tesa® 77815 Primerless Line

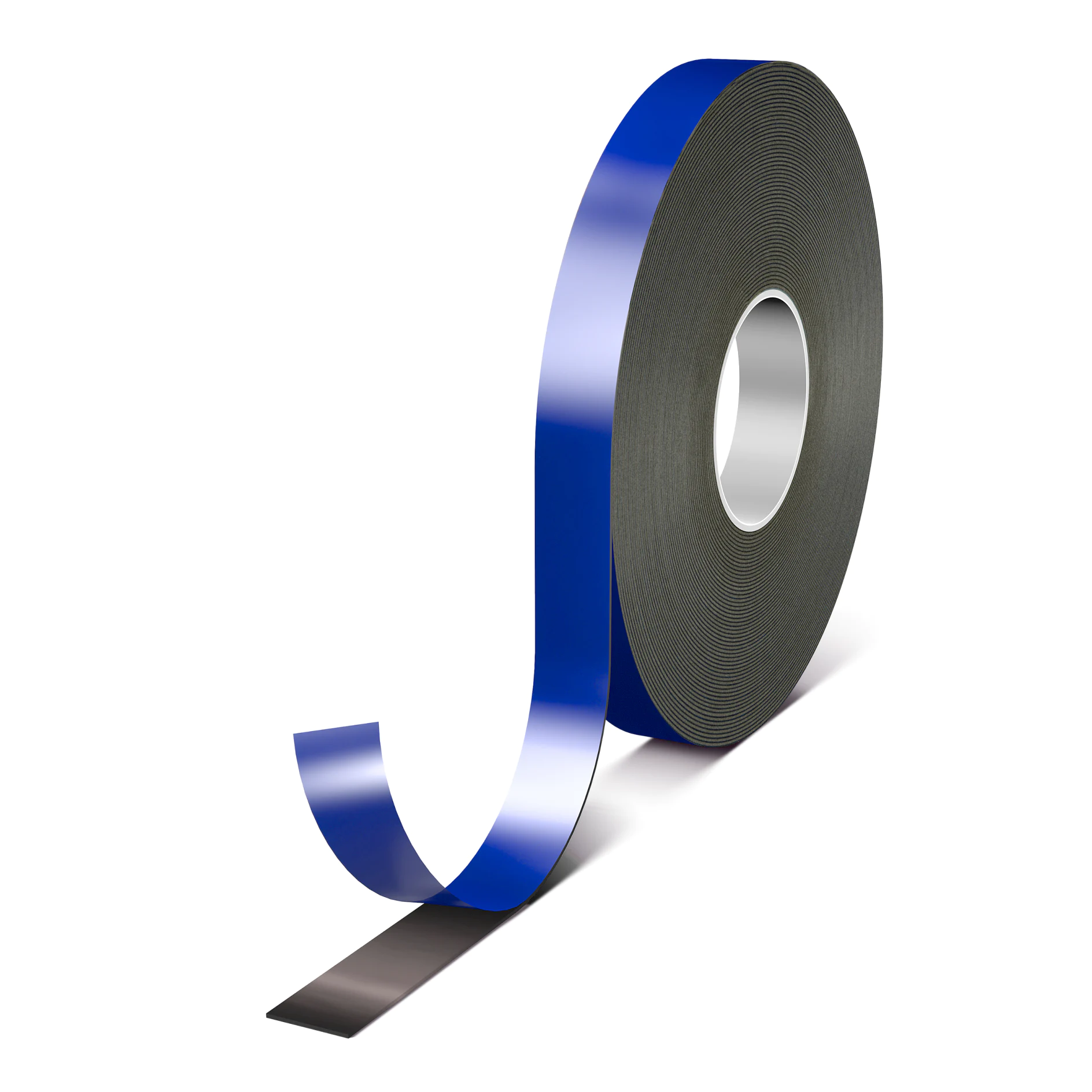

1.5 mm double-sided acrylic foam tape for mounting of automotive exterior attachment part

Product Features

- Features:

- ▪ High initial performance on LSE plastics and difficult-to-bond OEM clear coats

- ▪ Excellent bonding stability at wider range of temperatures

Product description

tesa® ACXplus 77815 can help you eliminate the primer in your process!

Its high-performance LSE adhesive creates an efficient and secure bond to typical automotive attachment parts made of LSE (like PP and PP/EPDM) and MSE (like ABS) plastics without primer. In addition, our product also has excellent adhesive properties when it comes to different types of OEM clear coats. (LSE: low surface energy; MSE: medium surface energy). Thanks to its viscoelastic acrylic foam core, tesa® ACXplus 77815 Primerless Line has the ability to absorb and dissipate dynamic and static loads.

