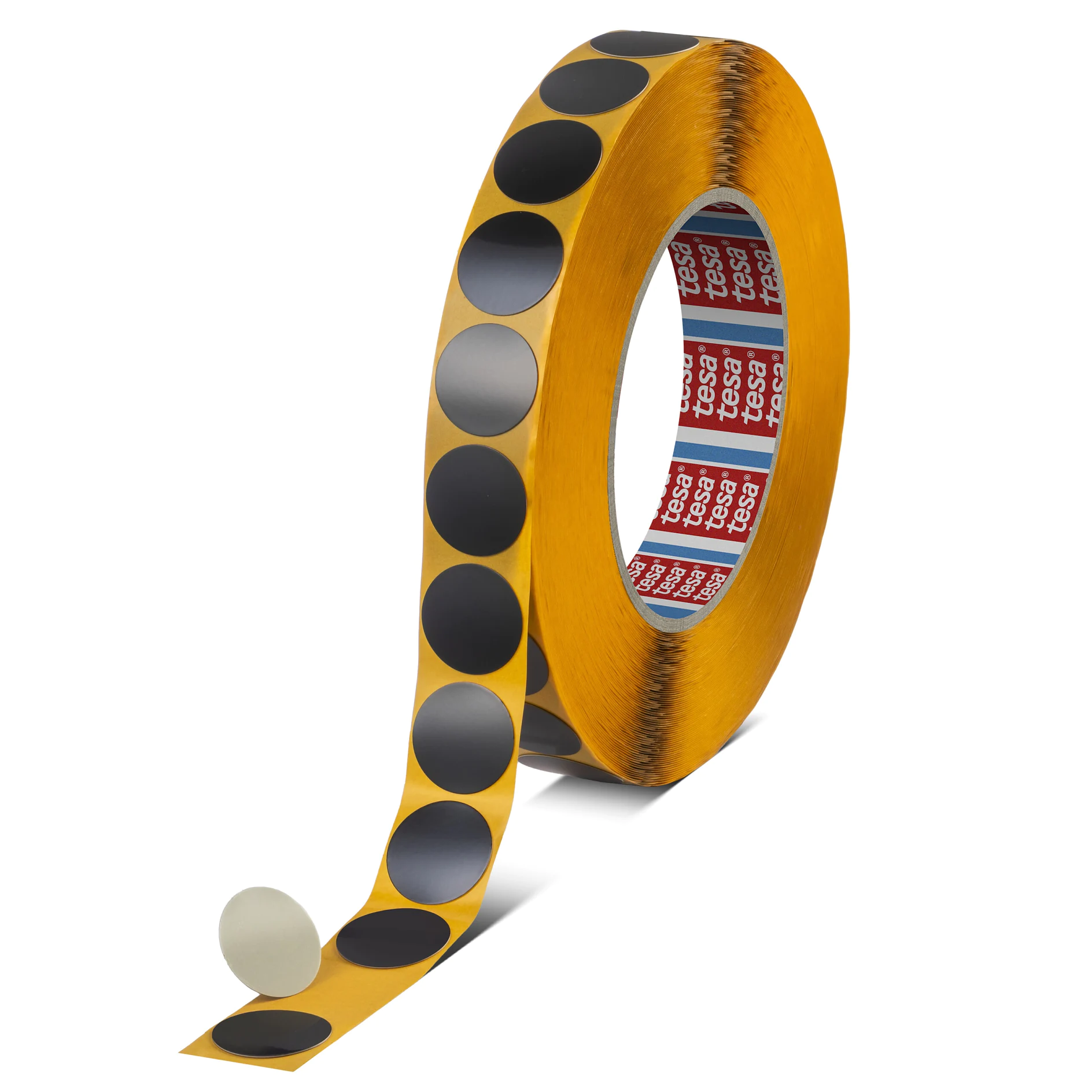

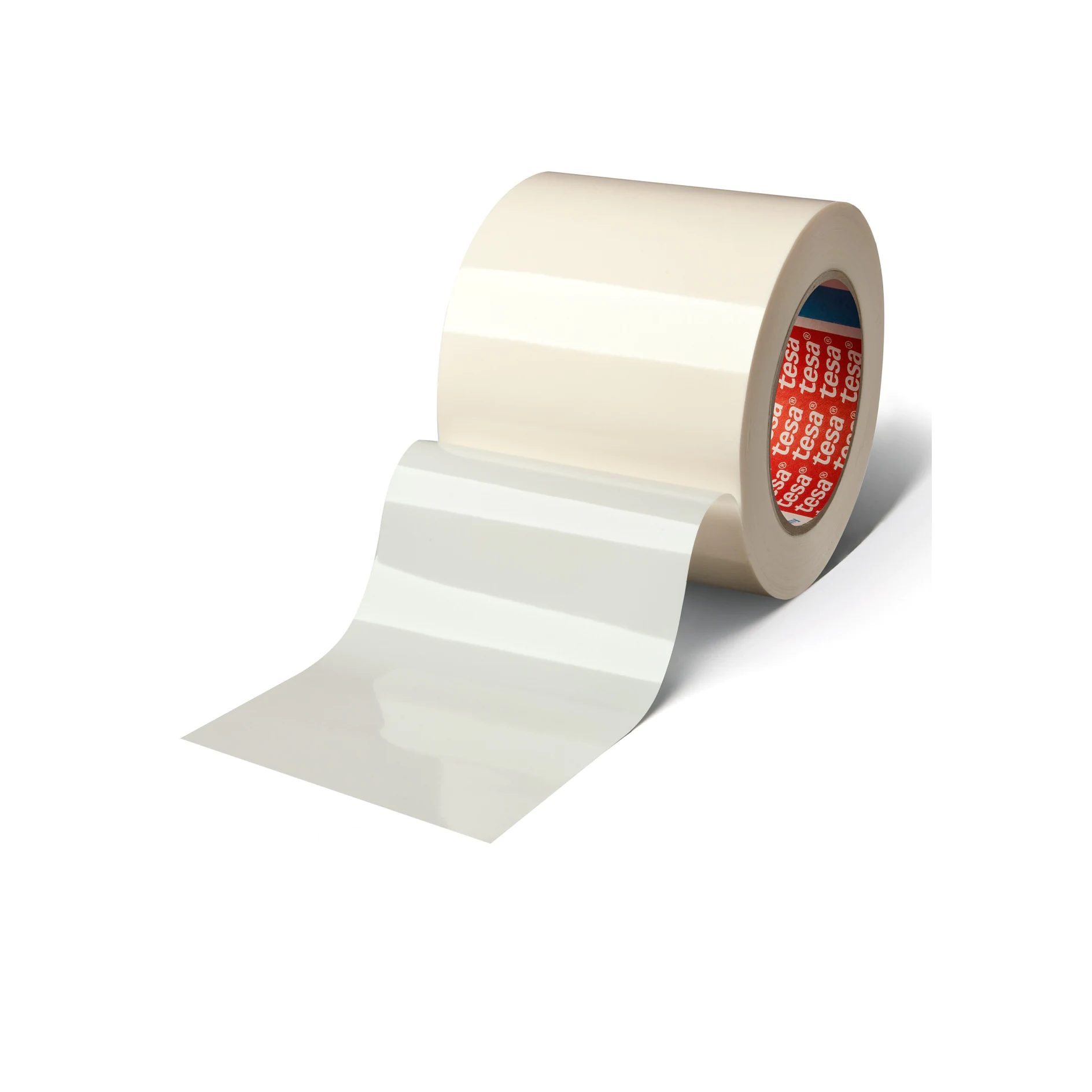

tesa® 54334 PV1 NoiseGuard

Acoustic sealing patch for hole covering applications

Product Features

- Very good acoustic insulation properties for higher drive comfort, comparable to a closed car body

