tesa® 51014

215 μm double sided translucent non woven tape with asymmetrical product design

Product Features

- Asymmetrical product design with 150 µm adhesive on liner-covered side, 50 µm on open side

- Excellent performance on rough surfaces like leather and textiles

- High initial tack and peel adhesion

Product description

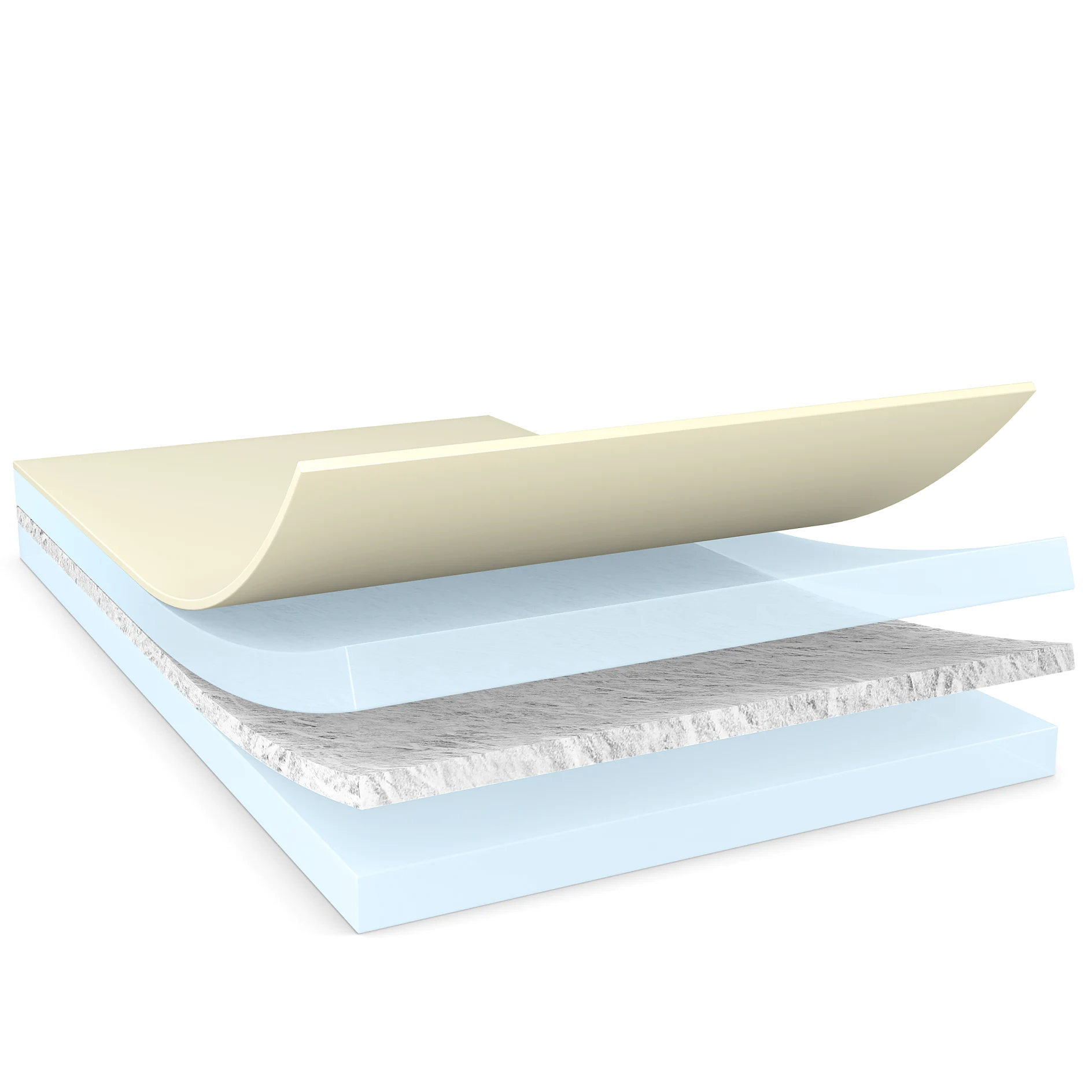

tesa® 51014 is a double-sided industrial mounting tape consisting of a non-woven backing and a highly tackified acrylic adhesive. The asymmetrical non-woven tape is especially designed for excellent performance on rough surfaces like leather and textiles, or plaster and stone. The liner-covered side of tesa® 51014 has a high coating weight for maximum flexibility and versatility for multiple surface demands, particularly very rough surfaces. The open side has a reduced coating weight that delivers a secure bond to flat surfaces under controlled conditions. The mounting tape is able to withstand numerous environmental factors such as humidity, UV light, and temperatures of up to 200°C for limited periods of time. The tackified acrylic adhesive offers excellent hold on various surfaces, very high tack, and good shear strength. The adhesive is coated on a flexible and conformable cellulose non-woven backing that even conforms to difficult 3D shapes.

Product details and specifications

Product Features

- Asymmetrical product design with 150 µm adhesive on liner-covered side, 50 µm on open side

- Excellent performance on rough surfaces like leather and textiles

- High initial tack and peel adhesion

