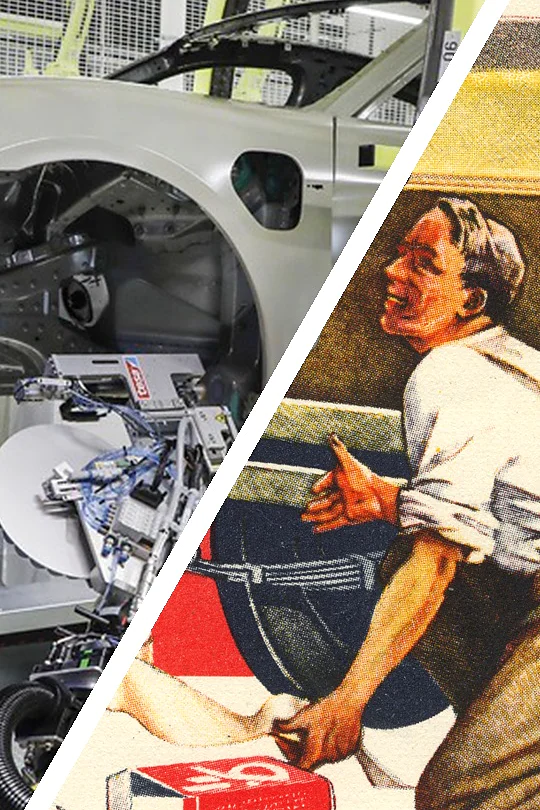

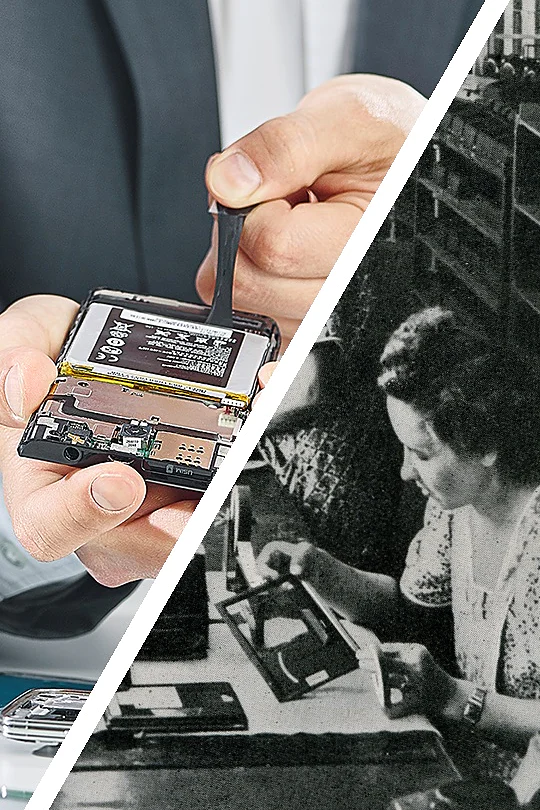

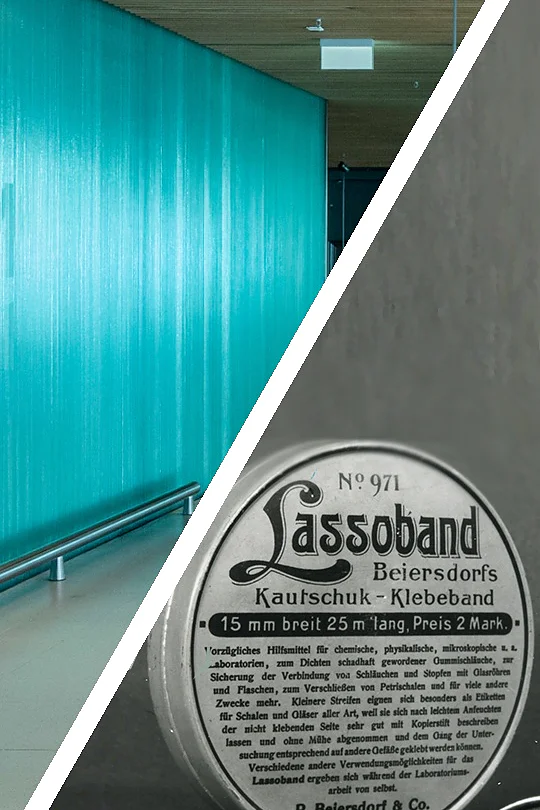

Anyone who envisions the future must also research it. To show appreciation and respect for the trade industry, tesa develops masterpieces for master craftsmen – with a great deal of inventive talent and high-tech. Nowadays professionals may show their true colors with confidence, for example, when painting and varnishing. With the tesa precision masking tape, coated with Japanese Washi paper, color bleeding and color gradients have no chance. The popular predecessor model, tesakrepp®, gave a "clear edge" to automotive painting 85 years ago.

125 years of innovation – tesa holds the world together

Read more