Stretch release tape – Innovative solutions for your business

Modern industrial products must deliver performance, efficiency, and sustainability throughout their entire life cycle. Stretch release tape solutions combine permanent bonding strength with controlled, residue-free removal, enabling manufacturers to rethink assembly and product life cycle strategies.

From consumer electronics devices over home appliances to automotive systems, our stretch release tapes deliver secure hold when needed and clean detachment when required – supporting efficient production processes and circular product design. If you would like more information or are interested in a tailored solution for your application, please contact our experts

How stretch release technology works

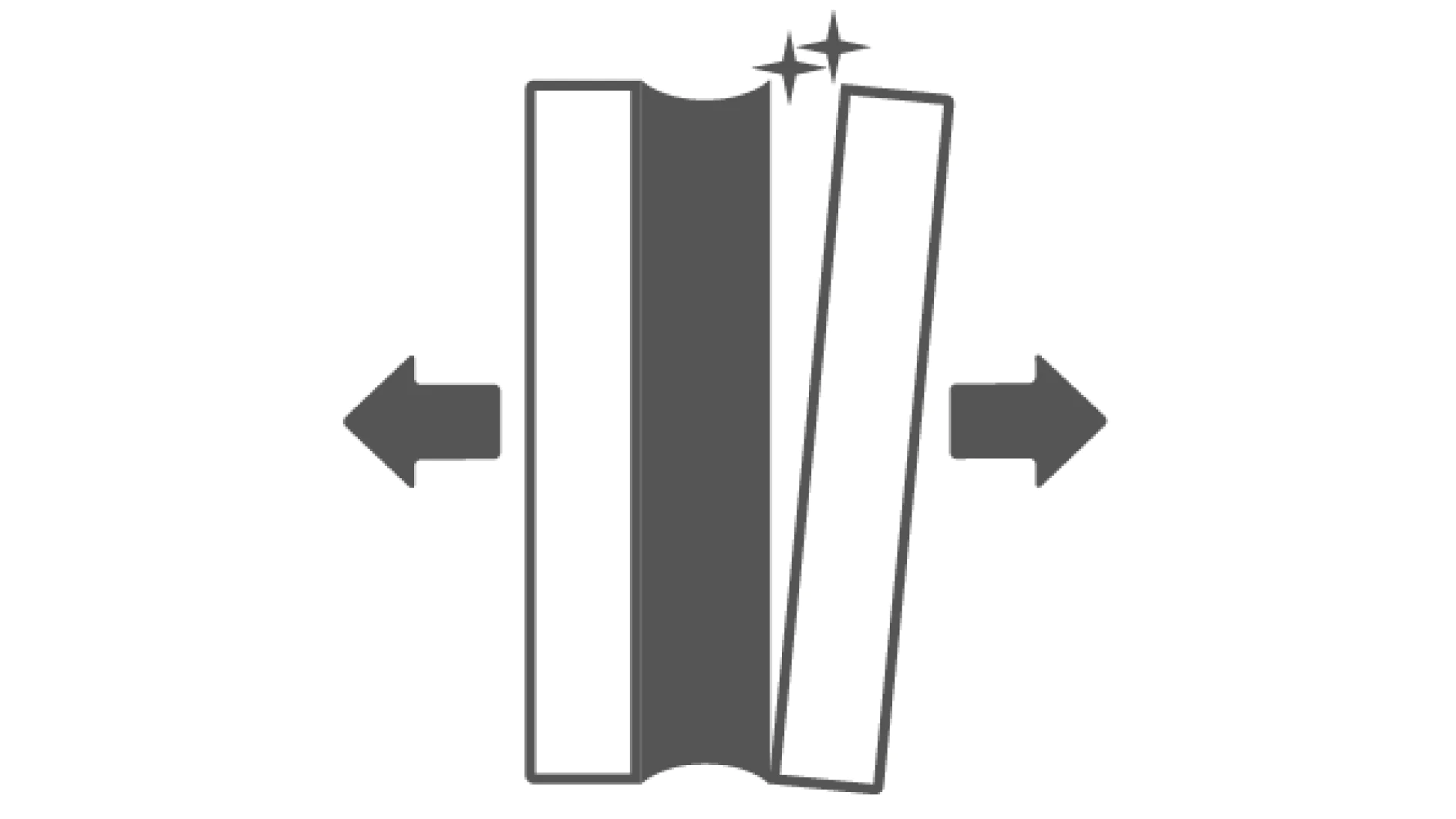

