With the development of new electronic products, the demand for adhesive solutions for fabrics and soft goods has increased considerably. The global smartwatch market, for example, grew 24 percent in 2021, due to strong demand for smartwatches under 100 dollars. The need for adhesive solutions for wristbands has increased accordingly. The active noise cancellation headphones market is forecast to grow by 14 percent for the coming years. Consequently, the demand for adhesive solutions for ear cushions is also growing. The global virtual reality headset market is even expected to increase at a rate of 28 percent – and for those devices, an adhesive solution is needed as well.

A gentle connection – tesa® LTT 874X for fabrics and soft goods

Technologies

A thermoplastic solution for soft goods

The new tesa® LTT 874X is a gentle solution for bonding wristbands, ear cushions, and virtual reality headsets as well as for keyboard covers, fabric smartphone cases, and other textiles and soft goods. Technically, tesa® LTT 874X is a low-temperature thermoplastic structural bonding film. This means it is a tape that is not yet tacky at room temperature. tesa® LTT 874X can be processed at temperatures starting at 80 °C. It is therefore ideal for heat-sensitive soft goods applications.

Unlike liquid adhesives, tesa® LTT 874X has the advantage that it does not require curing time and that spills are not possible. The adhesive remains chemically unchanged when it is applied. The softening is due to a purely physical process and therefore reversible.

Characteristics and application of tesa® LTT 874X

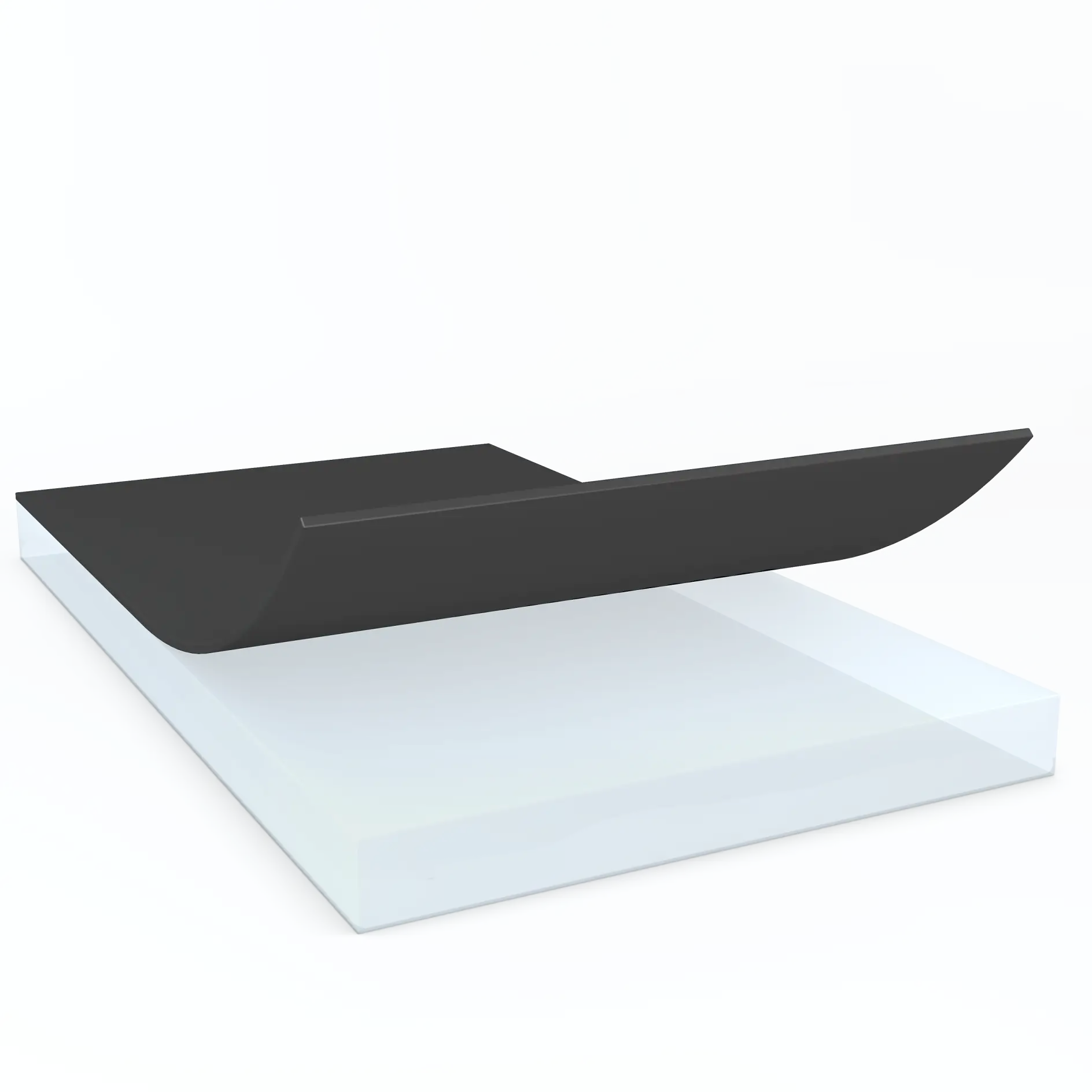

tesa® LTT 874X is a translucent transfer film. It consists of a polyethylene (PE) liner and thermoplastic polyurethane adhesive with a thickness of 30 or 50 µm. It is typically applied using a heat press, a cost-effective assembly process that produces fast, clean, and reliable bonds with heat and pressure. During the first step, pre-lamination, the film is laminated to the first substrate at a moderate temperature. During the second step, final bonding, a higher temperature is applied to achieve optimum bond strength.

tesa® LTT 874X was specially developed for soft goods applications that require low processing temperatures. The thermoplastic polyurethane exhibits low yellowing with aging and has very good bonding performance on a wide range of substrates. This includes, in particular, high peel adhesion on a variety of fabrics that are otherwise difficult to bond.

Learn More About tesa® LTT 874X

The latest addition to the range of structural adhesive films, tesa® LTT 874X offers a wide process window from 80 °C and reliable bonding performance on various substrates. If you are interested in tesa® LTT 874X, please don’t hesitate to contact us or your distributor.

Our technical experts in the Customer Solution Center have professional laminating, hot-pressing, hot-rolling, and oven equipment as well as climatic chambers for stress tests in defined cold, warm, dry, or humid environments. They can analyze the surface and heat transfer of bonded parts and test various process liners for their effect on tape performance. With this state-of-the-art equipment, they provide both on-site support and evaluation of specific applications under laboratory conditions.

A gentle bond for soft goods

tesa® LTT 874X consists of thermoplastic polyurethane that becomes tacky when heat is applied. It is ideal for the bonding of heat-sensitive soft goods such as smartwatch wristbands, headphone ear cushions, or fabric smartphone covers.