Additional Info

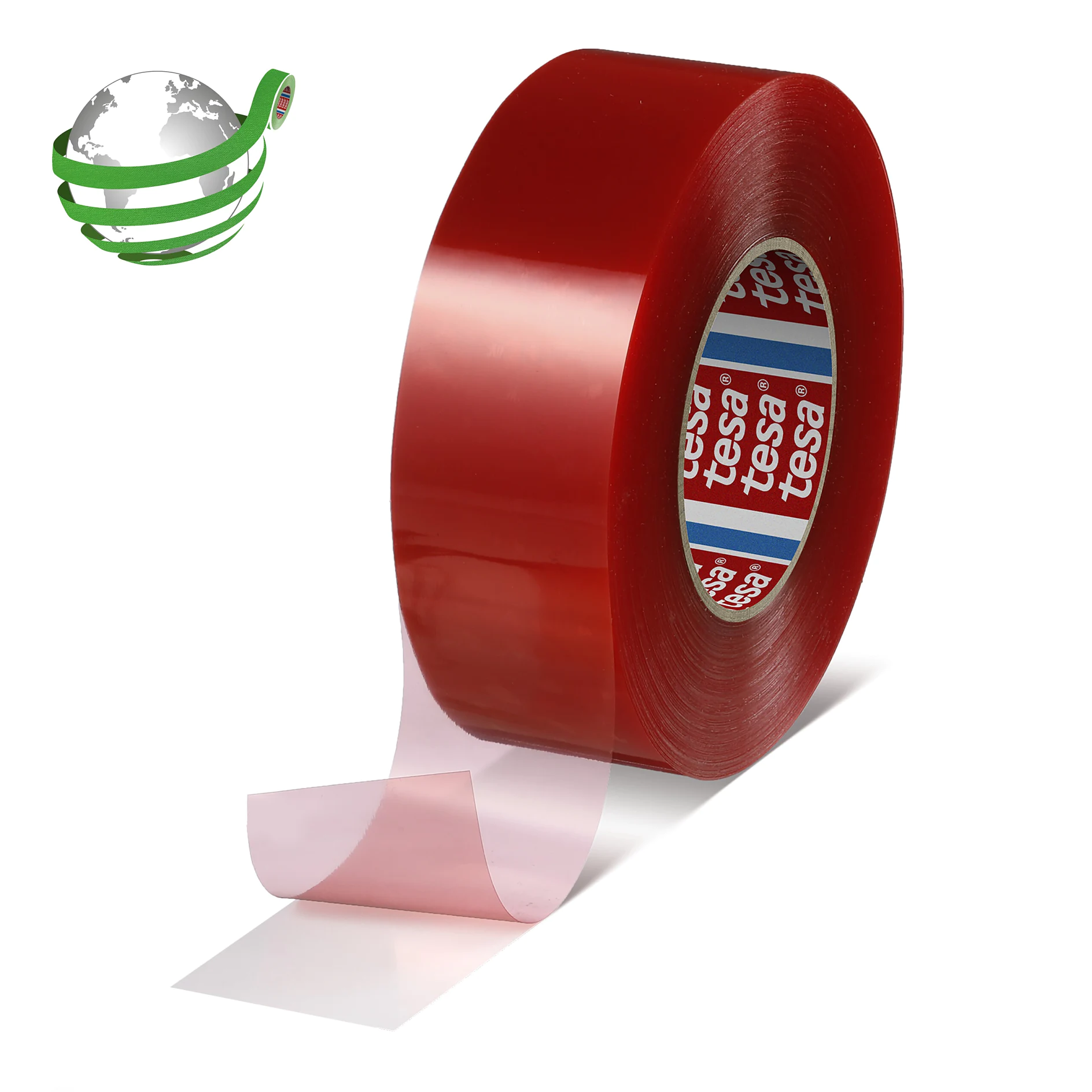

tesa® 4917 is also available with fingerlift (extended liner) for fast liner removal.

For Spools: To ensure correct and reliable tape application, we strongly recommend the use of a tesa® dispenser. If a tesa® dispenser is not used, it is essential to use a pressure roller to ensure optimal application.

For Spools: To ensure correct and reliable tape application, we strongly recommend the use of a tesa® dispenser. If a tesa® dispenser is not used, it is essential to use a pressure roller to ensure optimal application.