Additional Info

Technical recommendations:

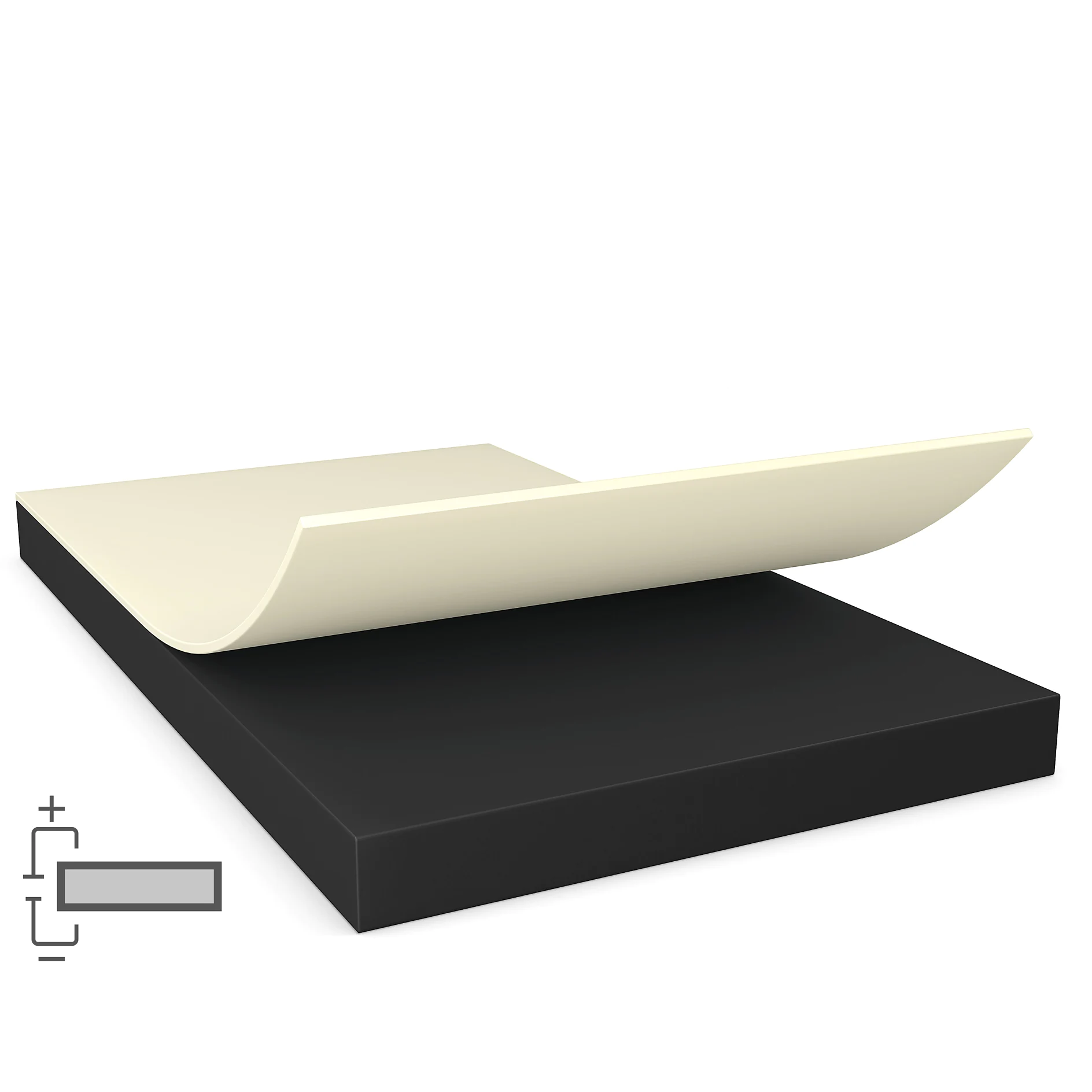

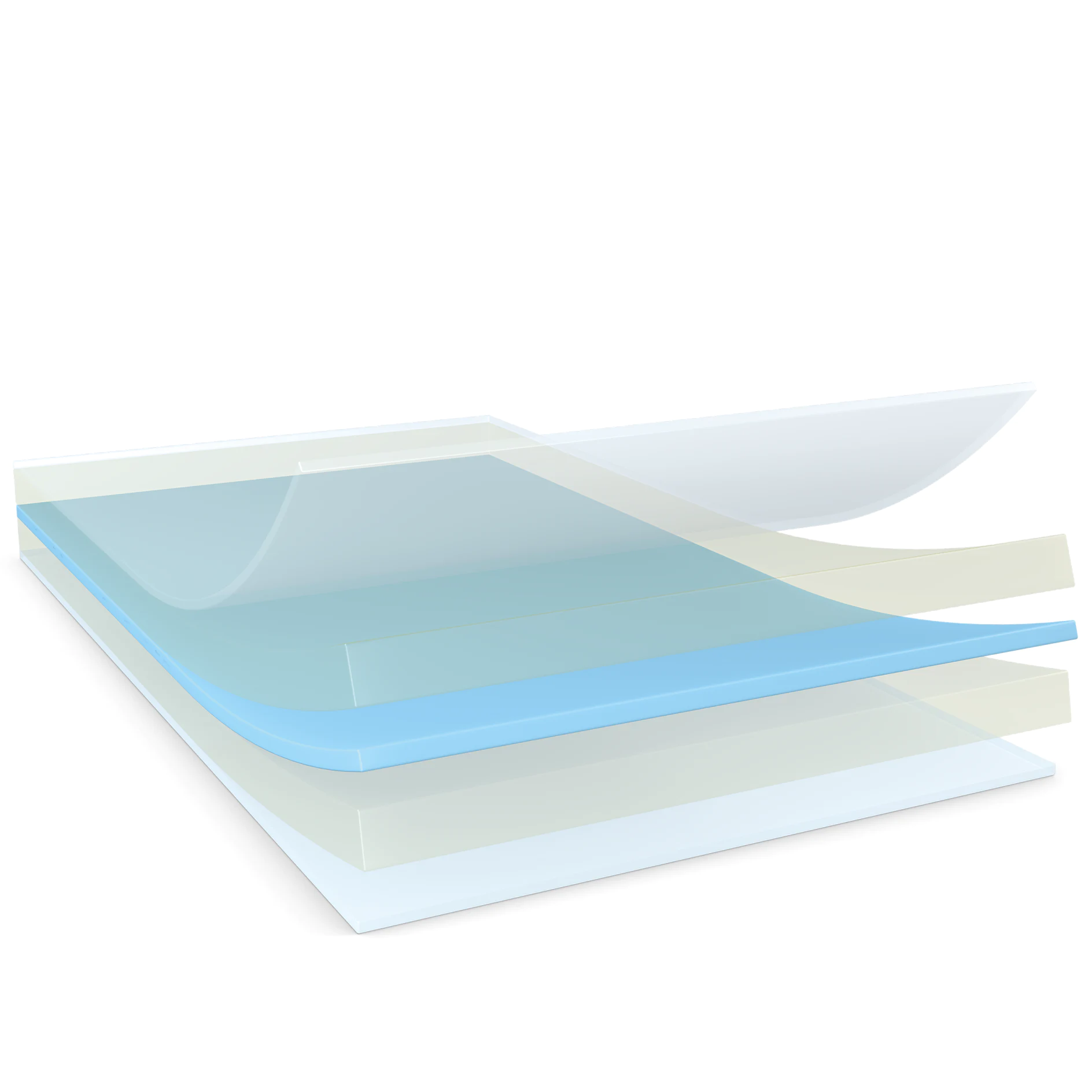

tesa® LTR 8711 is not self adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

1. Pre-lamination:

During pre-lamination, laminate the adhesive tape onto the first component.

Setting:

2. Bonding:

Remove the liner from tape after the pre-lamination step.

Position the second component. Apply temperature and pressure for the bonding time to reach sufficient bonding strength.

Setting:

To reach maximum bonding strength, surfaces should be clean and dry. Allow at least 1-2 hours dwell-time after bonding before performance testing. Final bonding strength will be reached after 24 hours.

Bonding strength values were obtained under standard laboratory conditions (Material: PC/PC; bonding conditions: temperature (jig) = 90 °C; pressure = 5 bar; time = 120 sec).

Storage:

tesa recommends storage in original packaging in cool and dry conditions.

Low Temperature Reactive should not be exposed to more than 35°C before bonding (during transport, storage and converting).

The shelf life is 15 months after coating date. For the actual shelf life please refer to the best before date on the label in the log roll core.

¹ ‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line.

² ‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transferred from jig surface directly to the bonding area.

tesa® LTR 8711 is not self adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