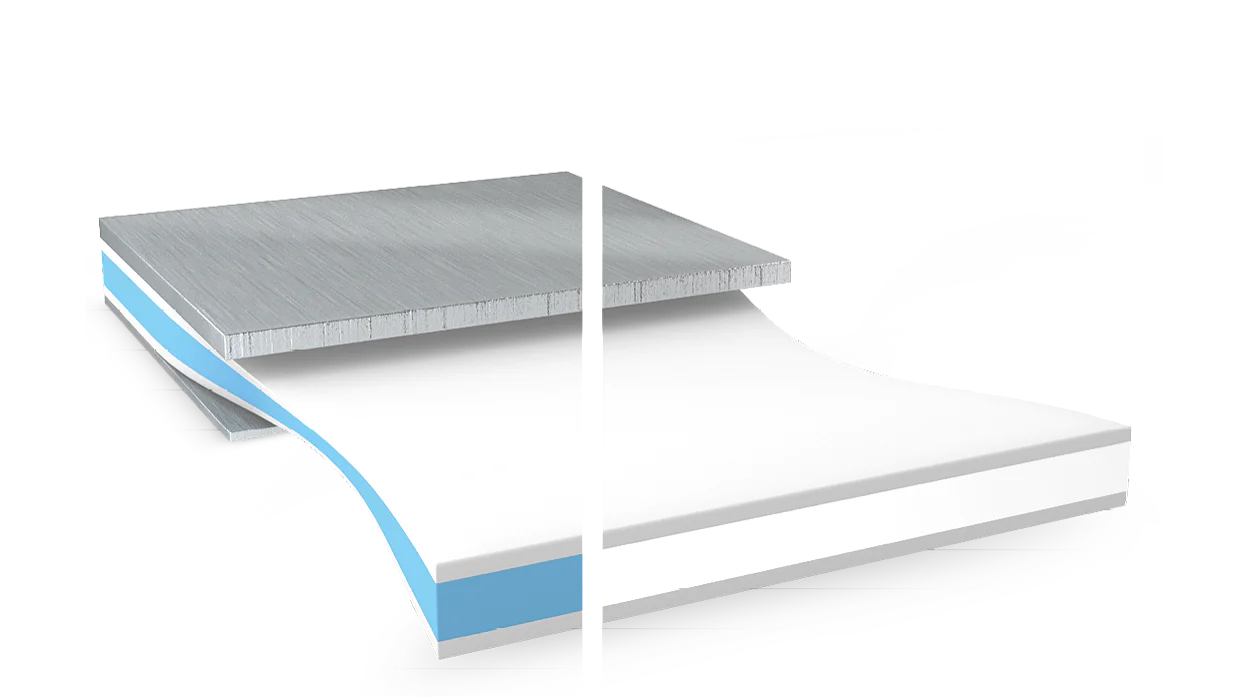

The stretch release mechanism is a mechanical debonding process. Based on our Bond & Detach® technology, stretch-release tapes were developed and engineered for demanding industrial applications, enabling reliable bonding combined with clean and controlled removal. When the integrated tab is pulled, the adhesive stretches and elongates, significantly reducing its bonding strength. This controlled stretching ensures a clean and controlled separation from the substrate through mechanical stretching.

This simple yet robust principle enables what we call Debonding on Demand (DoD) – the ability to detach components precisely when needed. Stretch release is the first and most established DoD technology and serves as the foundation of our Bond & Detach® product family.

