Additional Info

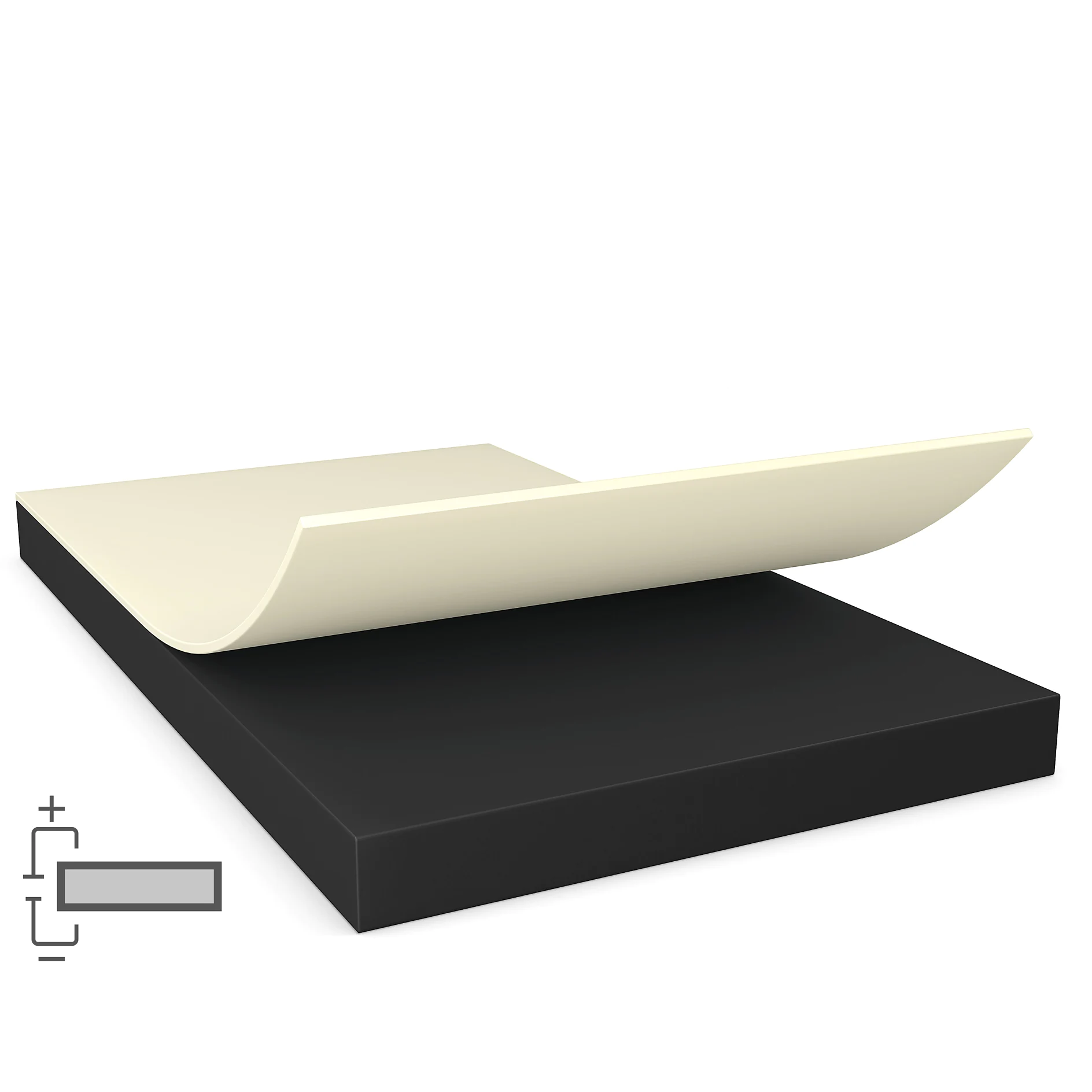

Bonding of opaque substrates

The open time of tesa® L-tape enables the bonding of opaque substrates like plastics and metals. tesa® L-tape can be activated by UV or blue light before or after bonding to the first substrate.

Activation before bonding: The die-cut of tesa® L-tape is activated by UV or blue light. The covering liner of the die-cut must be light-permeable (e.g., clear PET) to enable the activation of the tape. After activation the die-cut is bonded onto the first substrate. The second substrate is then bonded within 10 minutes by applying pressure (≥ 3 bar).

Activation after bonding to the first substrate: The die-cut of tesa® L-tape is bonded onto the first substrate. After activation by UV or blue light, the second substrate is bonded within 10 minutes by applying pressure (≥ 3 bar).

