fta

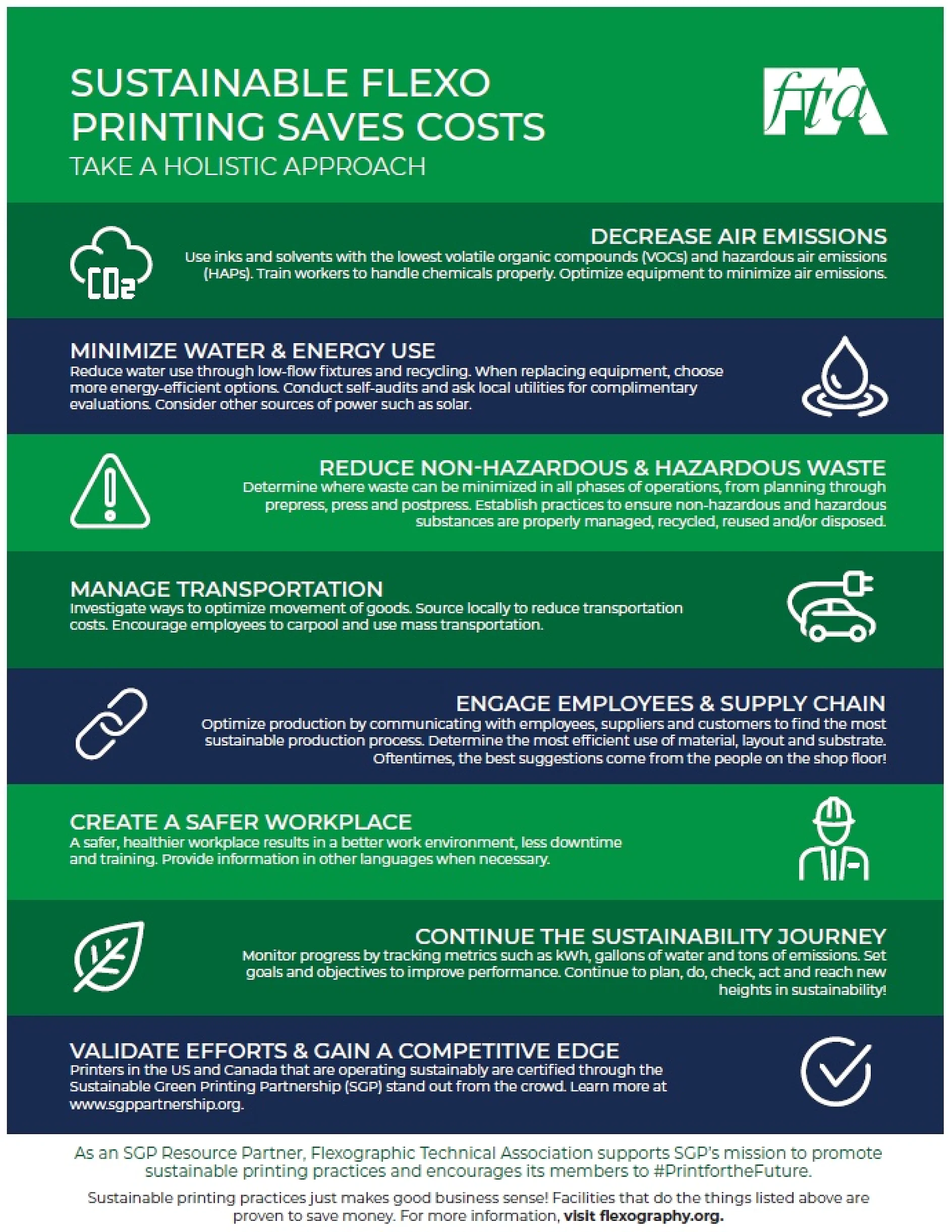

- Use inks and solvents with the lowest volatile organic compounds (VOCs) and hazardous air emissions (HAPs)

- Train workers to handle chemicals properly

- Optimize equipment to minimize air emissions

8 ม.ค. 2024

© Flexographic Technical Association

In this article we compare the key pillars of more sustainable flexographic printing identified by the Flexographic Technical Association with our own sustainability efforts here at tesa.

