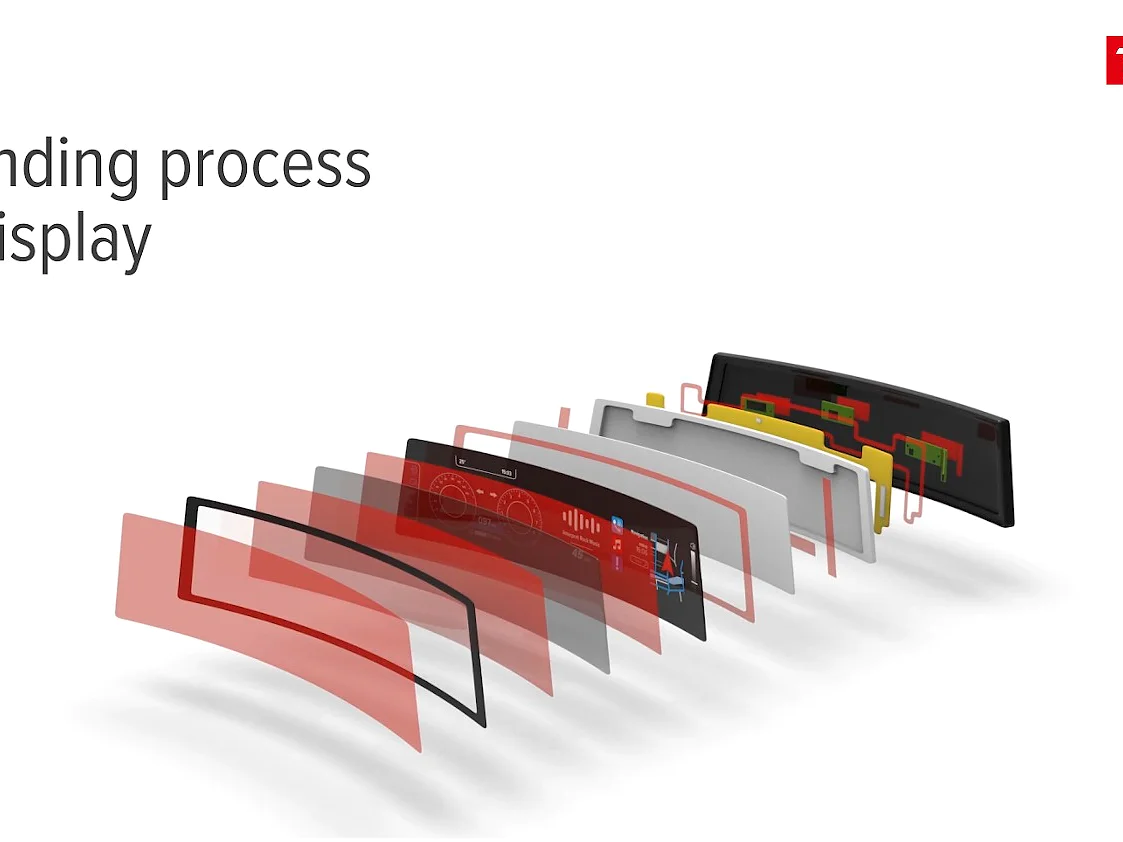

This challenge inspired tesa to develop debonding tapes – an innovative adhesive solution that provides strong bonds when needed while allowing for clean removal when required. These revolutionary tapes help designers and manufacturers reduce waste, simplify product disassembly, and make circular economy principles a practical reality.