1. Pre-lamination:

During pre-lamination, laminate the adhesive tape onto the first component.

Setting:

- Temperature¹: 50–60 °C

- Pressure²: 1–3 bar

- Time: 5–20 s

2. Bonding:

Remove the liner from tape after the pre-lamination step.

Position the second component. Apply temperature and pressure for the bonding time to reach sufficient bonding strength.

Setting:

- Temperature¹: 75–110 °C

- Pressure²: 2–4 bar

- Time: 10–480 s

To reach maximum bonding strength, surfaces should be clean and dry. Allow at least 1-2 hours dwell-time after bonding before performance testing. Final bonding strength will be reached after 24 hours.

Bonding strength values were obtained under standard laboratory conditions (Material: PC/PC; bonding conditions: temperature (jig) = 90 °C; pressure = 5 bar; time = 120 sec).

Storage:

tesa recommends storage in original packaging in cool and dry conditions.

Low Temperature Reactive should not be exposed to more than 35°C before bonding (during transport, storage and converting).

The shelf life is 15 months after coating date. For the actual shelf life please refer to the best before date on the label in the log roll core.

¹ ‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line.

² ‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transferred from jig surface directly to the bonding area.

![tesa_HAF-amber_dr_001 [en-en] tesa_HAF-amber_dr_001](/en/files/images/202402/2/medium-11173882,11173882_padded1x1_18.webp)