Stretch release tape with a unique removability concept

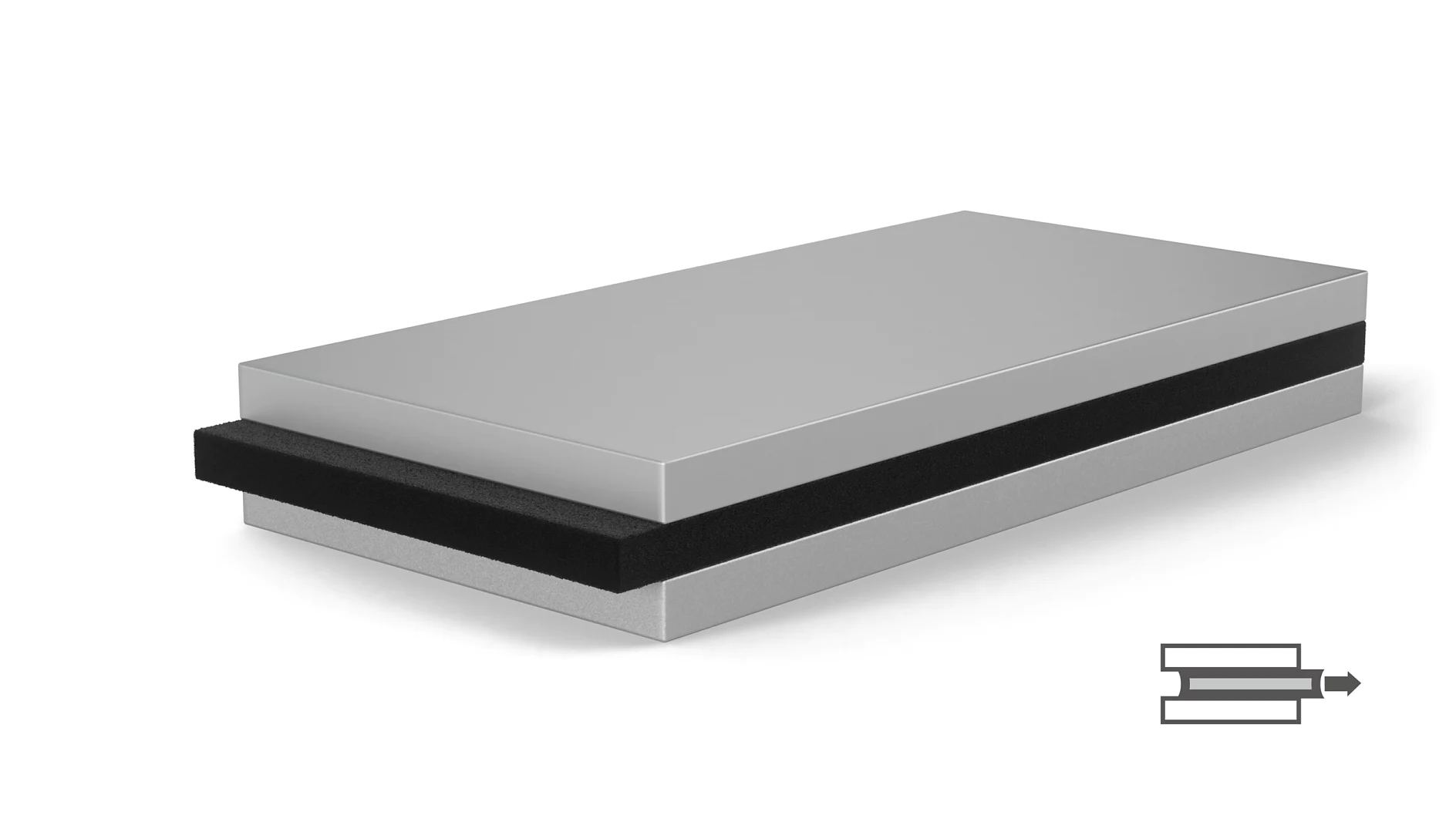

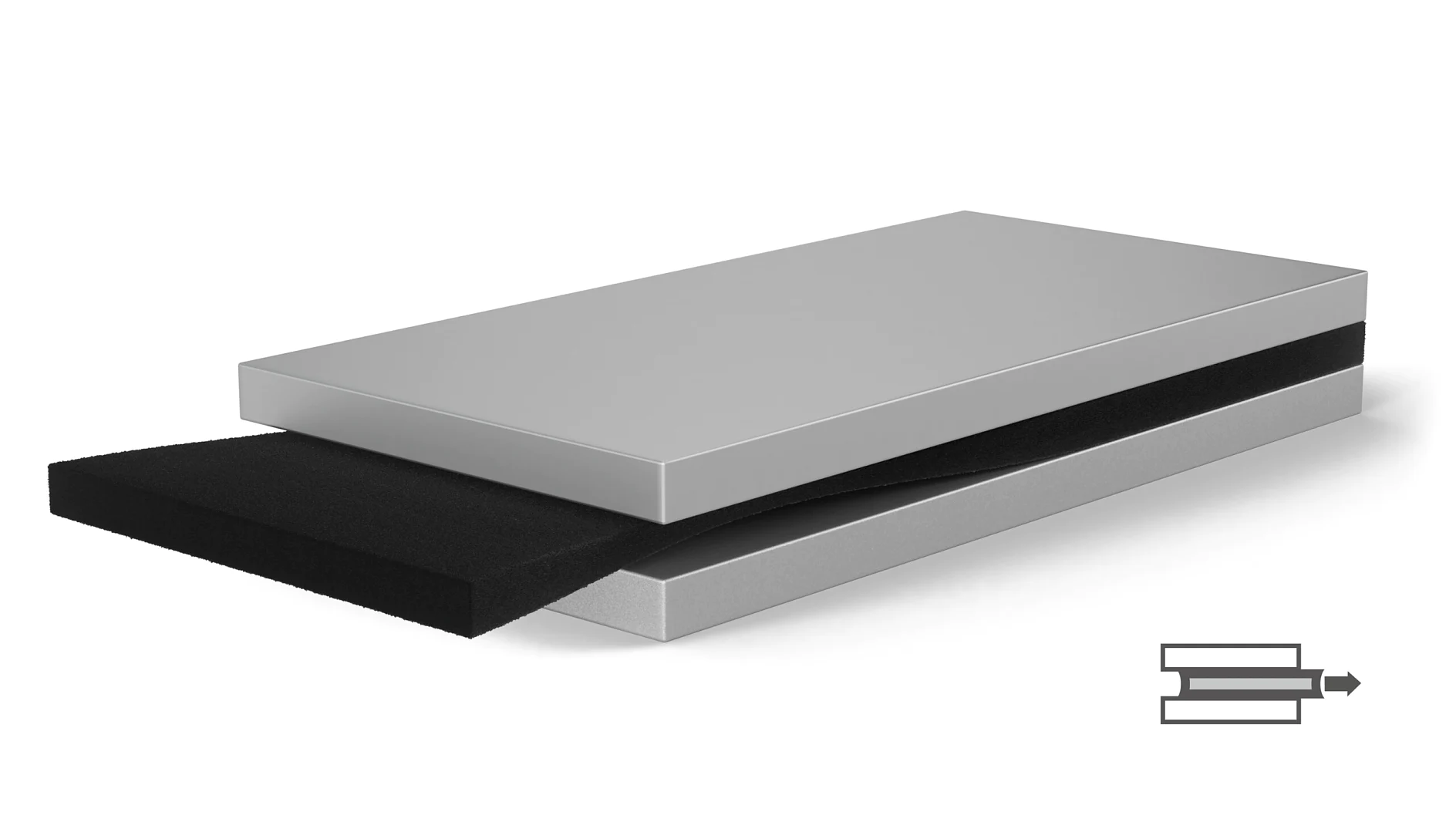

Our stretch release tapes combine very high bonding strength with controlled, residue-free removability, making them suitable for both permanent and reversible fixation in demanding industrial environments.

