Innovative

automotive adhesives:

driving the future

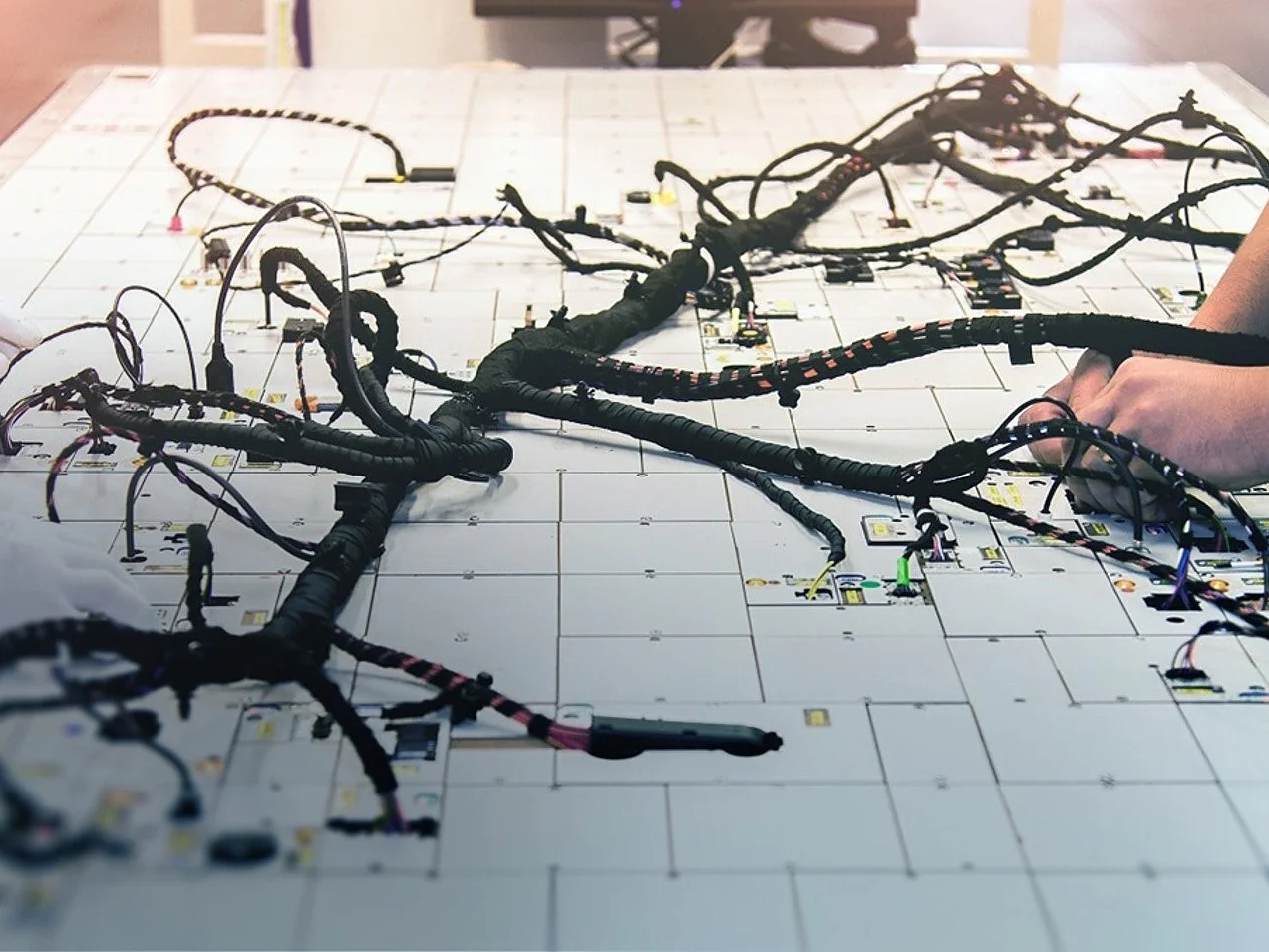

In the dynamic world of automotive manufacturing, the role of adhesives is evolving rapidly. The shift towards electric vehicles (EV) and more sophisticated human-machine interfaces (HMI) demands innovative adhesive solutions. Our range of automotive adhesives is designed to meet these challenges head-on, providing reliable and more sustainable bonding solutions for every aspect of automotive assembly.

Key application areas in the automotive industry

In the automotive industry, the right adhesive can make a significant difference in both manufacturing processes and end-product performance. Our automotive adhesives are specially formulated to meet the diverse needs of this dynamic sector. From ensuring the safety and durability of EV batteries to enhancing the aesthetics and functionality of car exteriors and interiors, our products are at the forefront of automotive innovation. Below, we delve into some of the key areas where our adhesives are making an impact.

Our portfolio of automotive adhesive solutions

Discover our adhesive solutions tailored for the automotive industry. Our advanced products ensure reliable bonding for various applications, enhancing vehicle performance and durability. Explore innovative tapes designed to meet the highest standards of quality and efficiency in automotive manufacturing and repairs.