The tesacohesion team introduced the customer to the tesa® ACXplus range and proposed tesa® ACXplus 7065 (opens in a new window or tab) as the best tape for optimising the bonding process after completion of the powder-coating process.

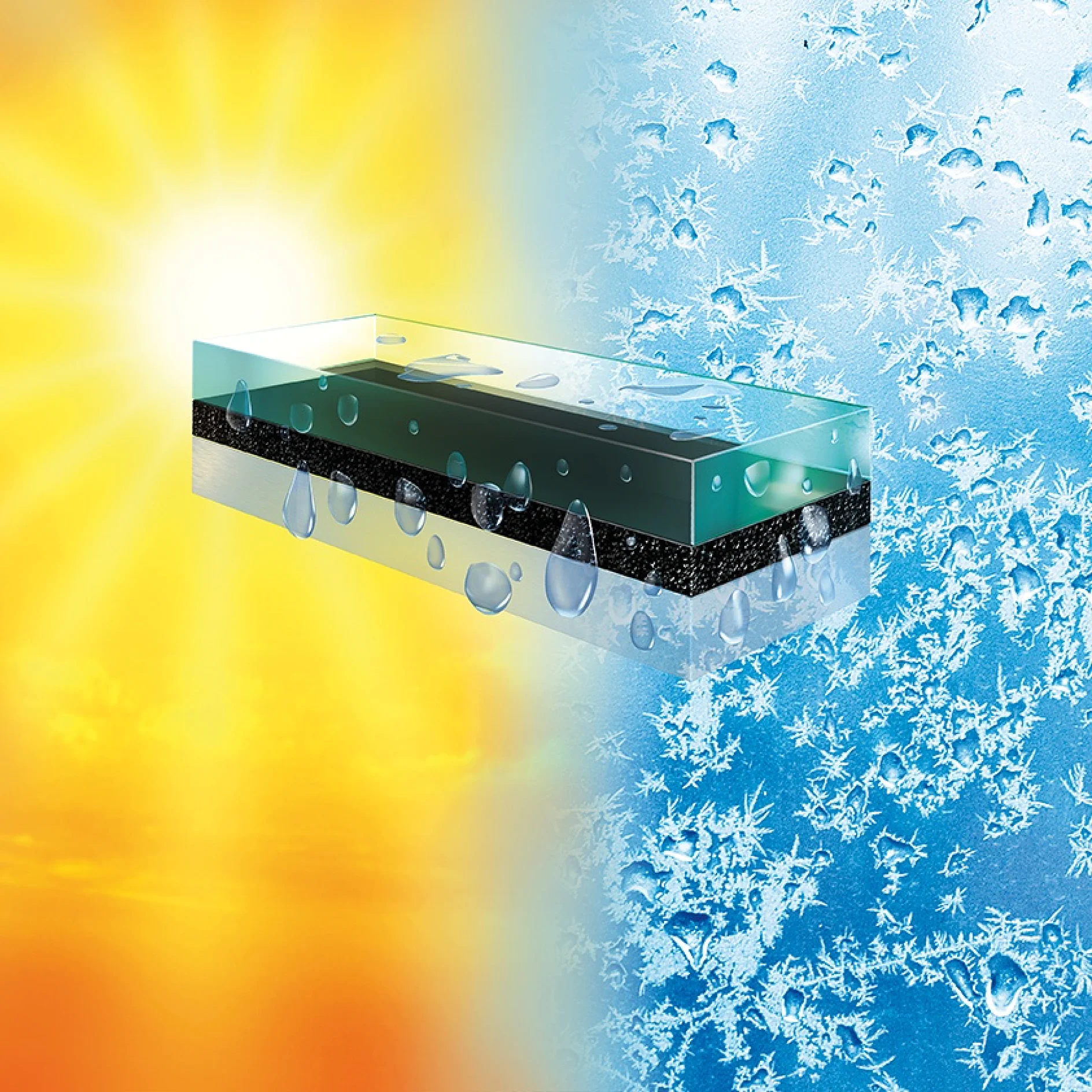

tesa® ACXplus is based on high capacity acrylates which facilitate long term, constructive bonding on both indoor and outdoor applications.

By comparison to traditional bonding methods, this offers many advantages including clear full-surface bonding, extreme load capacity, stress dissipation, corrosion prevention and resistance to weather and temperature.

Specially balanced elastic and viscous properties within the tape dissipate extreme physical stress in compensating for different rates of thermal expansion and contraction of different substrates.

Where enclosures or cabinets are fitted with dissimilar substrates and used in harsh environments, tesa® ACXplus delivers a high strength bond, even where extreme temperatures or uneven surfaces are encountered.