Additional Info

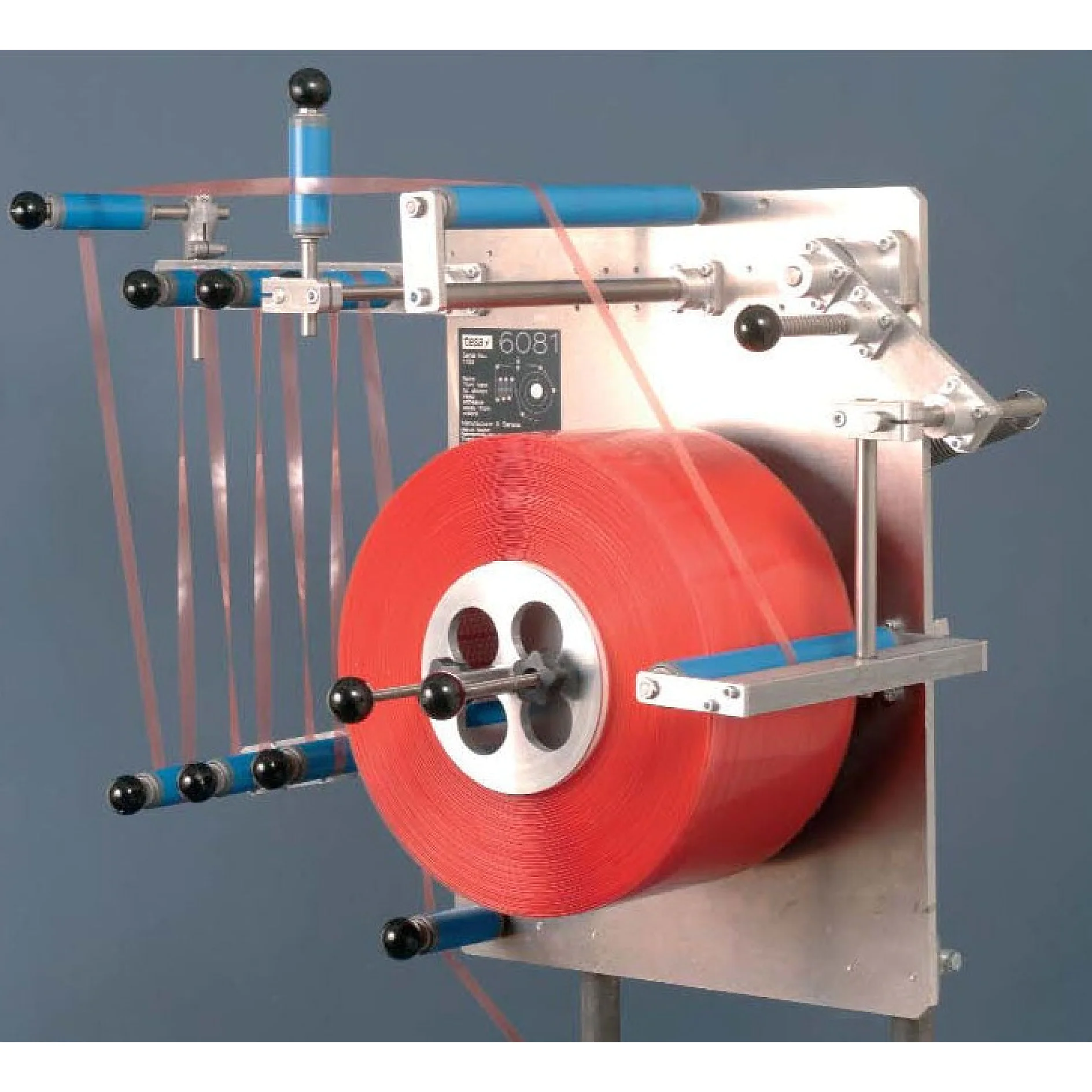

Integrate the spool dispenser into your production line easily

In the product manual you will find drawings of all sections and item listings. The only part which eventually needs to be replaces may be the brake belt. In case you need any spare parts please refer to this item listings and contact:

Nauber-Feinmechanik

Thomas-Mann-Str. 29

D-22175 Hamburg

Tel.: +49 40 / 640 14 16

Fax.: +49 40 / 640 76 92

info@nauber-feinmechanik.de

- Easy mounting and retro-fitting to existing production lines.

- Modify to left or right hand production direction.

- Tape unwinding is done mechanically by the propulsion of the profile.

- Delivered ready-to-run without any electrical components.

- Ask for our tesa engineering support.

In the product manual you will find drawings of all sections and item listings. The only part which eventually needs to be replaces may be the brake belt. In case you need any spare parts please refer to this item listings and contact:

Nauber-Feinmechanik

Thomas-Mann-Str. 29

D-22175 Hamburg

Tel.: +49 40 / 640 14 16

Fax.: +49 40 / 640 76 92

info@nauber-feinmechanik.de