Additional Info

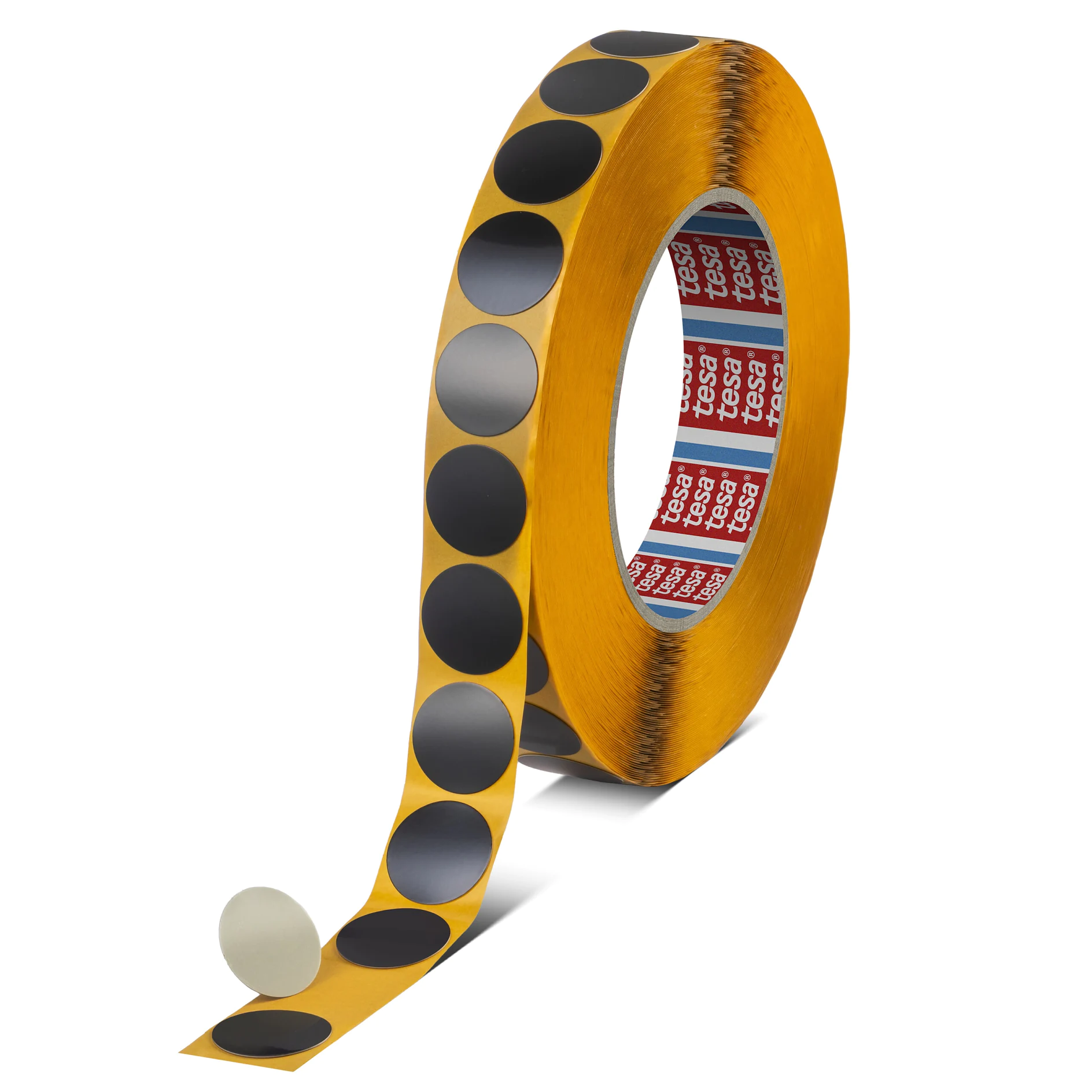

tesa® 54337 PV1 can be supplied as die cuts in roll or sheets individually to customer specific dimensions.

tesa’s automation and application solution department provides customized equipment and self-designed application tools to enhance productivity.

According to VDA 278 analysis, tesa® 54337 PV1 does not contain any single substances restricted by the drafted GB regulations (China) as well as the indoor concentration guideline by JAMA (Japanese Automotive Manufacturers Association and the Japanese Ministry of Health, Labor and Welfare Ministry (MHLW).

tesa’s automation and application solution department provides customized equipment and self-designed application tools to enhance productivity.

According to VDA 278 analysis, tesa® 54337 PV1 does not contain any single substances restricted by the drafted GB regulations (China) as well as the indoor concentration guideline by JAMA (Japanese Automotive Manufacturers Association and the Japanese Ministry of Health, Labor and Welfare Ministry (MHLW).