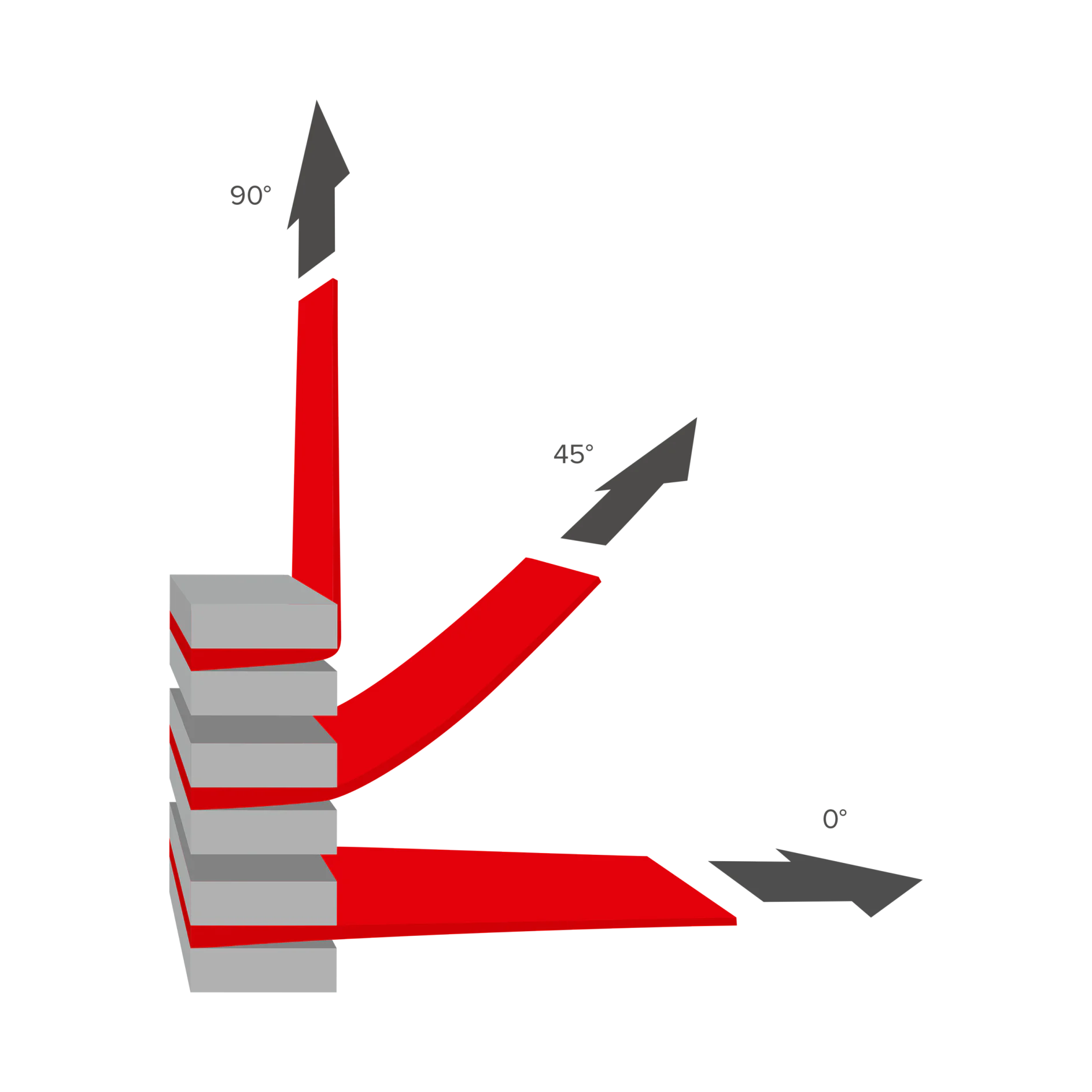

The advanced adhesive technology delivers high initial and long-term adhesion, even on low surface energy (LSE) substrates, and maintains reliable performance under mechanical stress, vibration, and temperature or humidity exposure. When required, the bond can be released at any stage of the product life cycle by stretching the tape at an angle of up to 90°.

Unlike conventional double-sided adhesive solutions, stretch release tapes require no tools, heat, solvents, or additional equipment for debonding. This reduces the risk of surface damage, shortens rework and repair times, and supports reuse and recycling of high-value components. Selected foamed variants additionally provide enhanced shock absorption, ensuring reliable protection for sensitive components such as batteries.

Key performance characteristics of our stretch release tapes include:

- High immediate and final bonding strength, even on LSE materials

- Clean debonding by mechanical stretching

- High impact resistance and durability under environmental stress

- Advanced polymer architecture with high internal strength and elasticity

- Controlled reduction of adhesive contact area during stretching for safe, predictable removal

By enabling secure bonding during use and clean removal for repair, replacement, or recycling, our stretch release tapes deliver a flexible bonding concept that supports efficient production processes, modern product architectures, and sustainable manufacturing strategies.

Where stretch release tapes are used

Our stretch release tapes provide a versatile and reliable bonding solution for a wide range of industrial applications. Their combination of high adhesion, residue-free removability, and impact resistance makes them ideal for use in electronics, home appliances and the automotive sector, supporting secure mounting, flexible rework, and sustainable product design.

