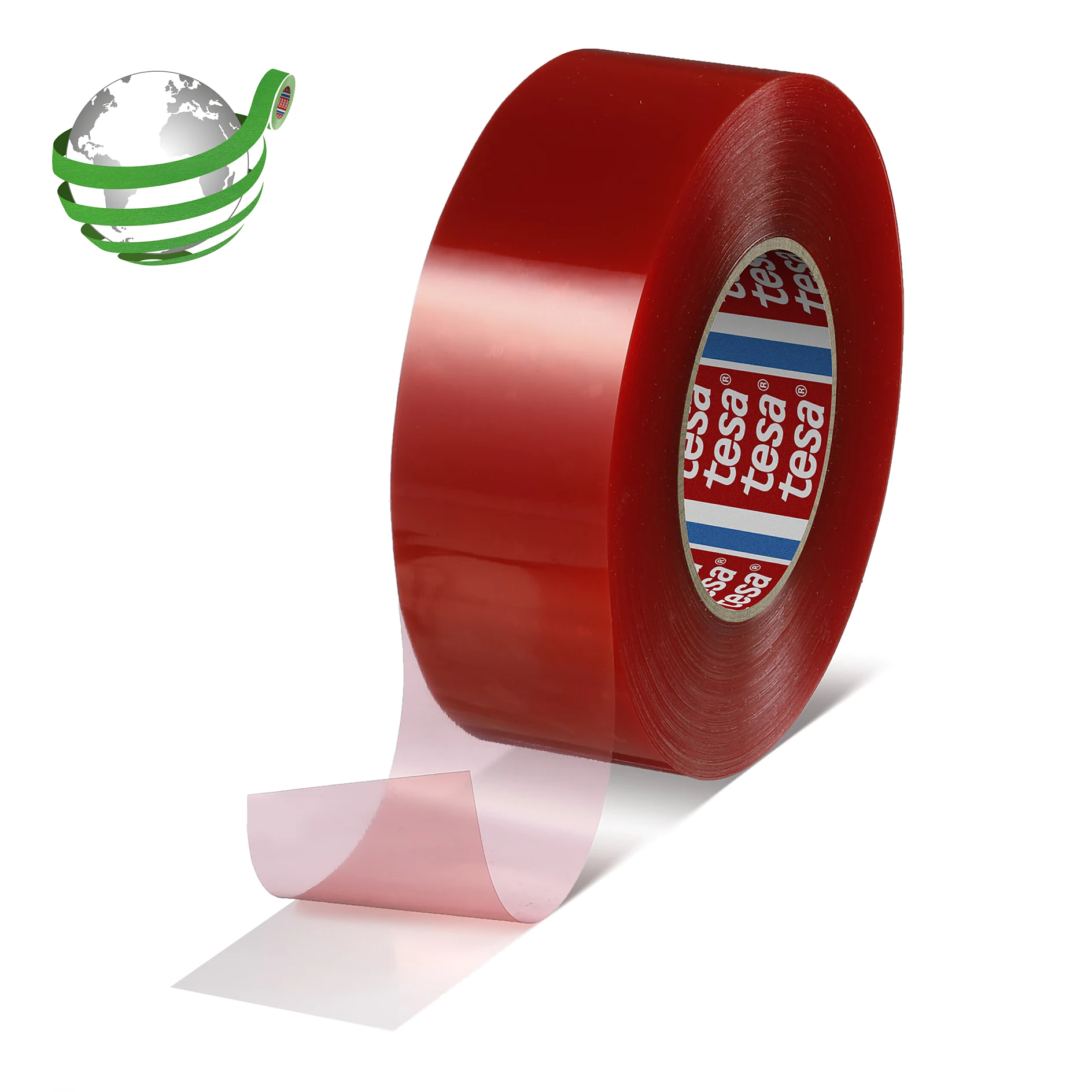

tesa® 4950 - LSE Filmic Mounting Tape

100µm LSE double-sided transparent PET film tape

Sustainable Aspects

- 90% PCR PET in the backing

- Responsibly sourced paper liner (certified)

Product description

tesa® 4950 is a high-performance, double-sided transparent PET film tape designed for reliable bonding on low surface energy (LSE) substrates. With a total thickness of 100µm and a 12µm PET backing made from 90% post-consumer recycled content, it combines sustainability with technical excellence. The tackified acrylic adhesive ensures strong initial tack and superior shear strength, even under demanding environmental conditions.