- Immediate usability right after assembly

- Reliable bond, often also on low surface energy surfaces

Application Fields

- tesa® 51014 is suitable for various types of mounting applications

- Bonding leather and textiles as sewing support

- Laminating foamed materials in combination with smooth materials on the open side

- Mounting car roof linings in car production

- Mounting cables and wire harnesses to headliners for automotive interiors

Product Construction

| Adhesive Type | tackified acrylic |

|---|---|

| Backing material | non-woven |

| Color | translucent |

| Color of liner | red |

| Liner Type | PE |

| Thickness of liner | 90 µm |

| Total thickness | 215 µm |

| Weight of liner | 82 g/m² |

Product Construction

| Adhesive Type | tackified acrylic |

|---|---|

| Backing material | non-woven |

| Color | translucent |

| Color of liner | red |

| Liner Type | PE |

| Thickness of liner | 90 µm |

| Total thickness | 215 µm |

| Weight of liner | 82 g/m² |

Properties / Performance Values

| Elongation at break | 3 % |

|---|---|

| Tensile strength | 8 N/cm |

| Temperature resistance long term | 80 °C |

| Temperature resistance short term | 200 °C |

| Temperature resistance min. | -40 °C |

Properties / Performance Values

| Elongation at break | 3 % |

|---|---|

| Tensile strength | 8 N/cm |

| Temperature resistance long term | 80 °C |

| Temperature resistance short term | 200 °C |

| Temperature resistance min. | -40 °C |

Adhesion to Values

| Adhesion to ABS (initial) | 6.5 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) | 7.6 N/cm |