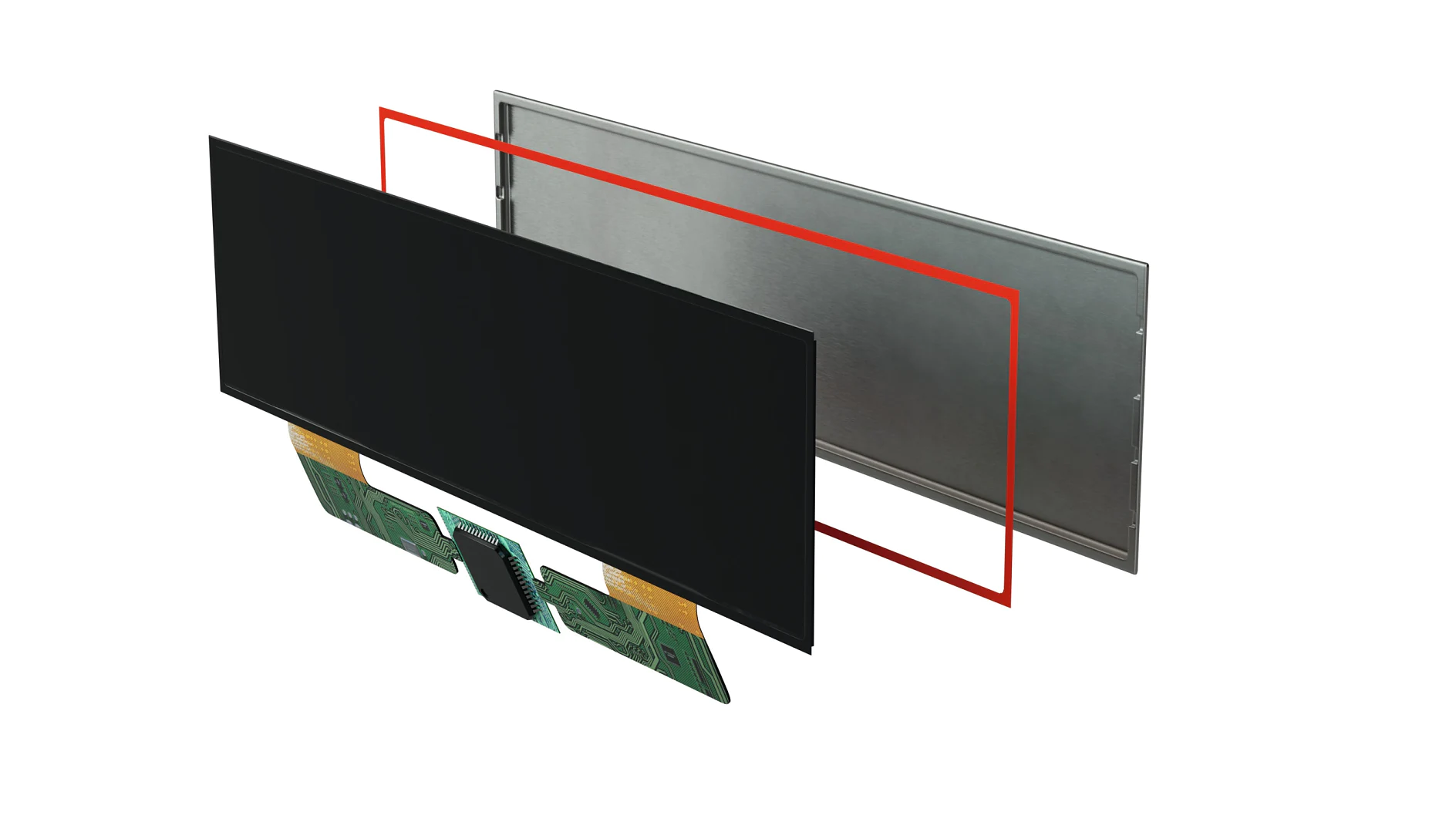

Debonding a display and battery modules

Debonding a display

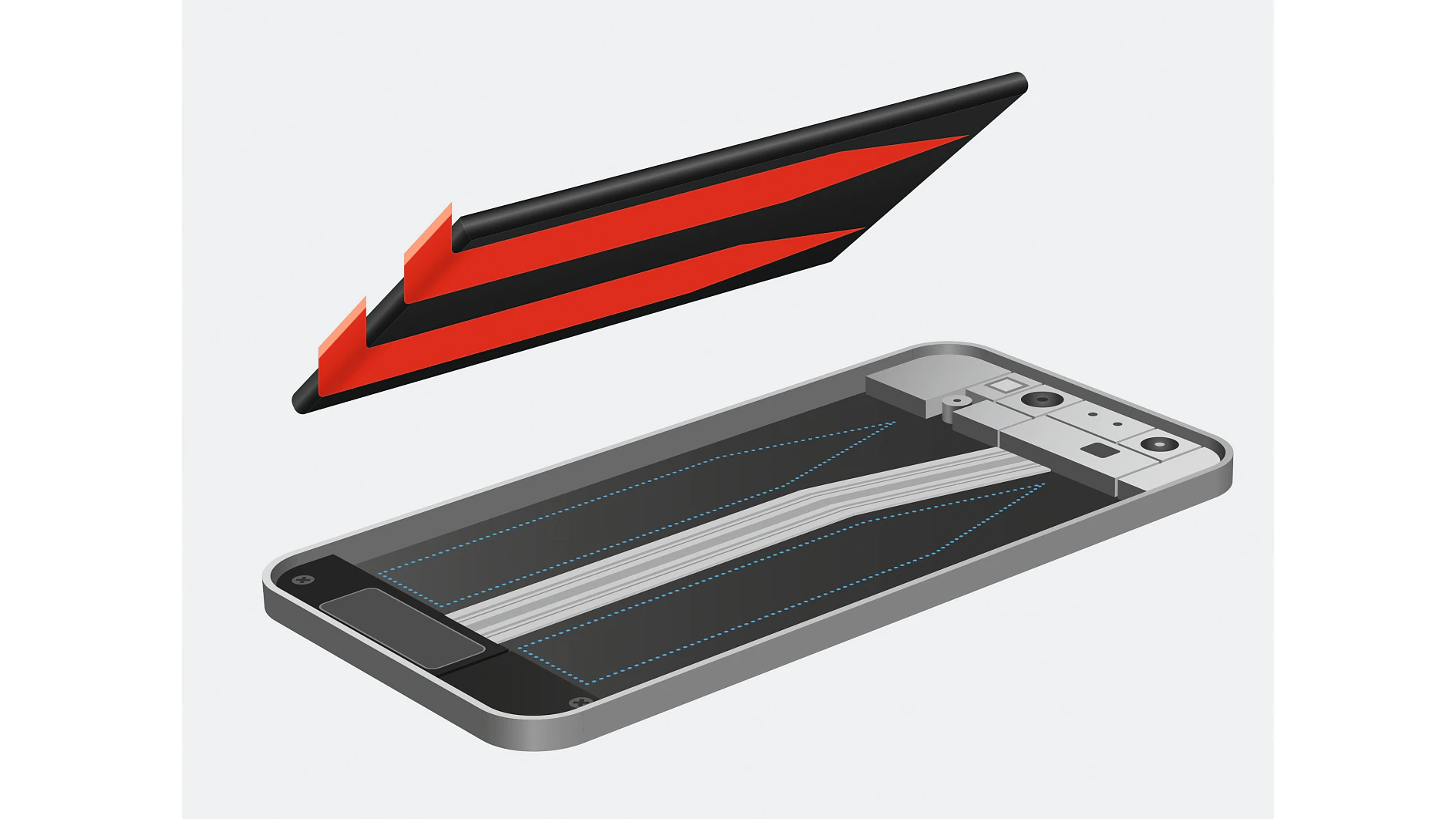

Debonding battery modules

Explore our stretch release tapes

We provide a wide portfolio of stretch release tapes, developed to meet the specific performance and durability requirements of applications such as automotive systems and electronic devices. For example, in the automotive sector, tesa® 76565 Bond & Detach is a 500 µm double-sided stretch release tape designed for reliable bonding of high-value components over the full lifetime of a vehicle. It offers high initial adhesion combined with resistance to heat, humidity, and UV exposure, making it suitable for demanding applications such as display mounting, ADAS components, and e-mobility systems. The tape enables rework during production and separation of bonded parts during service or end of life, without the need for heat, chemicals, or additional processing.

