Tissue tapes – the smart choice for delicate protection and precision masking

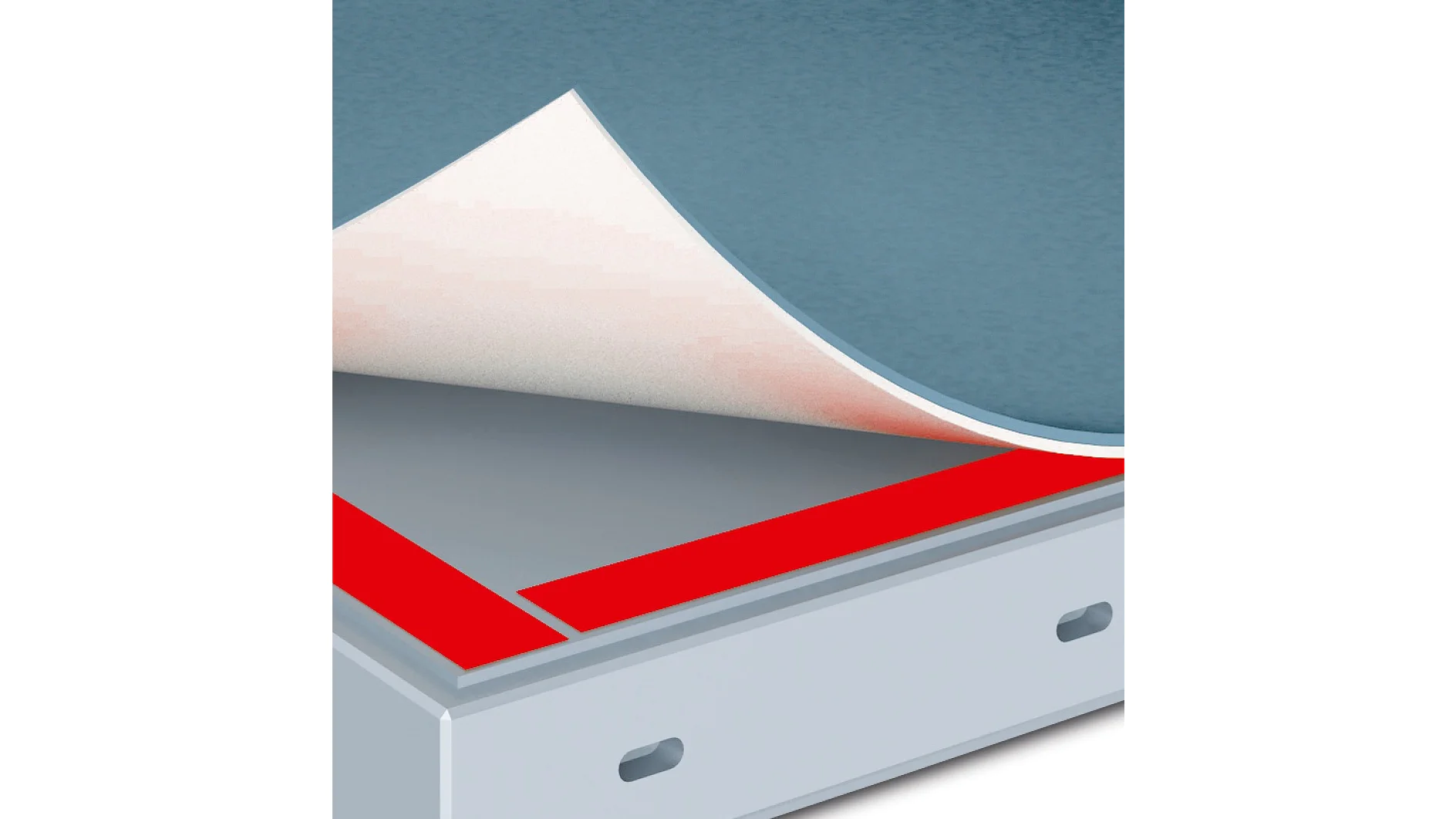

Tissue tape is a thin, fibrous adhesive tape that uses a lightweight tissue carrier coated with high-performance adhesive. Its defining strength lies in the balance between flexibility and stability: thin enough for detailed work, yet strong enough to deliver dependable results. Double sided tissue tapes combine flexibility, conformability, and strong adhesion to meet demanding industrial mounting applications. Thanks to their non-woven or cloth backings, they adapt to irregular surfaces, are hand-tearable yet tear-resistant, and can be easily die-cut for precision use. These tapes are ideal for a wide range of tasks, including lamination and splicing of foams, textiles, leather, and heavy papers, as well as floor laying and general mounting applications.

