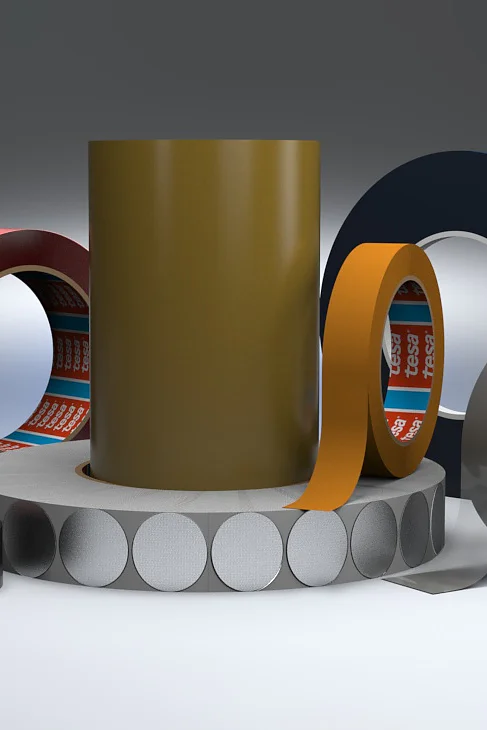

What is small and shiny and can save lives? tesa® 54332 Fireguard – our firefighter! The tape belongs to a series of special sealing solutions for the automotive industry that are used to seal holes in the vehicle body and last as long as the vehicle itself. It is important to seal holes securely because up to 220 such openings can be found in each vehicle as a result of the manufacturing process. If these holes are left open, they can cause problems ranging from corrosion to contamination and noise pollution and even dangerous overheating. tesa® 54332 Fireguard is a flame resistent sealing patch for sealing holes in the area of the traction battery.

A league of its own – tesa tape heroes