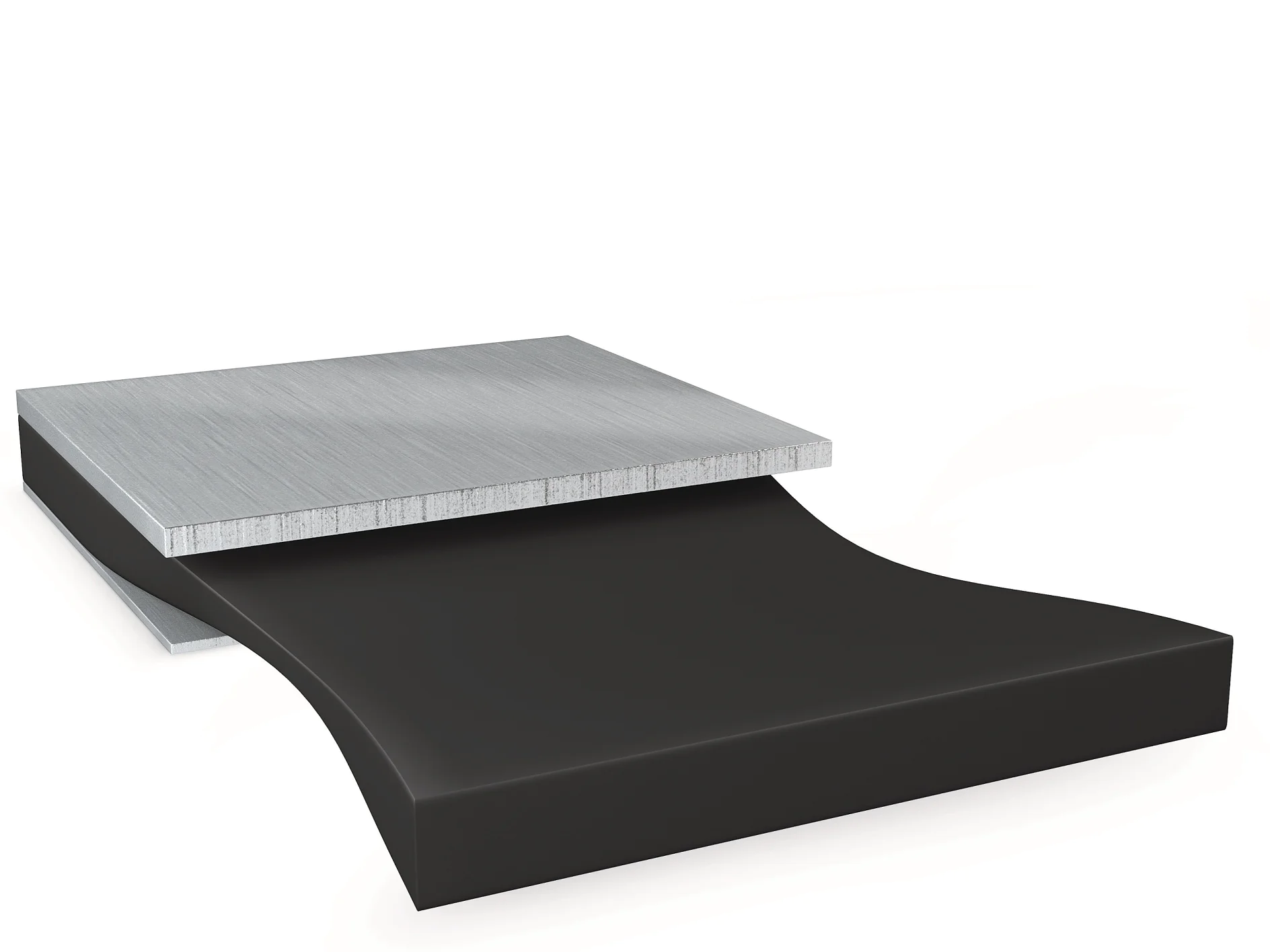

In electronics, the tesa® 770xx Bond & Detach series is a foamed stretch release tape developed to meet the high shock and space requirements of modern mobile devices. It provides fast and secure battery mounting in smartphones and other portable electronics, while its shock-absorbing structure offers significantly increased impact resistance. At the same time, the series maintains the benefits of controlled, clean debonding, supporting efficient assembly, battery replacement, and recycling processes.

These two examples illustrate how our stretch release tapes are tailored to specific industry requirements. Beyond these solutions, the portfolio includes a wide range of additional products designed to meet different performance, substrate, and process demands.

Products

FAQs

What is a stretch release tape?

A stretch release tape is a double-sided adhesive tape that can be removed cleanly by stretching it, significantly reducing bonding strength without leaving residue.

Can stretch release tapes be used for permanent mounting?

Yes. Our stretch release tapes are designed for permanent fixation while still allowing controlled removal when needed. For example, tesa® 76565, remains debondable over the entire product life cycle (e.g., the lifetime of a vehicle), enabling repair, rework, or recycling whenever needed.

Are tools required for debonding?

The stretch release mechanism allows for manual, machine-assisted, or fully automated debonding. No additional triggers such as heat are needed in the debonding process.