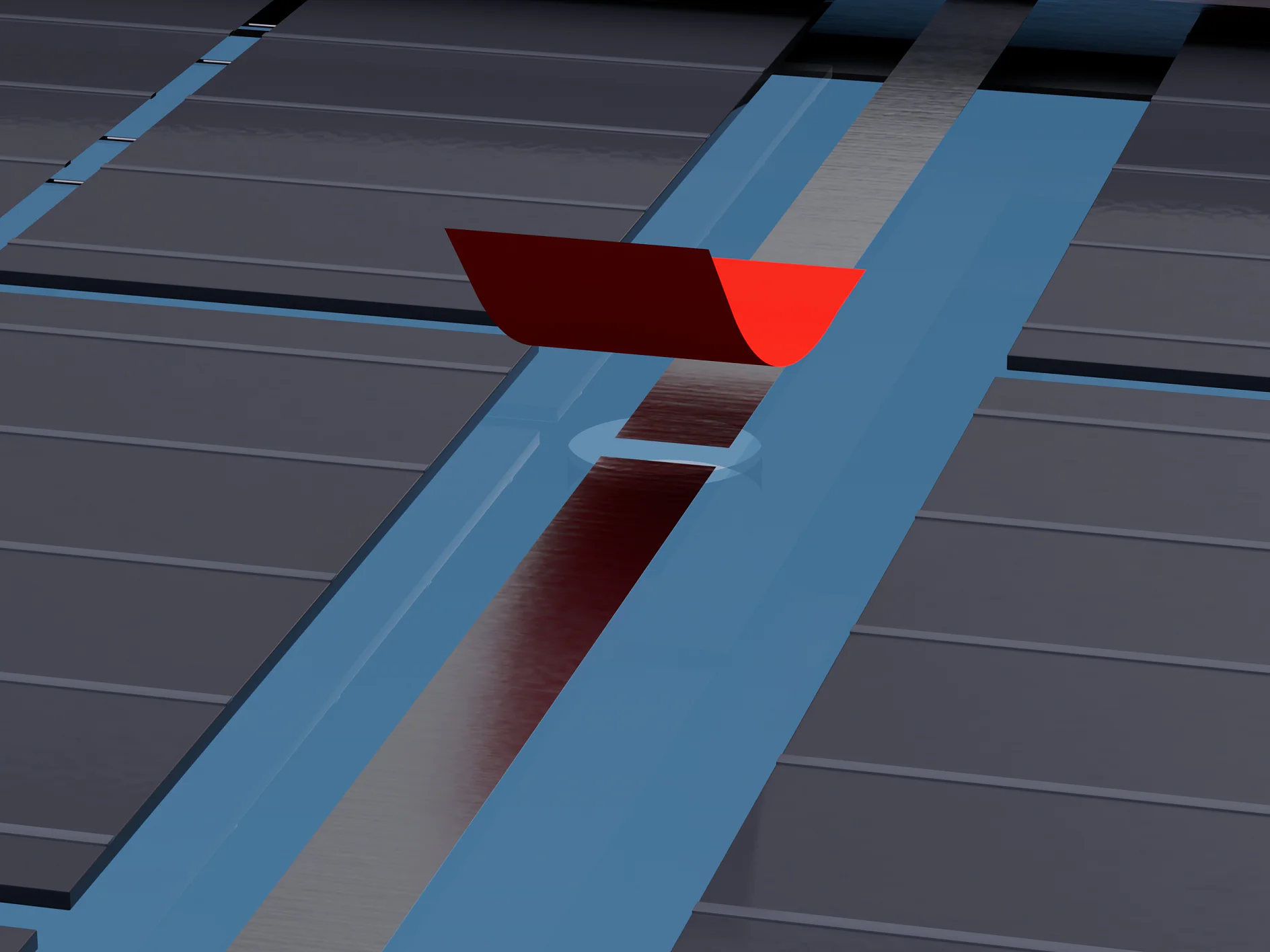

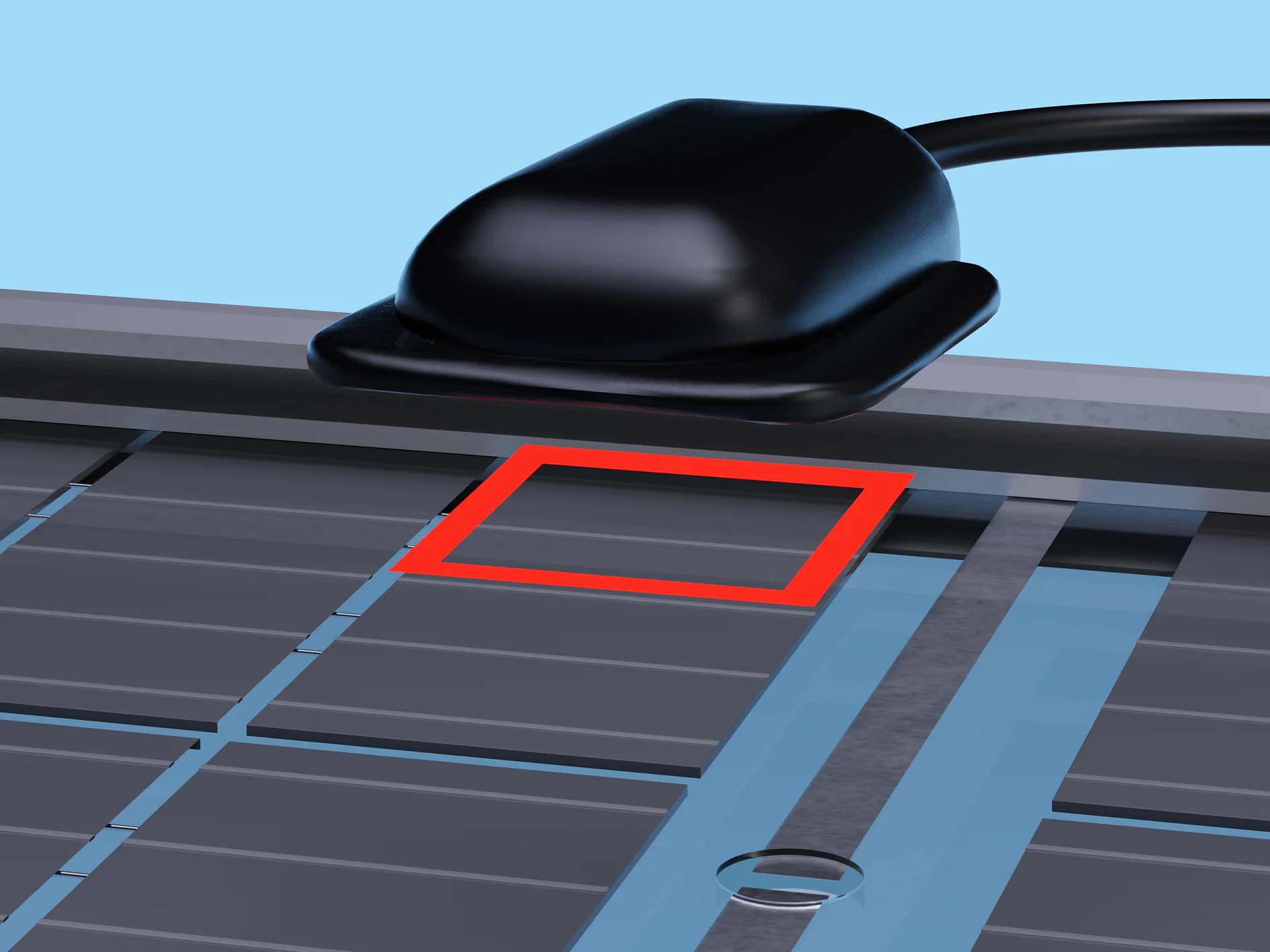

For temporary bonding of the junction box in combination with liquid adhesives. In addition to the spacer function, our adhesive tapes provide fast initial bonding and help implement a reliable and efficient production process.