For us as a company in the chemical industry, pursuing a holistic and scientific approach determines our actions and is a matter of course. However, in many areas progress can only be achieved in close partnerships with suppliers and customers.

We're happy to see that our goals are so closely aligned with the priorities of the printing industry.

fta

tesa

Our mission to reduce global emissions includes upstream and downstream processes as well as our own production. Renewable energy is a key pillar of our commitment.

Our major sustainability targets 2030:

fta

tesa

At tesa, we are dedicated to minimizing water and energy consumption within our production processes. Since 2020, we have sourced 100 percent of our purchased electricity from renewable energy sources. In addition to reducing fossil-based energy consumption, increasing energy efficiency also plays an important role. To achieve this goal, we are implementing technologies that are particularly efficient in conserving resources and energy.

fta

tesa

tesa will contribute to the circular economy and use resources as carefully as possible. Where waste is unavoidable, we seek to reuse or recycle it by various means. By 2025, we want to eliminate all landfill disposal of production-related waste.

Our major sustainability targets 2030:

For flexo printers, we offer our tesa® Twinlock technology, which significantly reduces waste in plate mounting.

fta

tesa

In general, tesa's 'local for local' concept will increasingly result in shorter supply chains, targeting for production sites to be close to local markets. We have set ourselves ambitious targets for our logistic operations, with a roadmap being laid out with initial plans, and the means, routes, and modes of transport being scrutinized.

Logistics emissions contribute to our overall Scope 3 footprint as defined by the Greenhouse Gas Emissions (GHG) Protocol. Our target is to reduce these by 20% in absolute terms by 2030, compared to the 2018 baseline. An example project in the transport category involves optimum capacity utilization of containers in overseas shipping, where smart planning and digitalization play a crucial role.

Specifically for flexo printers, tesa® Twinlock helps to decrease transport emissions. When using tesa® Twinlock, you could be looking at one annual delivery instead of approximately 50 separate tape deliveries per year, which leads to fewer trucks emitting carbon dioxide.

fta

tesa

At tesa, we holistically incorporate sustainability across our supply chain. We engage with suppliers and customers to optimize production and material use and we continuously train our employees and increase the number of jobs with a focus on sustainability internally.

Our major sustainability targets 2030:

fta

tesa

Health and safety in the workplace are a key priority at tesa. For us, effective occupational health and safety measures require a systematic and consistent approach and we have set ourselves the goal of reducing the number of work accidents to zero and avoiding work-related ill health as well as physical and mental strain at work. In dedicated occupational safety commitees and in the annual management review, corporate management evaluates new steps to further improve employee safety and reduce work-related health risks. We focus on prevention and raise our employees' awareness of possible risks through initial and advanced trainings. All operating instructions are made available in local languages.

fta

tesa

We are making continuous progress when it comes to protecting the environment and climate. Environmental management systems play a key role for us here. We already use systems that are certified in accordance with an ISO 14001 matrix at all seven production facilities with a related coating unit and/or adhesive production.

We identify, assess, and monitor the progress made by our ISO 14001-certified sites in reducing their CO₂ emissions.

Our headquarters in Norderstedt and the Hamburg and Offenburg production facilities also have ISO 50001-certified energy management systems.

Every day, we keep a close eye on our targets and measure our performance against them.

fta

Printers in the US and Canada that are operating sustainably are certified through the Sustainable Green Printing Partnership (SGP) stand out from the crowd. Learn more at www.sgppartnership.org.

tesa

tesa is registered with a gold status on EcoVadis, a collaborative platform for monitoring sustainability performance. tesa is among the top 2% of companies in the industry assessed by EcoVadis.

We make all our claims on product sustainability measurable and verifiable.