Product details and specifications

Application Fields

- Versatile bonding solution for a wide range of demanding industrial applications

- Enables primerless adhesion to low surface energy (LSE) substrates such as PP, PE, and EPDM

- Ideal for long-term mounting on hard-to-bond materials, including gaskets and molded components

- For industrial assembly where clean aesthetics, dimensional stability, and transparent bonding are critical

Sustainable Aspects

- 90% PCR PET in the backing

- Responsibly sourced paper liner (certified)

Product Construction

| Backing material | Post consumer recycled PET |

|---|---|

| Colour | transparent |

| Colour of liner | brown/blue logo |

| Thickness of liner | 69 µm |

| Total thickness | 100 µm |

| Type of adhesive | tackified acrylic |

| Weight of liner | 80 g/m² |

Product Construction

| Backing material | Post consumer recycled PET |

|---|---|

| Colour | transparent |

| Colour of liner | brown/blue logo |

| Thickness of liner | 69 µm |

| Total thickness | 100 µm |

| Type of adhesive | tackified acrylic |

| Weight of liner | 80 g/m² |

Properties / Performance Values

| Elongation at break | 50 % |

|---|---|

| Tensile strength | 20 N/cm |

| Temperature resistance short term duration | 200 °C |

| Softener resistance | very good |

| Static shear resistance at 40°C | very good |

| Static shear resistance at 23°C | very good |

| Temperature resistance long term duration | 100 °C |

| Tack | very good |

| Chemical resistance | good |

| Humidity resistance | very good |

| Minimum temperature resistance | -40 °C |

| Ageing resistance (UV) | good |

| Static shear resistance at 70°C | very good |

Properties / Performance Values

| Elongation at break | 50 % |

|---|---|

| Tensile strength | 20 N/cm |

| Temperature resistance short term duration | 200 °C |

| Softener resistance | very good |

| Static shear resistance at 40°C | very good |

| Static shear resistance at 23°C | very good |

| Temperature resistance long term duration | 100 °C |

| Tack | very good |

| Chemical resistance | good |

| Humidity resistance | very good |

| Minimum temperature resistance | -40 °C |

| Ageing resistance (UV) | good |

| Static shear resistance at 70°C | very good |

Adhesion to Values

| Adhesion to PC (initial) | 7 N/cm |

|---|---|

| Adhesion to PE (initial) | 5 N/cm |

| Adhesion to PP (initial) | 6.6 N/cm |

| Adhesion to Steel (initial) | 7.5 N/cm |

Adhesion to Values

| Adhesion to PC (initial) | 7 N/cm |

|---|---|

| Adhesion to PE (initial) | 5 N/cm |

| Adhesion to PP (initial) | 6.6 N/cm |

| Adhesion to Steel (initial) | 7.5 N/cm |

tesa® products prove their impressive quality day in, day out in demanding conditions and are regularly subjected to strict controls. All technical information and data above mentioned are provided to the best of our knowledge on the basis of our practical experience. They shall be considered as average values and are not appropriate for a specification. Therefore tesa SE can make no warranties, expressed or implied, including, but not limited to any implied warranty of merchantability or fitness for a particular purpose. The user is responsible for determining whether the tesa® product is fit for a particular purpose and suitable for the user’s method of application. If you are in any doubt, our technical staff will be glad to support you.

Downloads

Download the files below for more technical details and information on this product.