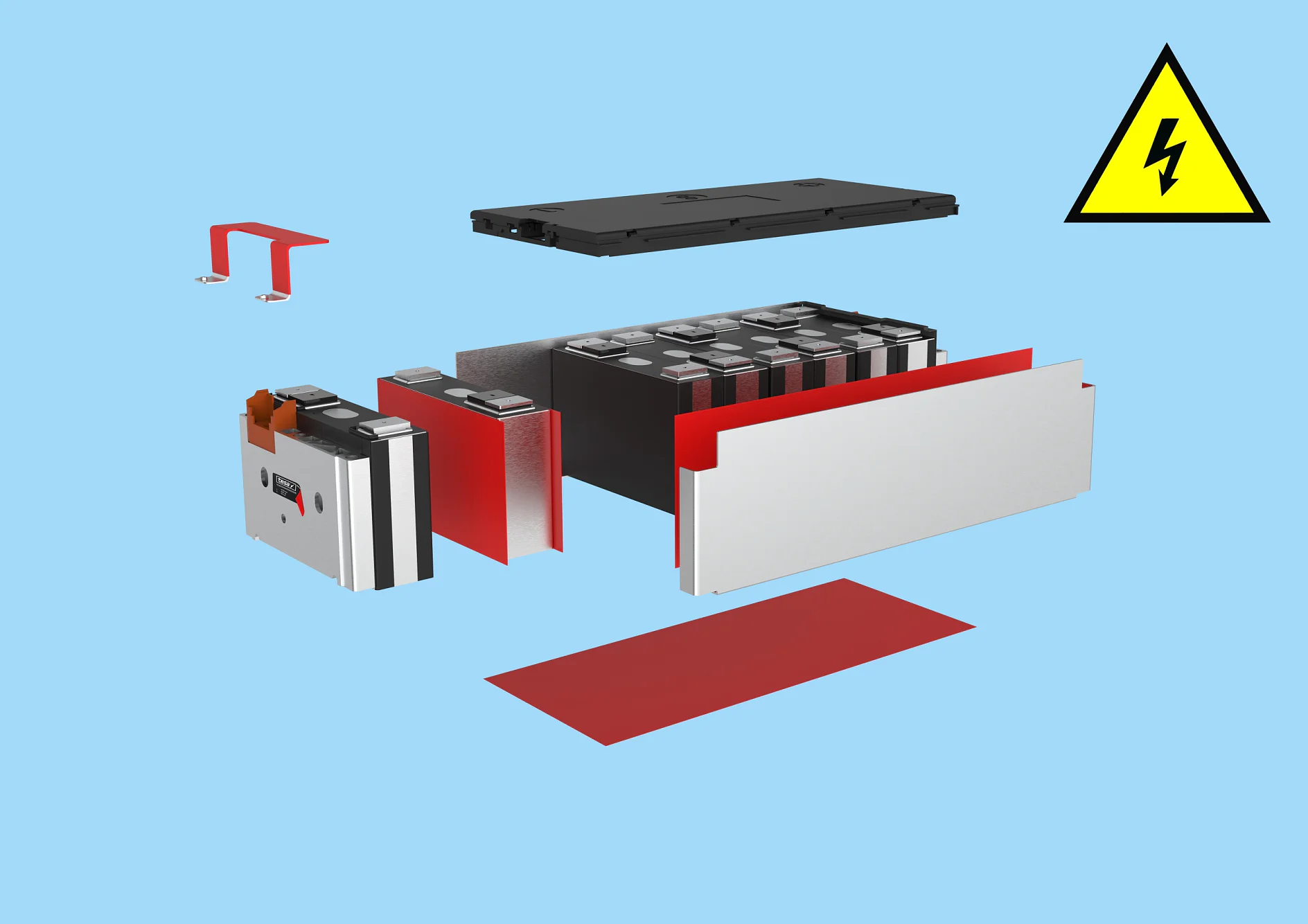

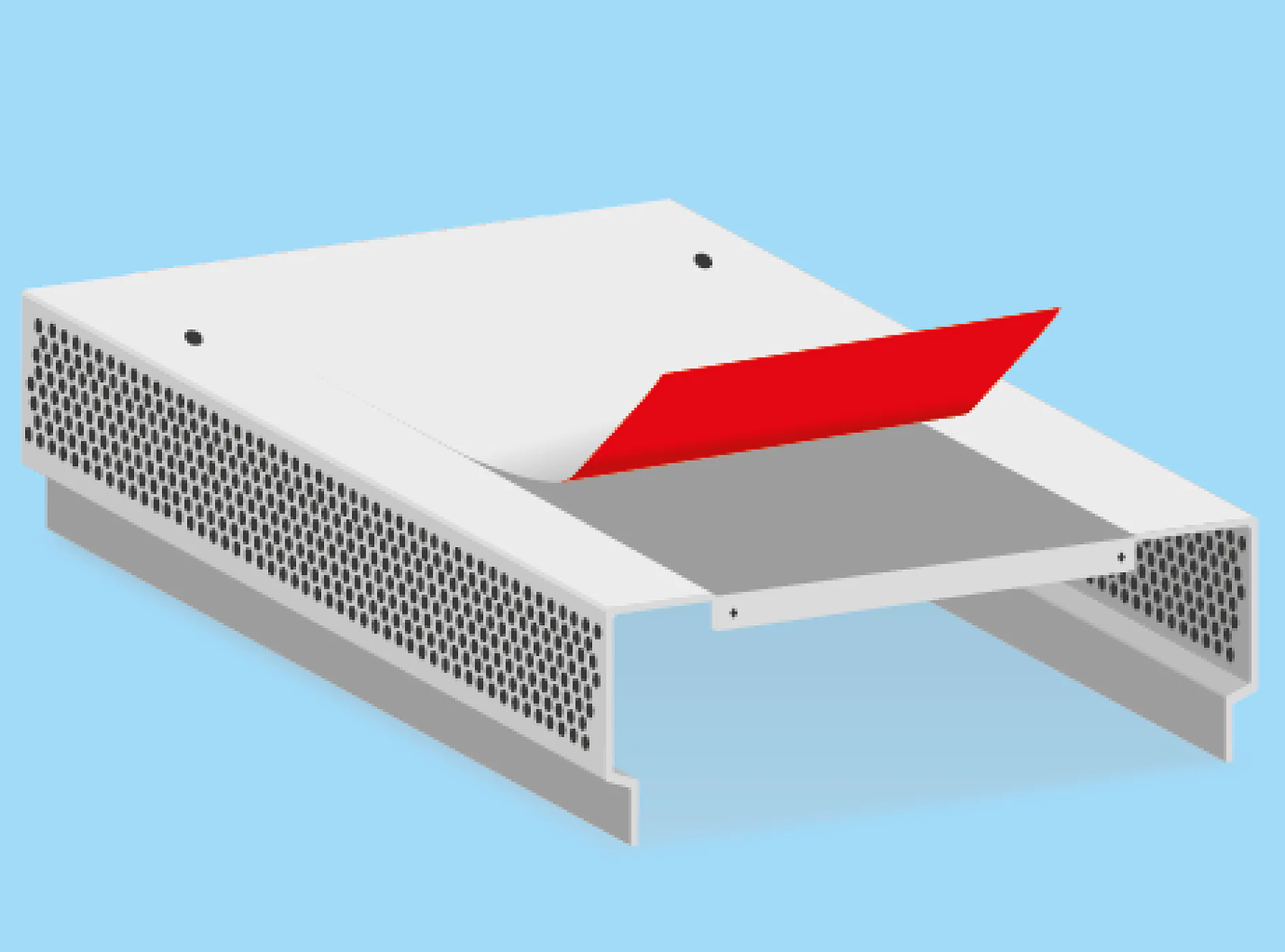

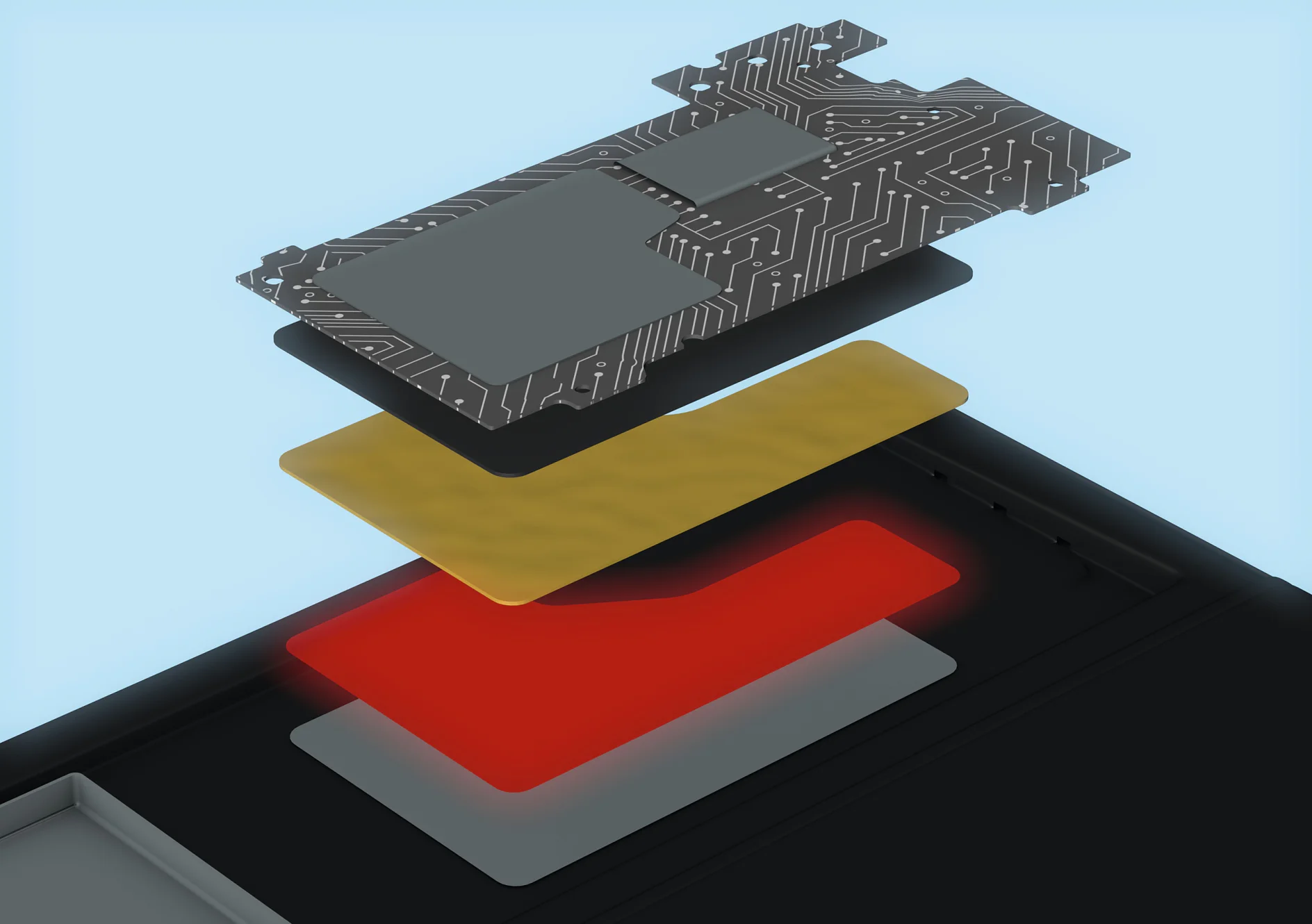

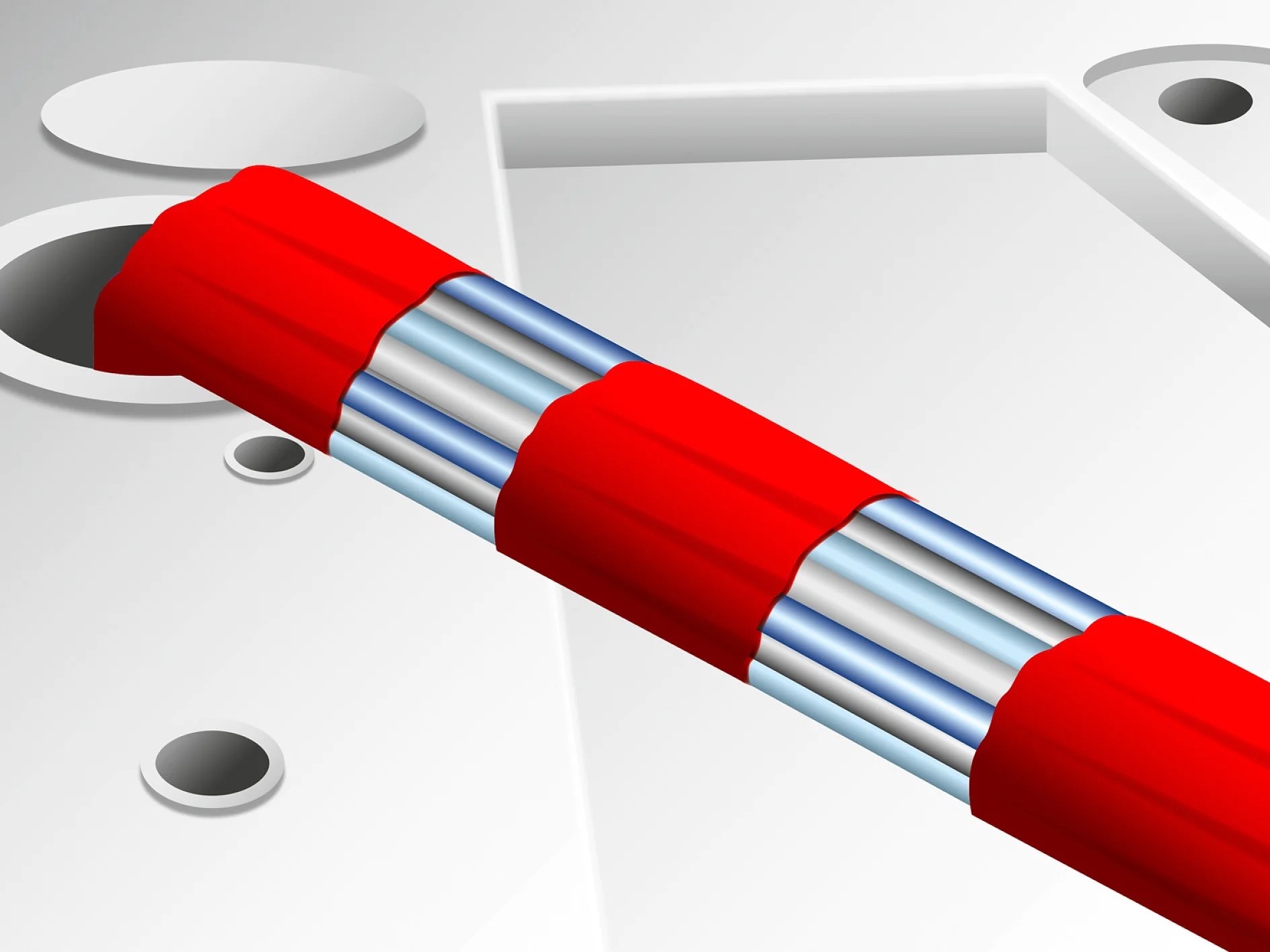

