tesa® 52110 Ultra Low VOC

100 µm double sided transfer tape for lamination and converting applications

Product Features

- High initial tack and peel adhesion

- Very good bonding strength to a wide variety of substrates

- Good die-cutting properties

Product description

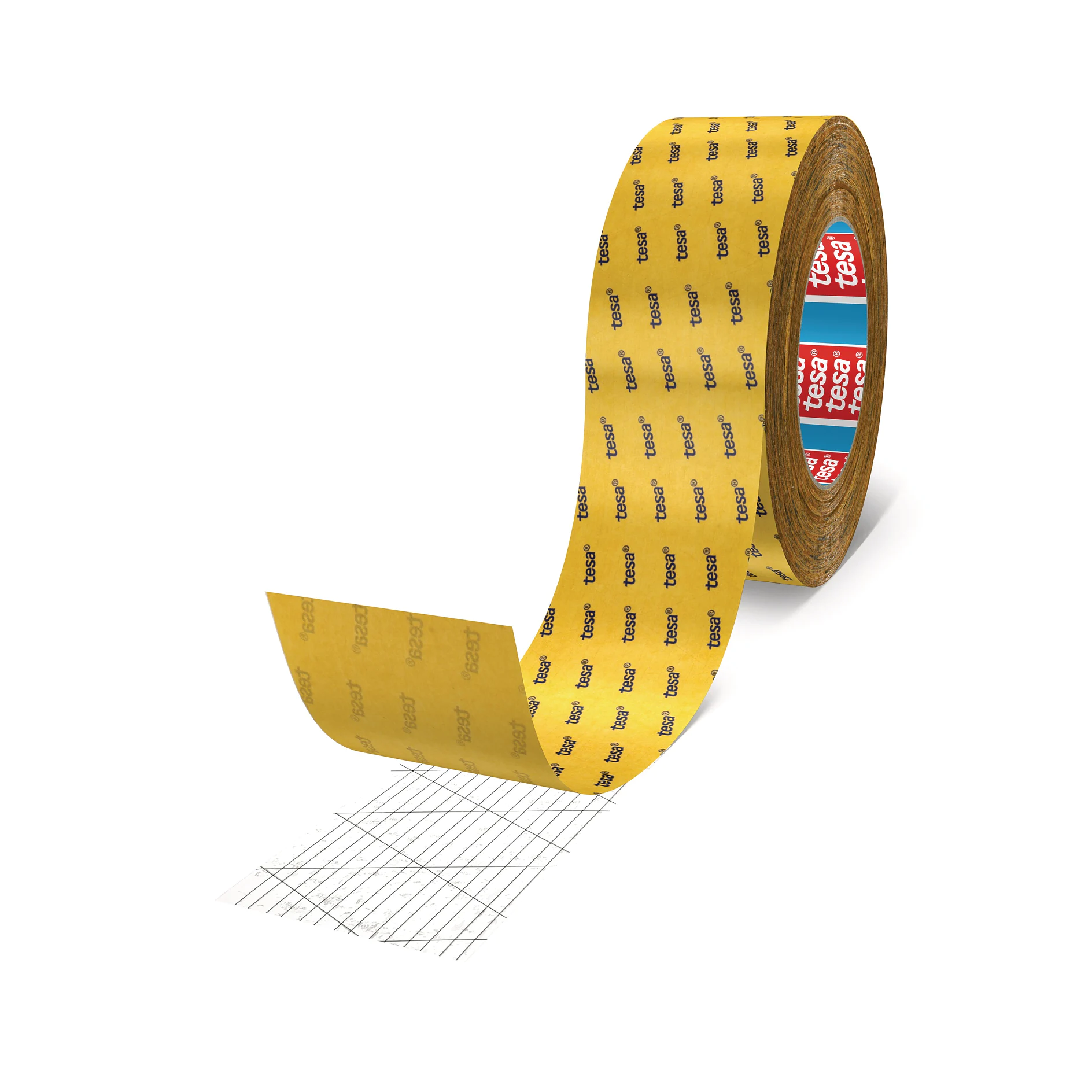

tesa® 52110 is a conformable transfer tape, equipped with a water-based acrylic adhesive and a thickness of 100 µm. The water-based acrylic adhesive is temperature resistant up to 180°C and offers very good bonding strength on various substrates. tesa® 52110 was specifically developed for all kinds of lamination and converting applications. Due to its low emission values, it is classified as ultra low VOC and particularly suited to meet interior requirements, e.g. in the automotive industry.

tesa® 52110 is available in efficient laminating lengths and widths as well as in a 50 µm version (tesa® 52105).

Product details and specifications

Product Features

- High initial tack and peel adhesion

- Very good bonding strength to a wide variety of substrates

- Good die-cutting properties

- Highly conformable to follow difficult 3D shapes

- Ultra low total VOC concentration according to VDA 278 analysis

Application Fields

Key applications include:

- Lamination of insulation materials

- Mounting of flooring systems

- Lamination of foam for HVAC (heating, ventilation, and air conditioning) seals

- Bonding of fleece and felt substrates as well as decorative fabrics

- Laminates for NVH (noise, vibration, and harshness) and BSR (buzz, squeak, and rattle) prevention

Product Construction

| Backing material | none |

|---|---|

| Colour | transparent |

| Colour of liner | yellow |

| Thickness of liner | 80 µm |

| Thickness of tape | 100 µm |

| Type of adhesive | water-based acrylic |

| Type of liner | glassine |

Product Construction

| Backing material | none |

|---|---|

| Colour | transparent |

| Colour of liner | yellow |

| Thickness of liner | 80 µm |

| Thickness of tape | 100 µm |

| Type of adhesive | water-based acrylic |

| Type of liner | glassine |

Properties / Performance Values

| Temperature resistance short term duration | 100 °C |

|---|---|

| Humidity resistance | good |

| Ageing resistance (UV) | very good |

| Suitable for rough surfaces | very good |

| Fogging | very good |

| Temperature resistance max | 180 °C |

Properties / Performance Values

| Temperature resistance short term duration | 100 °C |

|---|---|

| Humidity resistance | good |

| Ageing resistance (UV) | very good |

| Suitable for rough surfaces | very good |

| Fogging | very good |

| Temperature resistance max | 180 °C |

Adhesion to Values

| Adhesion to ABS (initial) | 6 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) | 9 N/cm |

| Adhesion to PP (initial) | 5.1 N/cm |

| Adhesion to PP (after 14 days) | 6.8 N/cm |

| Adhesion to Steel (initial) | 9.2 N/cm |

| Adhesion to Steel (after 14 days) | 11.6 N/cm |

Adhesion to Values

| Adhesion to ABS (initial) | 6 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) | 9 N/cm |

| Adhesion to PP (initial) | 5.1 N/cm |

| Adhesion to PP (after 14 days) | 6.8 N/cm |

| Adhesion to Steel (initial) | 9.2 N/cm |

| Adhesion to Steel (after 14 days) | 11.6 N/cm |

Download the files below for more technical details and information on this product.