- Reliable corrosion protection and sealing against water ingress

- Very good puncture resistance

Product description

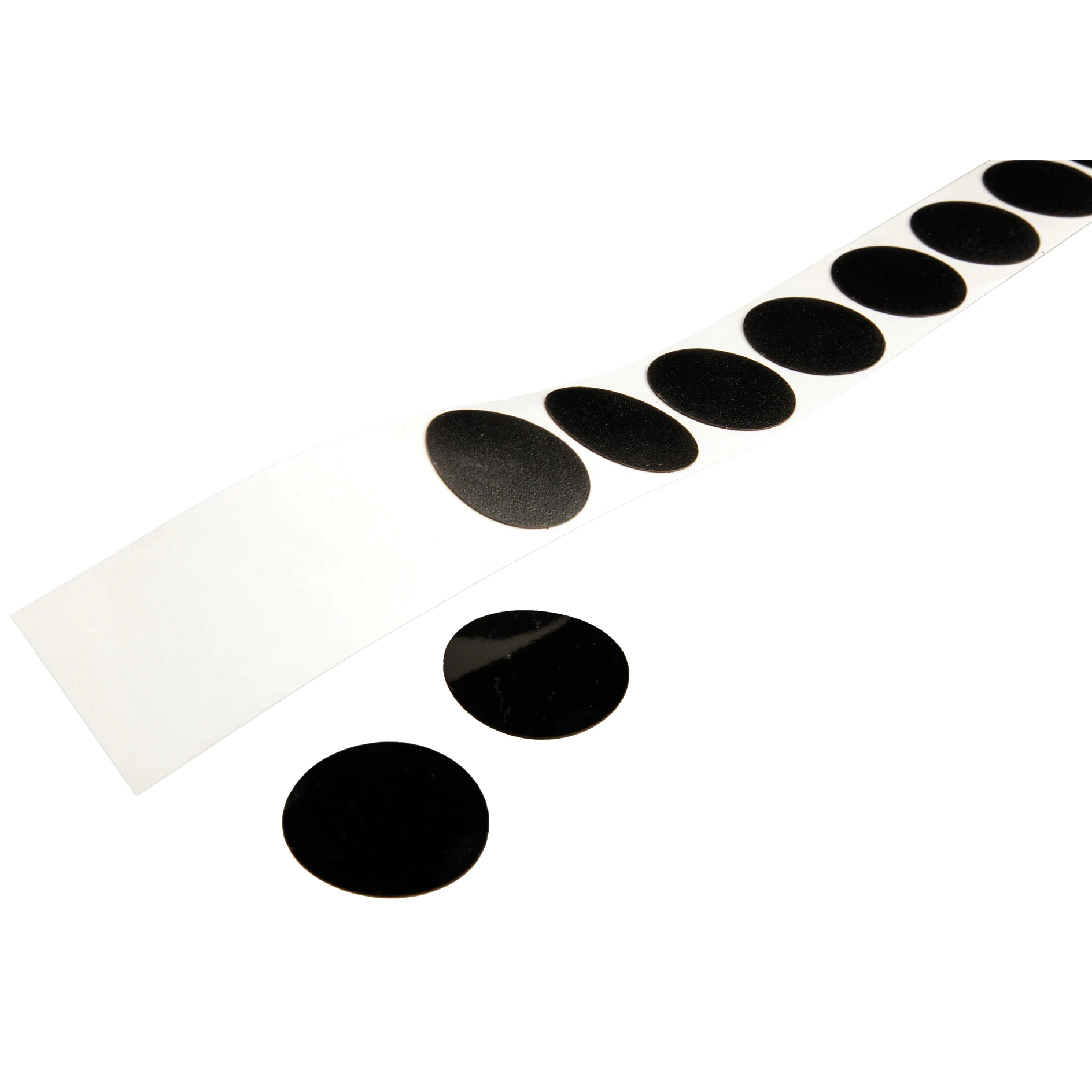

tesa® 54334 NoiseGuard significantly reduces and absorbs noise regardless of the hole size to enhance the acoustic comfort while driving. It is a multilayer composite, combining a outer black PET layer for superb black appearance with a thick, highly filled acrylic adhesive (1.1 kg/m²) and a strong inner PET layer for very good noise reduction. The high-performing tackified acrylic adhesive offers excellent hold on various surfaces, including perfect sealing properties.

