Additional Info

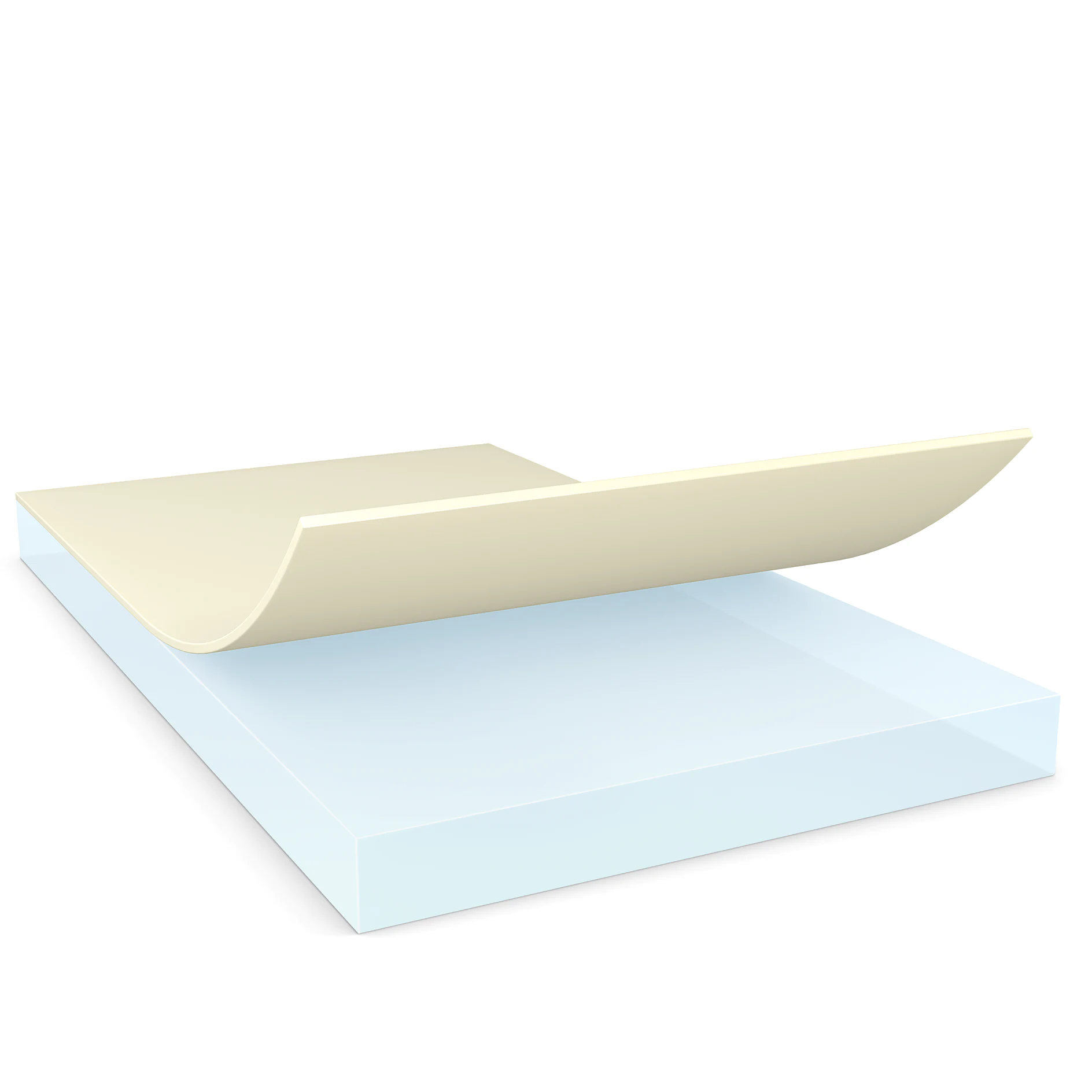

Before using our adhesion promoter, the bonding surface, i.e. the substrate, should be free of dust, grease, oil, moisture, and other contaminants. Therefore, we highly recommend cleaning the substrate with a lint-free cloth using solvents, such as ethanol or isopropanol.

tesa® 60162 Mounting Rework can be applied in an inkjet process or with a lint-free cloth, brush or sponge, once the surface has been cleaned. The entire surface should be coated thinly with adhesion promoter in order to reach the highest bonding performance. It is important to wait at least 30 seconds to 15 minutes, in order to give solvents time to evaporate. Please make sure to keep the prepared surface free of contaminants prior to applying the tape. Once the substrate has been properly pre-treated with tesa® 60162 Mounting Rework, the bond should be established within 30 minutes.

Please note that due to the multitude of available substrate formulations in the marketplace, it is recommended to test our tesa® Mounting Rework prior to usage.

The shelf life of this product amounts to at least 24 months after production, when stored at room temperature in its sealed original container. For further information and advice on safe handling please refer to our material safety data sheet (MSDS), which is available upon request.

Solids content including all reactive substances.

tesa® 60162 Mounting Rework can be applied in an inkjet process or with a lint-free cloth, brush or sponge, once the surface has been cleaned. The entire surface should be coated thinly with adhesion promoter in order to reach the highest bonding performance. It is important to wait at least 30 seconds to 15 minutes, in order to give solvents time to evaporate. Please make sure to keep the prepared surface free of contaminants prior to applying the tape. Once the substrate has been properly pre-treated with tesa® 60162 Mounting Rework, the bond should be established within 30 minutes.

Please note that due to the multitude of available substrate formulations in the marketplace, it is recommended to test our tesa® Mounting Rework prior to usage.

The shelf life of this product amounts to at least 24 months after production, when stored at room temperature in its sealed original container. For further information and advice on safe handling please refer to our material safety data sheet (MSDS), which is available upon request.

Solids content including all reactive substances.