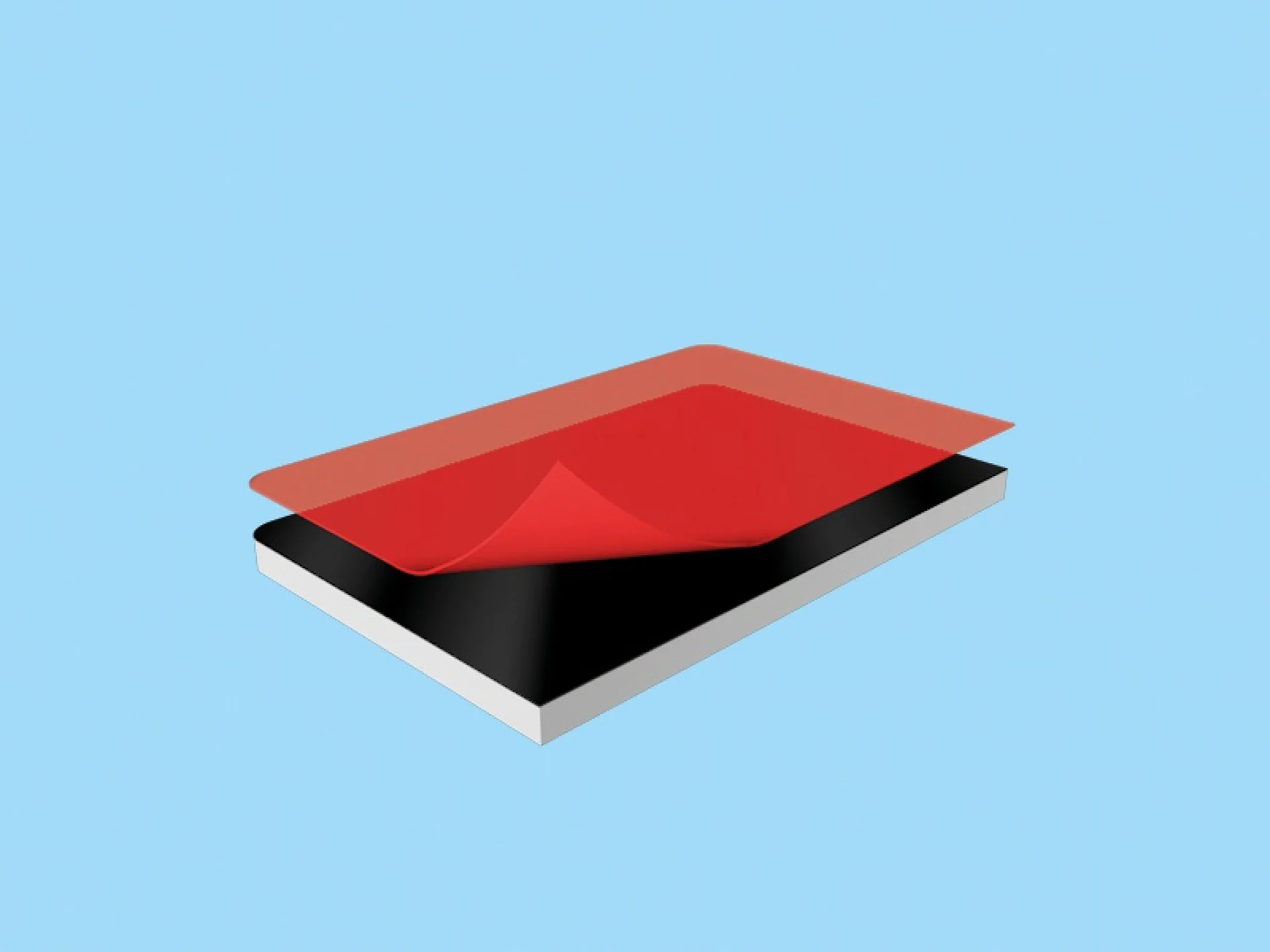

01Grounding and EMI shielding tape

Effective grounding and electromagnetic shielding tapes are vital for protecting server systems from electrical noise disruptions. We offer a range of EMI shielding tapes, including the tesa® 602xx, known for its strong adhesion and robust interference protection, and the tesa® 603xx, which excels in damp heat conditions. By choosing our electromagnetic shielding tape solutions, you ensure the reliability and performance of your server systems, safeguarding them against potential electrical noise threats.