Product details and specifications

Product Features

- Very good acoustic insulation properties for higher drive comfort, comparable to a closed car body

- Reliable corrosion protection and sealing against water ingress

- Very good puncture resistance

- Good UBC (PVC) compatibility and reliable paint anchorage

- Stone chipping protection

- Secure adhesion to steel, aluminum, plastics, painted substrates, and reinforced plastic substrates in automotive lightweight constructions

Application Fields

- unexposed exterior holes e.g. in portected underbody or wheel arch areas

- interior holes e.g. A-pillars, doors, floor

- application before and after paint shop along the automotive production process

- seamlessly integrates with tesa’s fully automated hole covering equipment ensuring ergonomic and consistent application

Product Construction

| Adhesive Type | modified acrylic |

|---|---|

| Backing material | Post consumer recycled PET |

| Color | black |

| Color of liner | brown |

| Liner Type | paper |

| Total thickness | 570 µm |

| Weight of liner | 80 g/m² |

Product Construction

| Adhesive Type | modified acrylic |

|---|---|

| Backing material | Post consumer recycled PET |

| Color | black |

| Color of liner | brown |

| Liner Type | paper |

| Total thickness | 570 µm |

| Weight of liner | 80 g/m² |

Properties / Performance Values

| Puncture resistance on e-coat, adhesive side (30 min; 160 °C) | 330 N |

|---|---|

| Sealing performance (IPX7 acc. ISO 20653:2023-08) | yes |

| Puncture resistance on e-coat, backing side (24 h; RT) | 1,000 N |

| Temperature resistance (30 min) | 160 °C |

| Noise damping | very good |

| Conformability | low |

| Stone chip resistance (SAE J400:2012-10 Method C) | 8A |

| Area weight | 1,100 g/m² |

| Puncture resistance on e-coat, adhesive side (24 h; RT) | 300 N |

| Puncture resistance on e-coat, backing side (30 min; 160 °C) | 1,200 N |

| Chemical Resistance | very good |

| Humidity sealing | very good |

| UBC / Paint compatibility | good |

Properties / Performance Values

| Puncture resistance on e-coat, adhesive side (30 min; 160 °C) | 330 N |

|---|---|

| Sealing performance (IPX7 acc. ISO 20653:2023-08) | yes |

| Puncture resistance on e-coat, backing side (24 h; RT) | 1,000 N |

| Temperature resistance (30 min) | 160 °C |

| Noise damping | very good |

| Conformability | low |

| Stone chip resistance (SAE J400:2012-10 Method C) | 8A |

| Area weight | 1,100 g/m² |

| Puncture resistance on e-coat, adhesive side (24 h; RT) | 300 N |

| Puncture resistance on e-coat, backing side (30 min; 160 °C) | 1,200 N |

| Chemical Resistance | very good |

| Humidity sealing | very good |

| UBC / Paint compatibility | good |

Adhesion to Values

| Adhesion to Steel (initial) | 14 N/cm |

|---|

Adhesion to Values

| Adhesion to Steel (initial) | 14 N/cm |

|---|

tesa® products prove their impressive quality day in, day out in demanding conditions and are regularly subjected to strict controls. All technical information and data above mentioned are provided to the best of our knowledge on the basis of our practical experience. They shall be considered as average values and are not appropriate for a specification. Therefore tesa SE can make no warranties, expressed or implied, including, but not limited to any implied warranty of merchantability or fitness for a particular purpose. The user is responsible for determining whether the tesa® product is fit for a particular purpose and suitable for the user’s method of application. If you are in any doubt, our technical staff will be glad to support you.

Downloads

Download the files below for more technical details and information on this product.