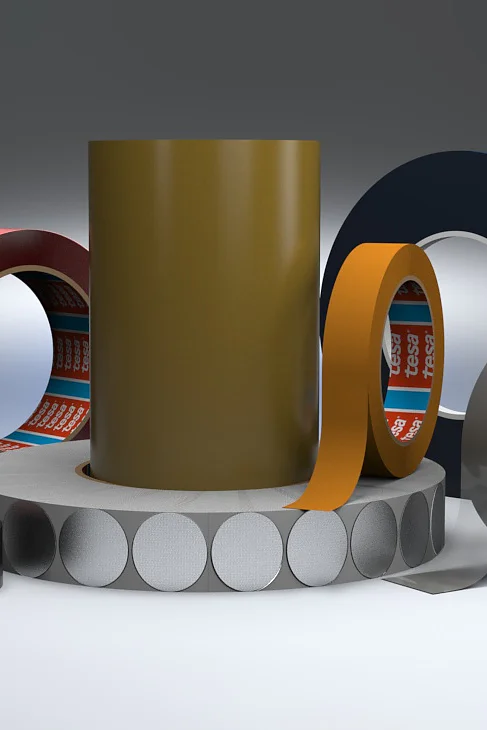

Many are probably familiar with changing reels on the fly because of movie theaters. However, this process also occurs in the printing industry, where this it is given a very significant “roll.” This is because changing from one reel of paper or film to the next should be smooth and take as little time as possible to ensure that the printing process is fast and efficient. On the one hand, the focus is on how quickly the reel can be changed. On the other, it is essential that there are absolutely no web breaks that interrupt the continuous production process. And that's exactly what the tesa® EasySplice products ensure due to their excellent splice ratios.

The introduction of the tesa® EasySplice series more than two decades ago revolutionized processes – first in the paper industry, then in the paper printing industry and later in the booming flexographic printing industry. After all, tesa® EasySplice has perfected the art of changing reels on the fly.

In the paper printing industry, tesa® EasySplice quickly became the favorite splicing tape of printers. In recent years, the range has been tailored ever more closely to the changing needs of the printing industry and, with tesa® 51948 EasySplice FilmLine Black X, this range has also made it possible to meet the high demands of the flexographic printing industry for splicing non-polar surfaces, making it the non plus ultra on the market today.