Additional Info

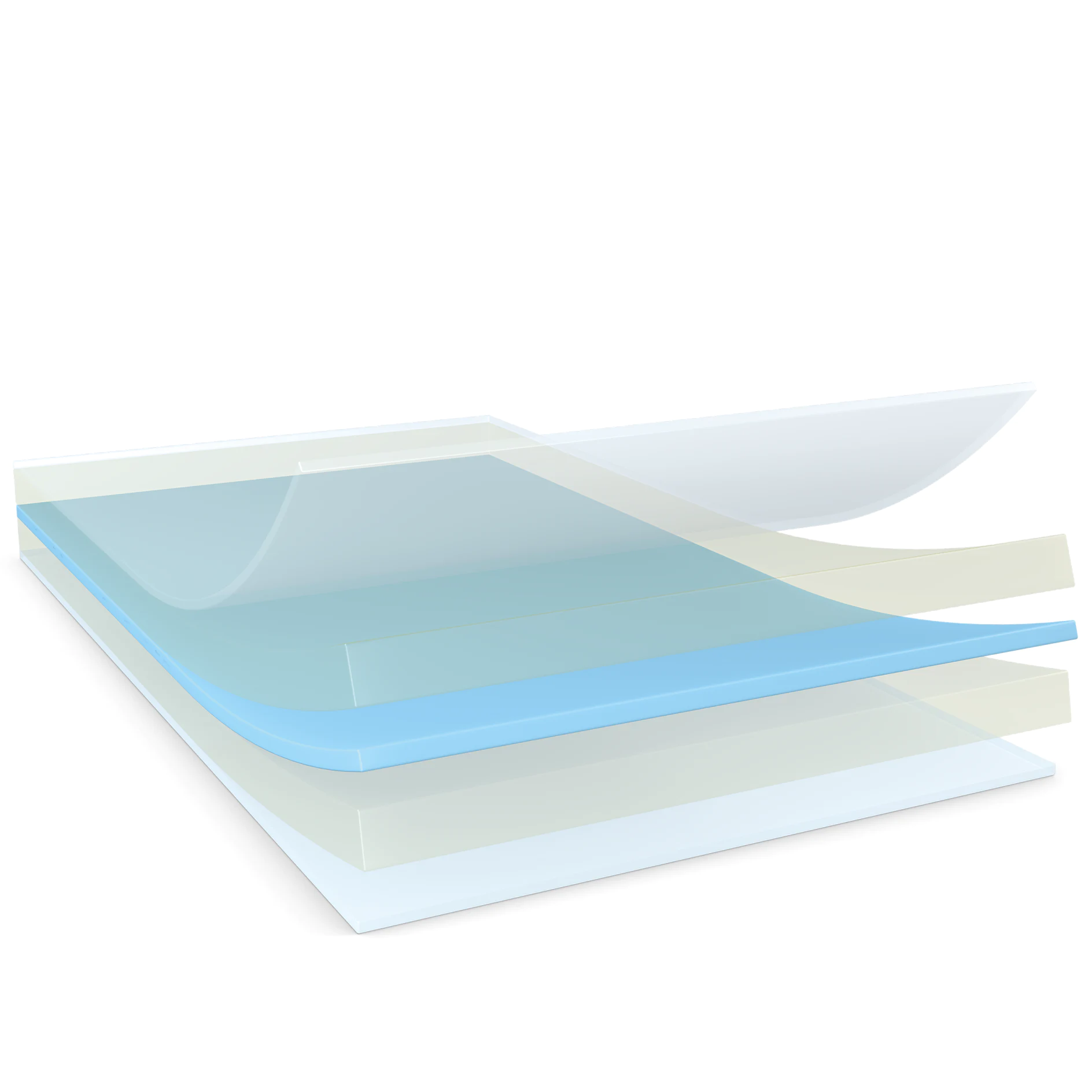

Technical recommendations: tesa HAF® 58451 is not self adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

1. Pre-lamination: During pre-lamination, the tape is laminated onto one component.

Setting:

2. Bonding: Remove the liner from the tape after pre-lamination step. Place the pre-laminated component onto the substrate to bond with. Apply sufficient temperature while applying pressure for the bonding time to reach sufficient bonding strength.

Setting:

¹ ‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line. ² ‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transformed from jig surface directly to the bonding area. Bonding strength values were obtained under standard laboratory conditions. (Material: SUS test specimen / bonding conditions: temperature = 180 °C; pressure = 30 bar; time = 30 sec). To reach maximum bonding strength surfaces should be clean and dry.

1. Pre-lamination: During pre-lamination, the tape is laminated onto one component.

Setting:

- Temperature¹: ≥120 °C

- Pressure²: ≥5 bar

- Time: 5-10 s

2. Bonding: Remove the liner from the tape after pre-lamination step. Place the pre-laminated component onto the substrate to bond with. Apply sufficient temperature while applying pressure for the bonding time to reach sufficient bonding strength.

Setting:

- Temperature¹: 120-250 °C

- Pressure²: 5-30 bar

- Time: 5 s – 3 min

¹ ‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line. ² ‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transformed from jig surface directly to the bonding area. Bonding strength values were obtained under standard laboratory conditions. (Material: SUS test specimen / bonding conditions: temperature = 180 °C; pressure = 30 bar; time = 30 sec). To reach maximum bonding strength surfaces should be clean and dry.

![tesa_HAF-amber_dr_001 [en-en] tesa_HAF-amber_dr_001](/en/files/images/202402/2/medium-11173882,11173882_padded1x1_18.webp)