Laptops are one of the most popular and versatile electronic devices for both businesses and individuals. Consumers worldwide value them for their high performance, mobility, and functionality in a compact and sleek design.

With growing consumer demands for more features and functionality, designing and assembling ever more powerful yet lightweight laptops can pose a headache for manufacturers.

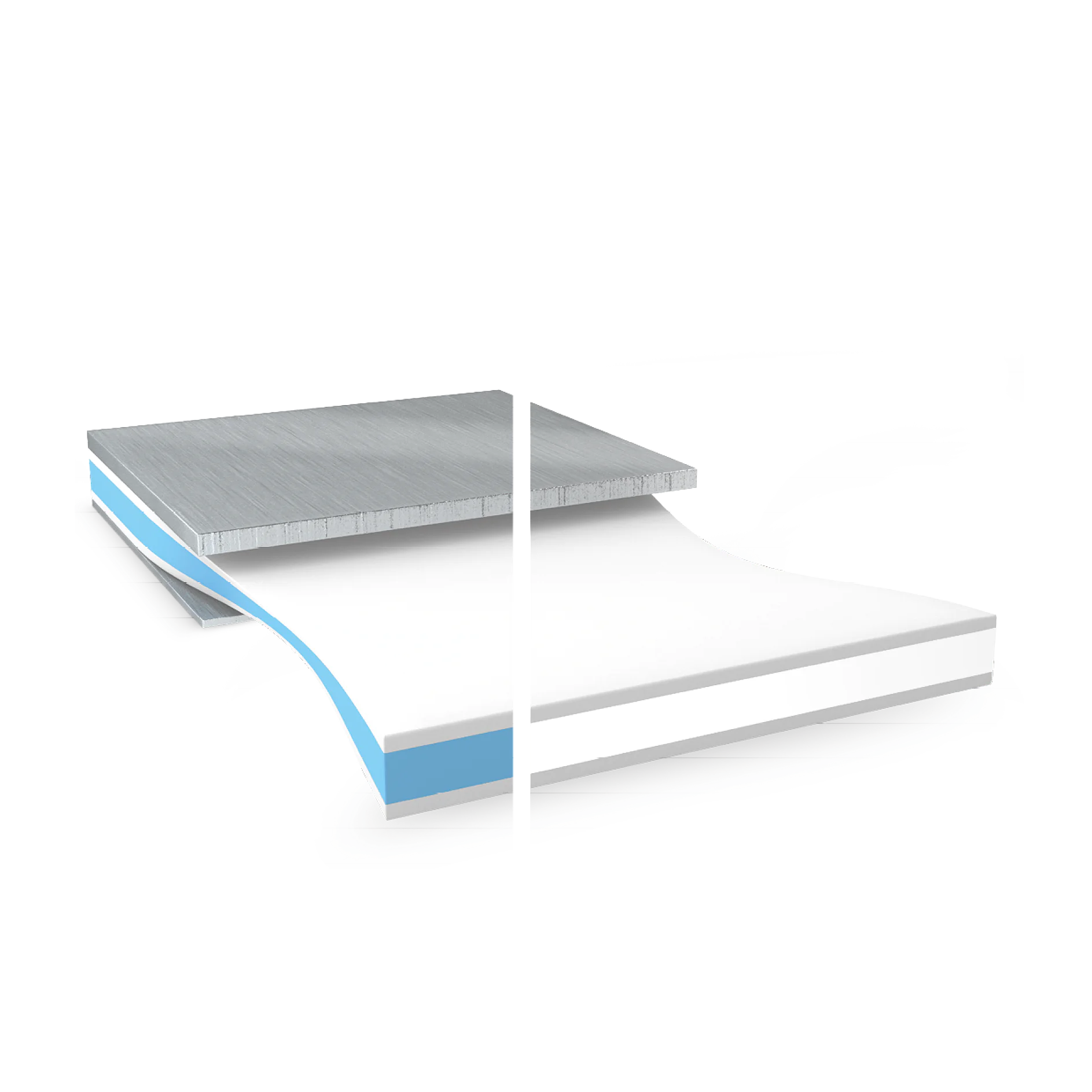

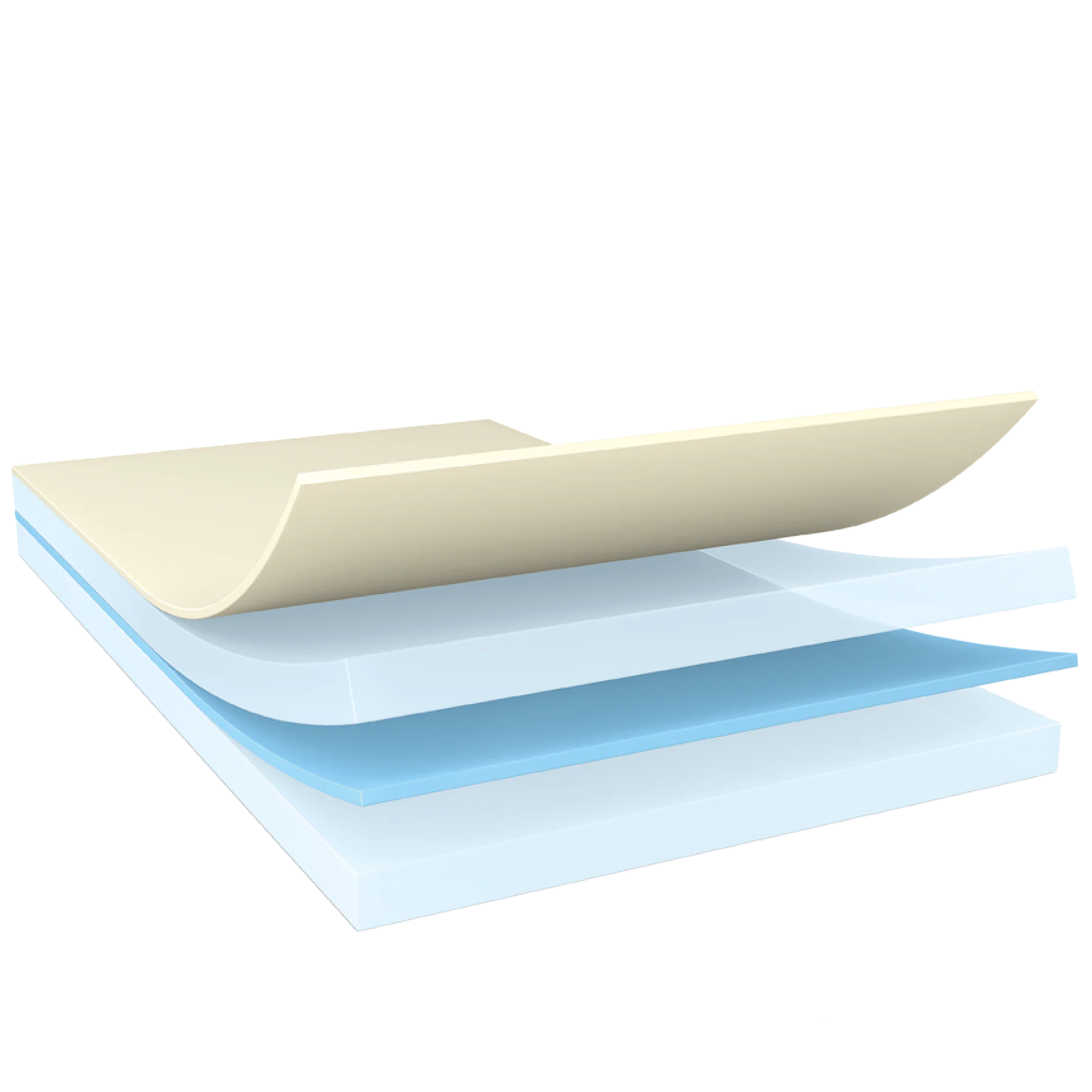

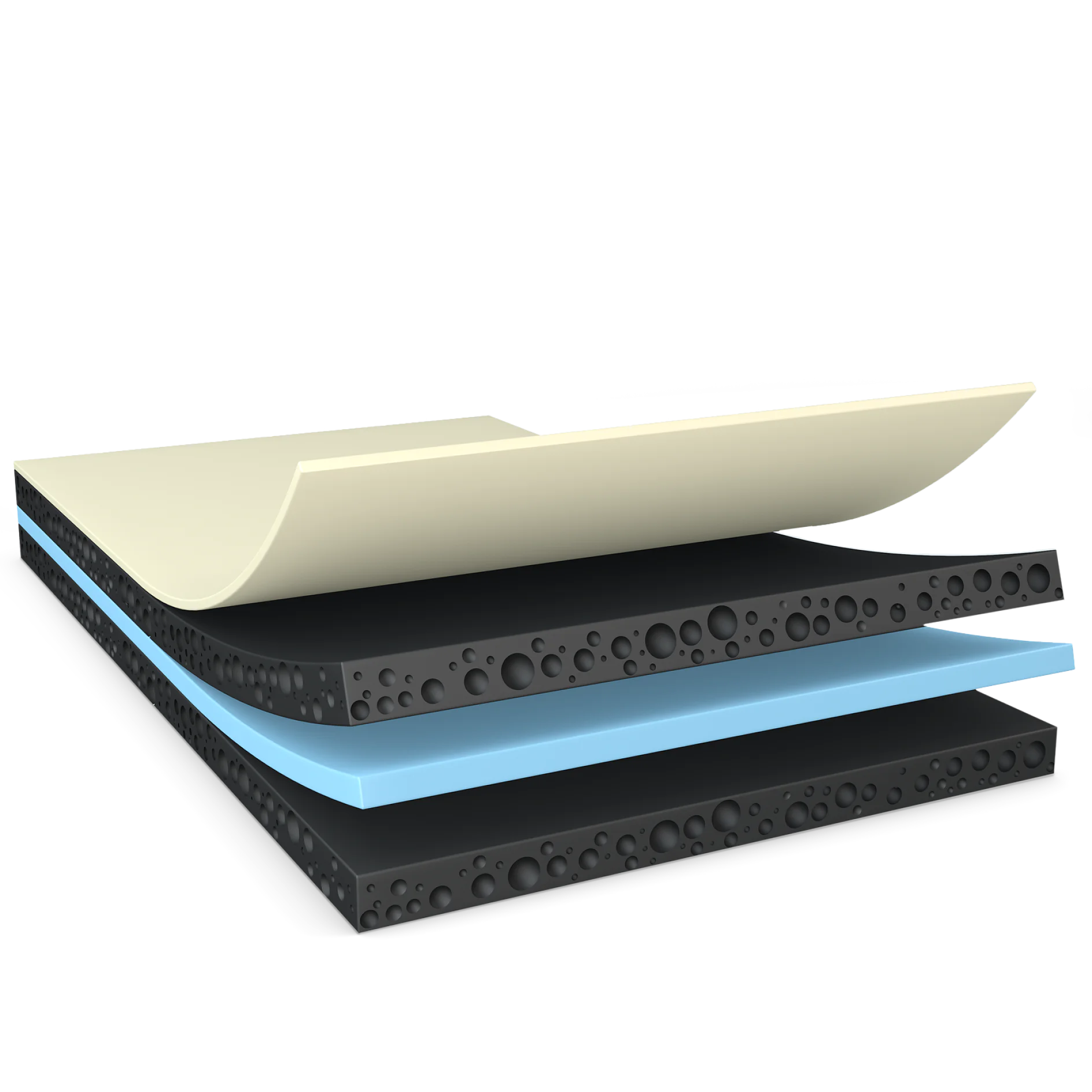

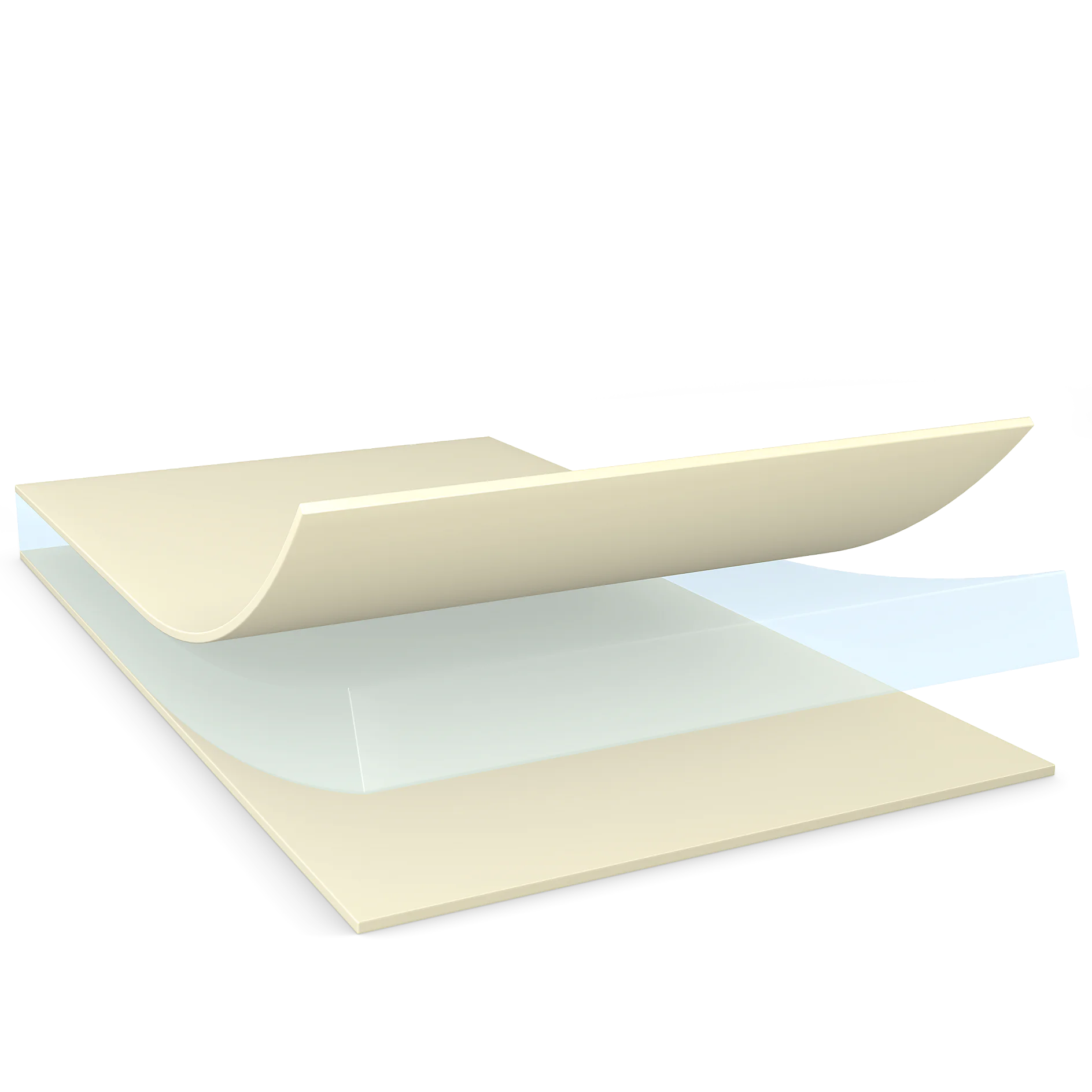

Tapes have become an essential component in the assembly of laptops. They are used to bond different parts of the device, provide laptop impact protection, and ensure components can be easily removed for repair or recycling.

Tapes are a popular adhesive choice for laptops, as they not only take up less space within a device but are significantly lighter than alternatives such as liquid glue or mechanical fastenings.

Here at tesa, we have tapes that help laptop manufacturers improve design, reliability, and robustness and meets today’s increasingly complex and demanding production and assembly processes.

![tesa_ECT_woven-gray_dr_006 [en-en] tesa_ECT_woven-gray_dr_006](/en/files/images/202409/3/tesa-ect-woven-gray-dr-006,11581574_canvas1x1_18.webp)