With our tissue tapes, you benefit from a product engineered not only for performance, but also for process efficiency and sustainability. Each tape is developed with attention to consistent quality, user comfort, and reduced material use — reflecting our vision of adhesive solutions that support smarter, more sustainable manufacturing.

Reliable performance in every layer

Our tissue tapes combine intelligent design with trusted adhesive expertise to deliver high-quality results across countless applications. Their lightweight tissue carrier can give them an exceptional balance of strength, flexibility, and precision — making them the ideal choice for processes that demand both reliability and finesse.

Thanks to their thin, fibrous backing, our tissue tapes can adapt smoothly to curved or textured surfaces, ensuring an even bond even where other tapes might fail. Despite being lightweight, the backing provides excellent internal strength, allowing for clean handling, die-cutting, and lamination.

Our specially formulated adhesive systems — available in acrylic, rubber, or synthetic rubber versions — ensure consistent performance on a wide range of substrates. They adhere securely during processing, yet can be removed cleanly when the job is done, leaving no residue or surface damage. For industrial users and converters, this means faster application, less rework, and a cleaner production environment.

In addition, tissue tapes are known for their excellent convertibility: they can be easily slit, cut, or shaped for precise applications, making them a go-to material for die-cut parts, splicing solutions, or detailed masking work. The low-linting tissue structure also supports clean-room manufacturing and sensitive assembly processes, where precision and cleanliness are key.

By combining high conformability, strong adhesive performance, and clean removability in a single construction, tissue tapes can offer a versatile, efficient, and sustainable choice for professionals across industries.