tesa® 62510 – Double-coated PE foam tape

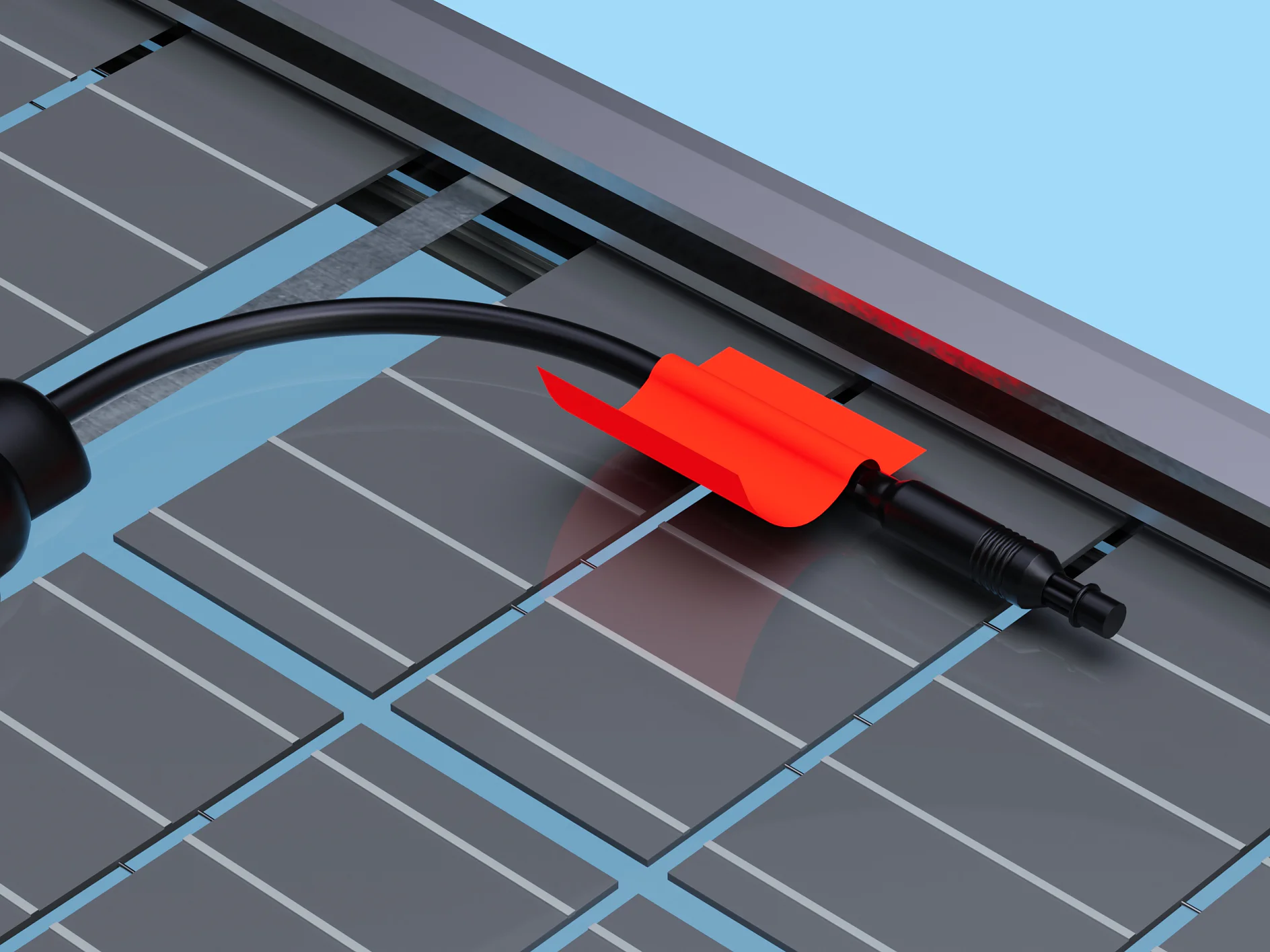

During transport and installation, junction box cables need to be securely kept in place to avoid damage. Any tape used for cable fixation must also be easy to remove after shipping to facilitate efficient installation processes.

tesa® 64283 – MOPP film transport securing tape