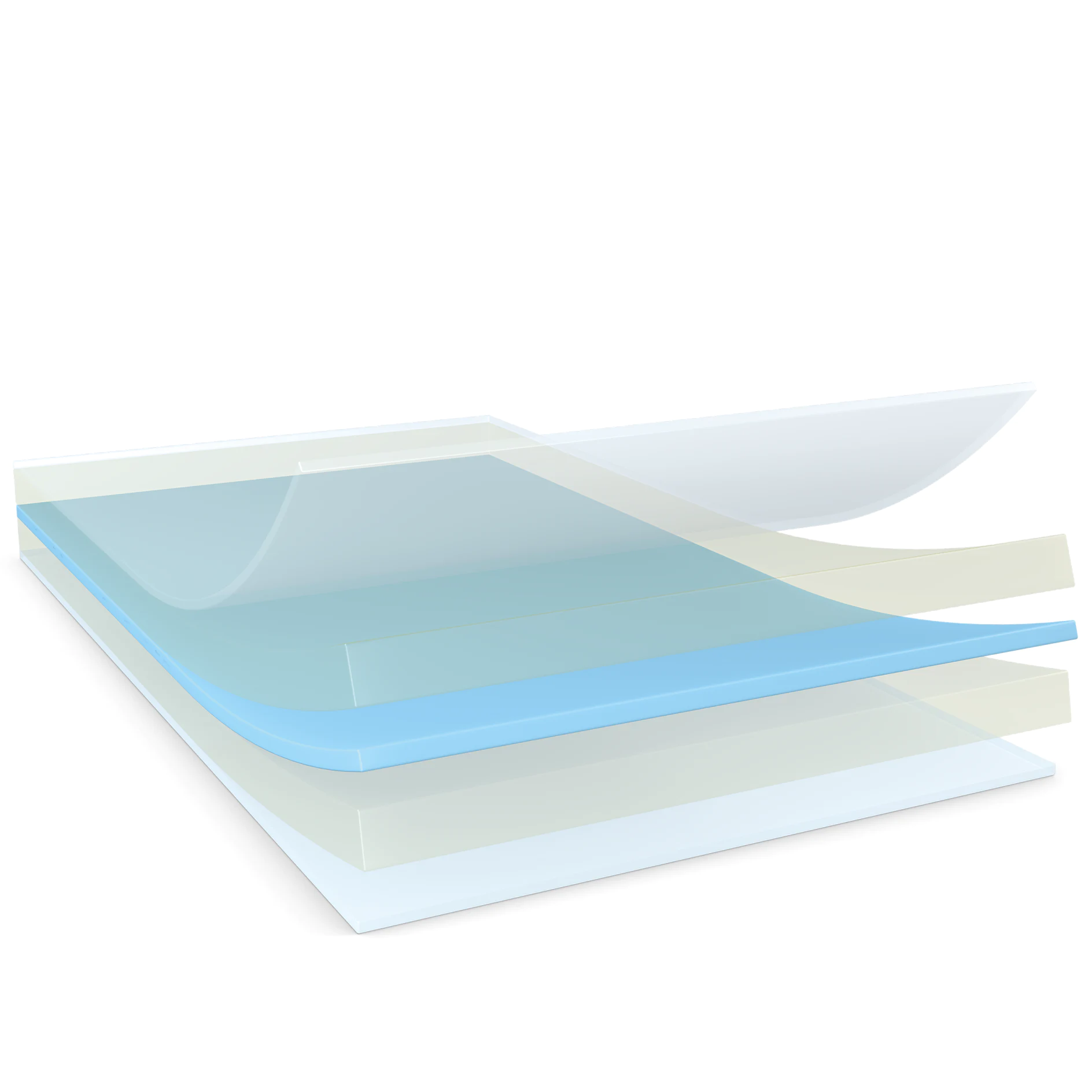

Bonding of translucent substrates

Translucent substrates such as clear plastics can be bonded before activation by UV or blue light. At least one substrate must be light-permeable to allow the activation of tesa® L-tape. After applying tesa® L-tape to the first substrate, the second substrate is bonded by applying pressure (≥ 3 bar). The bonded parts are then exposed to UV or blue light to start the curing of the adhesive.

Pre-lamination conditions

- Before curing, tesa® L-tape has initial tack and can be applied like a common PSA tape

- A pressure of ≥ 1 bar should be applied to ensure proper wet-out to the surface

- Light source: lamp of 460 nm

- Light dose: 30-50 J/cm² at 460 nm

- Recommended pressure: ≥ 3 bar

- Recommended bonding time: ≥ 10 s

tesa® L-tape can also be activated by UV Light with wavelength of 365nm:

- Light source: lamp of 365 nm

- Light dose: 15-30 J/cm² at 365 nm

- Recommended pressure: ≥ 3 bar

- Recommended bonding time: ≥ 10 s

This can result in:

- Loss of tack

- Poor bonding

- In more extreme cases, surface damage

![tesa_HAF-amber_dr_001 [en-en] tesa_HAF-amber_dr_001](/en/files/images/202402/2/medium-11173882,11173882_padded1x1_18.webp)