Where our tissue tapes deliver value

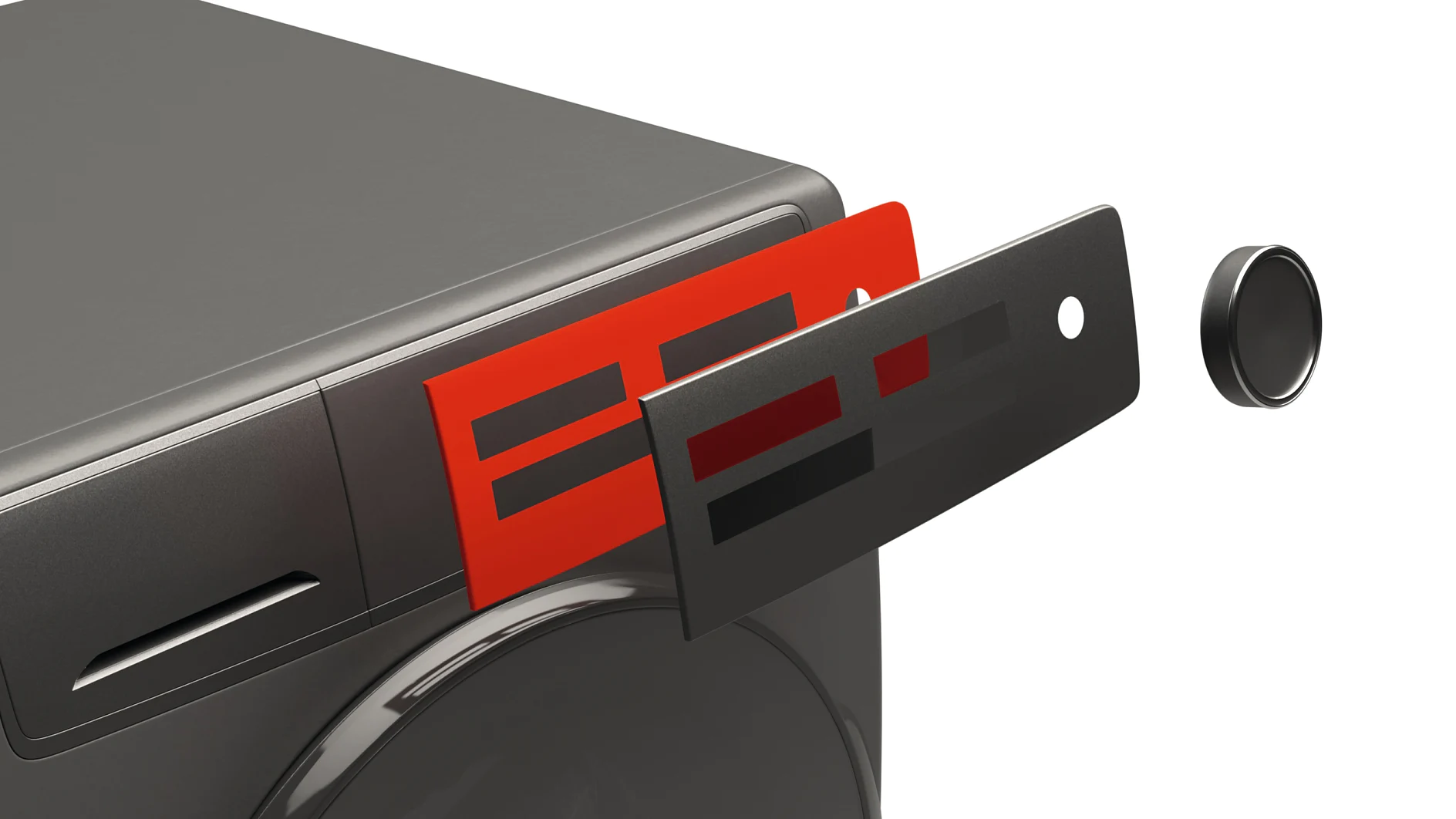

Our tissue tapes are designed to meet the high demands of professional manufacturing and assembly. Whether you’re mounting, laminating, or bonding, these solutions integrate with both manual and automated workflows across sectors such as automotive, electronics, building façades, and fashion. With our tissue tapes, you gain not just adhesive performance – but consistent product quality, process reliability, and partnership you can trust.

tesa® 8864x series double coated tissue tape at a glance

The tesa® 8864x Series Double Coated Tissue Tape was specifically developed to deliver reliable, all-around performance at a competitive price. With different adhesives matched to the tape thickness, excellent initial tack on common substrates, and easy handling, the series creates a strong bond in a single step — without residues, surface damage, or curing times required by liquid adhesives. Optimized for converting, lamination, and die-cutting, tesa® 8864x is available in 100 µm, 120 µm, 140 µm, and 160 µm thicknesses, with a translucent tape on a PE-coated paper liner.

Explore our tissue tape portfolio

Choose the right tape for your specific task. Below is a selection of common tissue-tape variants. For personalized recommendations, technical questions, or tailored formats, please

Products

FAQs

What temperature can tissue tapes handle?

Many tissue tapes, such as tesa® 60972 , offer strong temperature resistance, typically up to 80 °C for long-term exposure and up to 200°C for short-term peaks, making them suitable for a wide range of industrial mounting, laminating and finishing tasks. For applications involving extended high-temperature curing above 100 °C or exposure beyond standard cycles, we recommend consulting our technical experts to ensure the best material match for your substrates and process environment.

Can I remove the tape cleanly after a long-term application?

Yes — when choosing the correct product type. Our adhesives and tissue backings are selected to ensure minimal residue and preserved surface quality, even after extended periods.

Are more sustainable versions available?

Yes. We offer tissue tapes that support more sustainable material choices. Products within our more sustainable portfolio, such as tesa® 4959, include recycled or responsibly sourced components and reflect our broader commitment to “Rethink materials” and reducing environmental impact.

Wherever possible, we work with our customers to recommend the most sustainable option without compromising process performance.