| Adhesion to ABS (covered side, after 14 days) | 13.1 N/cm |

| Adhesion to ABS (covered side, initial) | 11.3 N/cm |

| Adhesion to Aluminium (initial) | 5.9 N/cm |

| Adhesion to Aluminium (after 14 days) | 6.3 N/cm |

| Adhesion to Aluminium (covered side, after 14 days) | 12.1 N/cm |

| Adhesion to Aluminium (covered side, initial) | 10.8 N/cm |

| Adhesion to PC (initial) | 6.8 N/cm |

| Adhesion to PC (after 14 days) | 12.9 N/cm |

| Adhesion to PC (covered side, after 14 days) | 16 N/cm |

| Adhesion to PC (covered side, initial) | 12.8 N/cm |

| Adhesion to PE (initial) | 5.2 N/cm |

| Adhesion to PE (after 14 days) | 5.6 N/cm |

| Adhesion to PE (covered side, initial) | 7.5 N/cm |

| Adhesion to PE (covered side, after 14 days) | 8.6 N/cm |

| Adhesion to PET (initial) | 5.5 N/cm |

| Adhesion to PET (after 14 days) | 5.9 N/cm |

| Adhesion to PET (covered side, initial) | 10 N/cm |

| Adhesion to PET (covered side, after 14 days) | 11.8 N/cm |

| Adhesion to PP (initial) | 5.2 N/cm |

| Adhesion to PP (after 14 days) | 5.8 N/cm |

| Adhesion to PP (covered side, after 14 days) | 13.3 N/cm |

| Adhesion to PP (covered side, initial) | 10.6 N/cm |

| Adhesion to PS (initial) | 6.6 N/cm |

| Adhesion to PS (after 14 days) | 7.5 N/cm |

| Adhesion to PS (covered side, after 14 days) | 12.9 N/cm |

| Adhesion to PS (covered side, initial) | 12.1 N/cm |

| Adhesion to PVC (initial) | 5.9 N/cm |

| Adhesion to PVC (after 14 days) | 9.5 N/cm |

| Adhesion to PVC (covered side, initial) | 8.8 N/cm |

| Adhesion to PVC (covered side, after 14 days) | 13.8 N/cm |

| Adhesion to Steel (initial) | 7.3 N/cm |

| Adhesion to Steel (after 14 days) | 8.6 N/cm |

| Adhesion to Steel (covered side, after 14 days) | 12.9 N/cm |

| Adhesion to Steel (covered side, initial) | 11.7 N/cm |

Adhesion to Values

| Adhesion to ABS (initial) | 6.5 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) | 7.6 N/cm |

| Adhesion to ABS (covered side, after 14 days) | 13.1 N/cm |

| Adhesion to ABS (covered side, initial) | 11.3 N/cm |

| Adhesion to Aluminium (initial) | 5.9 N/cm |

| Adhesion to Aluminium (after 14 days) | 6.3 N/cm |

| Adhesion to Aluminium (covered side, after 14 days) | 12.1 N/cm |

| Adhesion to Aluminium (covered side, initial) | 10.8 N/cm |

| Adhesion to PC (initial) | 6.8 N/cm |

| Adhesion to PC (after 14 days) | 12.9 N/cm |

| Adhesion to PC (covered side, after 14 days) | 16 N/cm |

| Adhesion to PC (covered side, initial) | 12.8 N/cm |

| Adhesion to PE (initial) | 5.2 N/cm |

| Adhesion to PE (after 14 days) | 5.6 N/cm |

| Adhesion to PE (covered side, initial) | 7.5 N/cm |

| Adhesion to PE (covered side, after 14 days) | 8.6 N/cm |

| Adhesion to PET (initial) | 5.5 N/cm |

| Adhesion to PET (after 14 days) | 5.9 N/cm |

| Adhesion to PET (covered side, initial) | 10 N/cm |

| Adhesion to PET (covered side, after 14 days) | 11.8 N/cm |

| Adhesion to PP (initial) | 5.2 N/cm |

| Adhesion to PP (after 14 days) | 5.8 N/cm |

| Adhesion to PP (covered side, after 14 days) | 13.3 N/cm |

| Adhesion to PP (covered side, initial) | 10.6 N/cm |

| Adhesion to PS (initial) | 6.6 N/cm |

| Adhesion to PS (after 14 days) | 7.5 N/cm |

| Adhesion to PS (covered side, after 14 days) | 12.9 N/cm |

| Adhesion to PS (covered side, initial) | 12.1 N/cm |

| Adhesion to PVC (initial) | 5.9 N/cm |

| Adhesion to PVC (after 14 days) | 9.5 N/cm |

| Adhesion to PVC (covered side, initial) | 8.8 N/cm |

| Adhesion to PVC (covered side, after 14 days) | 13.8 N/cm |

| Adhesion to Steel (initial) | 7.3 N/cm |

| Adhesion to Steel (after 14 days) | 8.6 N/cm |

| Adhesion to Steel (covered side, after 14 days) | 12.9 N/cm |

| Adhesion to Steel (covered side, initial) | 11.7 N/cm |

Download the files below for more technical details and information on this product.