Additional Info

Processing:

1. Pre-lamination:

tesa HAF® 8490 is laminated before curing. For this process we recommend a temperature between 120 °C and 140 °C.

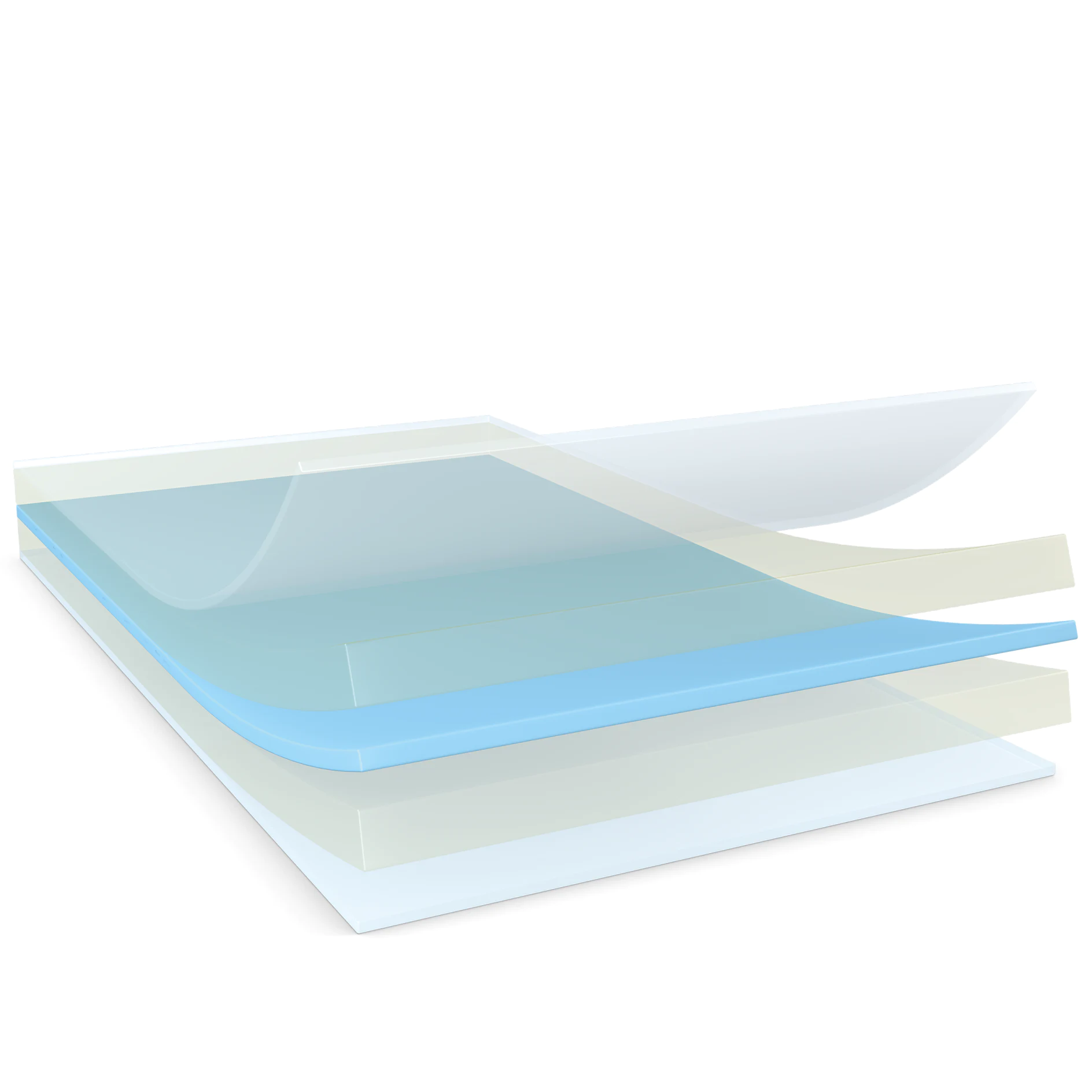

2. Bonding:

The bonding conditions temperature, pressure and time depend on the application. Following parameters can be regarded as a guideline:

Splicing application:

Bonding strength values were obtained under standard laboratory conditions. Value is guaranteed clearance limit checked with each production batch (Material: Etched aluminium test specimen / Bonding conditions: temperature = 120 °C; pressure = 10 bar; time = 8 min).

To reach maximum bonding strength surfaces should be clean and dry. Storage conditions according to tesa HAF® shelf life concept.

1. Pre-lamination:

tesa HAF® 8490 is laminated before curing. For this process we recommend a temperature between 120 °C and 140 °C.

2. Bonding:

The bonding conditions temperature, pressure and time depend on the application. Following parameters can be regarded as a guideline:

Splicing application:

- Temperature: 120–220 °C

- Pressure: > 2 bar

- Time: 15–90 s.

Bonding strength values were obtained under standard laboratory conditions. Value is guaranteed clearance limit checked with each production batch (Material: Etched aluminium test specimen / Bonding conditions: temperature = 120 °C; pressure = 10 bar; time = 8 min).

To reach maximum bonding strength surfaces should be clean and dry. Storage conditions according to tesa HAF® shelf life concept.

![tesa_HAF-amber_dr_001 [en-en] tesa_HAF-amber_dr_001](/en/files/images/202402/2/medium-11173882,11173882_padded1x1_18.webp)