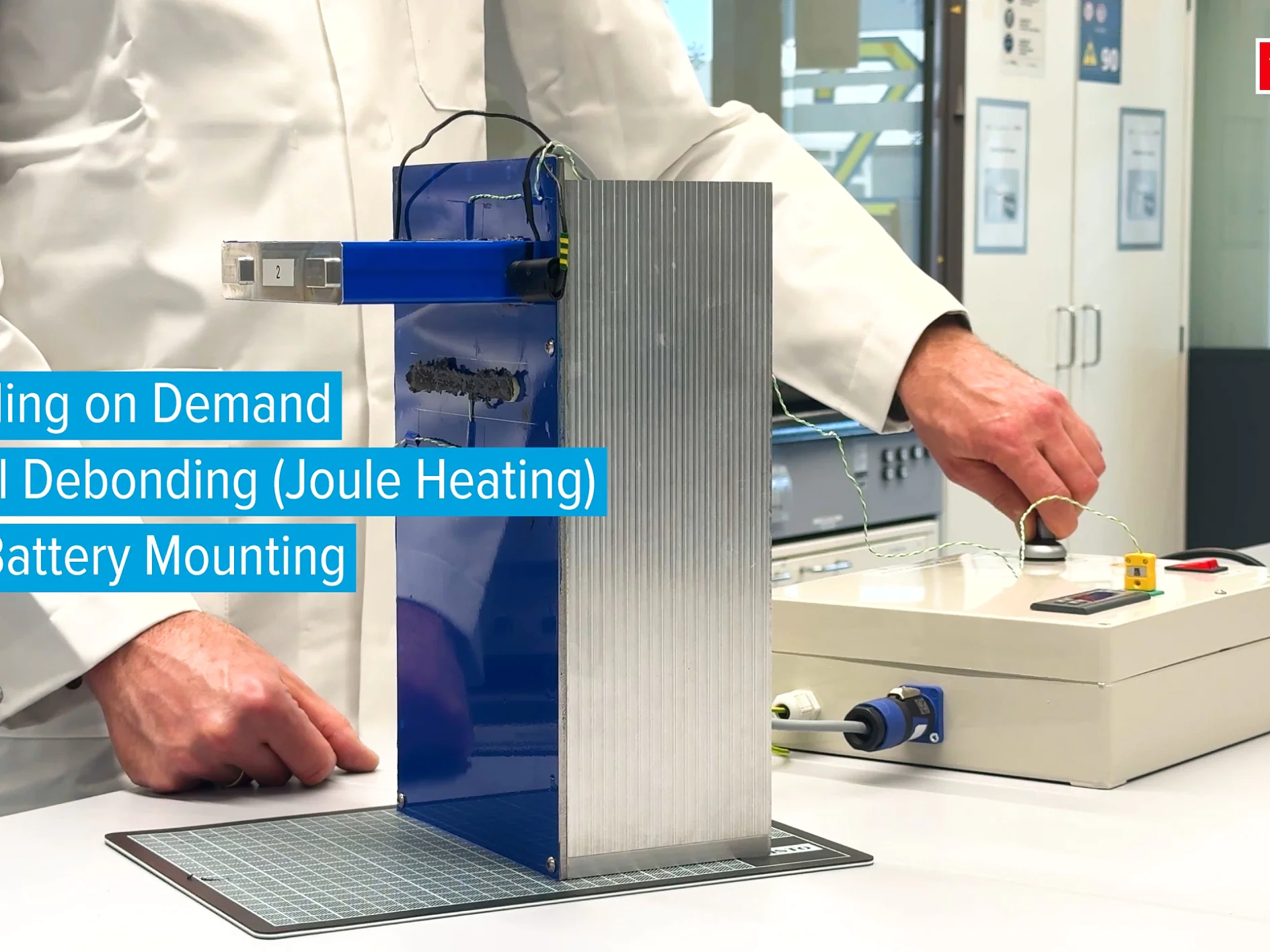

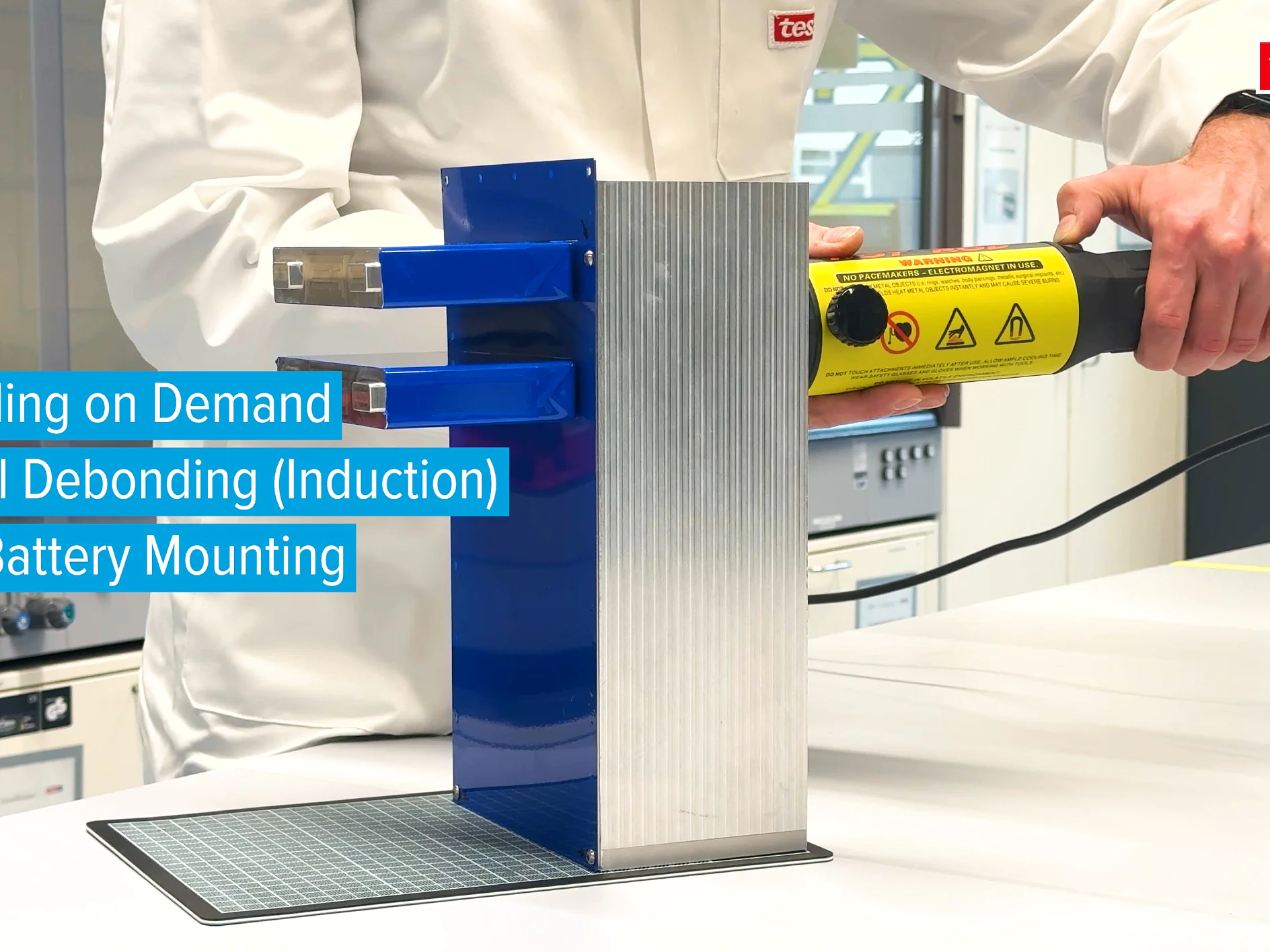

Our journey began more than a decade ago with the groundbreaking tesa® Bond & Detach technology, which set a new standard for residue-free tape removal. Building on this breakthrough, we are now exploring even more advanced solutions. Our latest developments include debonding tapes that respond to various triggers such as electricity, induction, infrared light, or heat. This advancement in structural bonding technology promises to transform traditional fastening methods and revolutionize the adhesive industry.

Our debonding tapes provide fast, safe, and reliable bonds with exceptional strength – yet can be completely removed whenever required. This innovative solution enables our customers to conserve resources, promote sustainability, maintain a competitive edge, and confidently adapt to changing regulations.