0.5, 0.8 mm and 1.1 mm thicknesses are available

Product details and specifications

Product Features

- Features:

- ▪ High initial performance on LSE plastics and difficult-to-bond OEM clear coats

- ▪ Excellent bonding stability at wider range of temperatures

- ▪ Reaches high peel-adhesion level right after application

- ▪ Superior peel adhesion on PP substrates, even at an application temperature as low as 5°C

- ▪ Viscoelastic acrylic foam core to compensate for different thermal elongation of bonded parts

- ▪ Outstanding wet-out property

- ▪ High humidity and UV resistance

- Benefits:

- ▪ Eliminates the primer in the production process

- ▪ Enables a much more efficient and robust application

- ▪ Reduces the total process cost

- ▪ Realizes healthier working conditions

- ▪ Achieves a more environmentally friendly production

Application Fields

▪ Body side moldings and decorative trims

▪ Emblems

▪ Spoilers

▪ Antennas

▪ Pillar appliqués

▪ PDC mounting

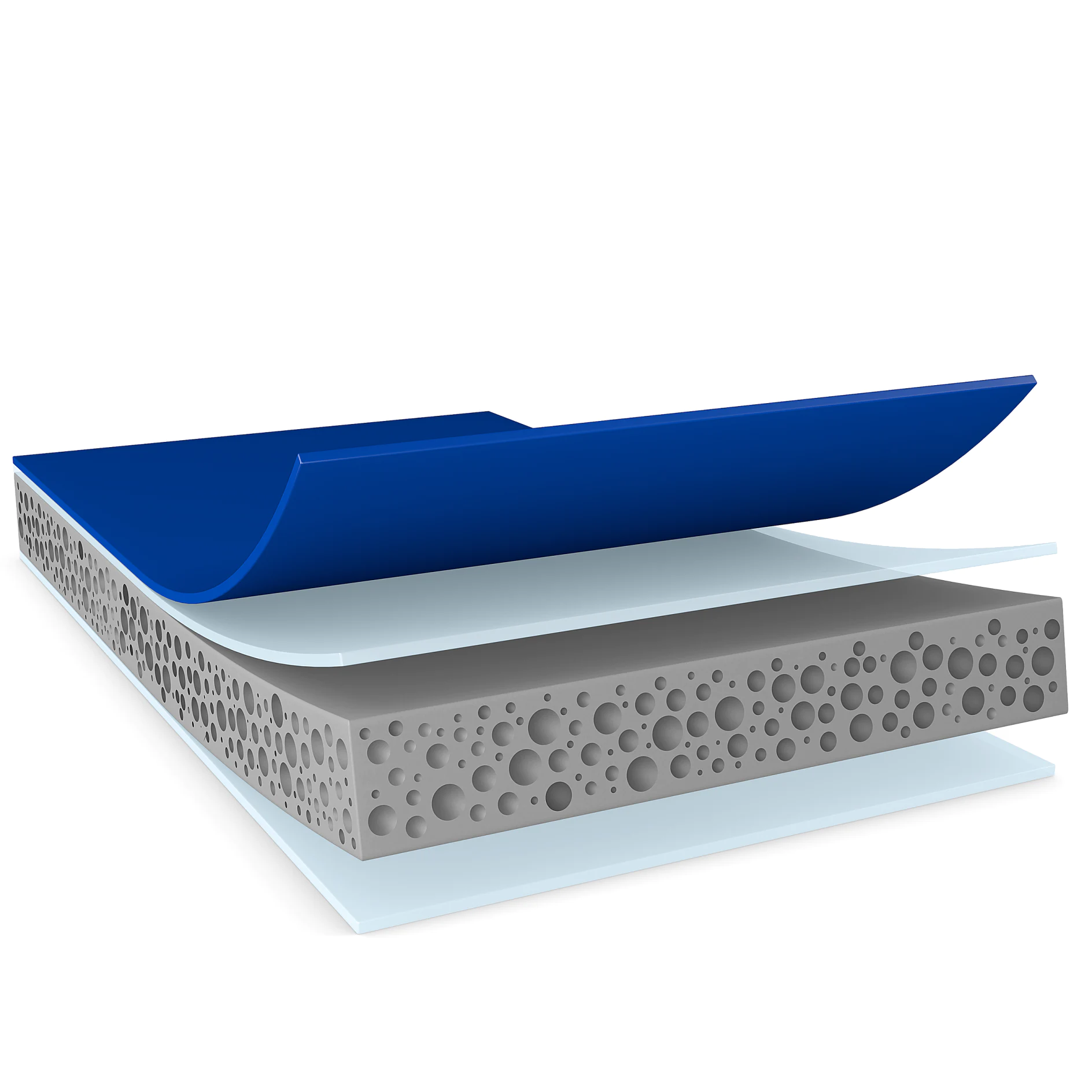

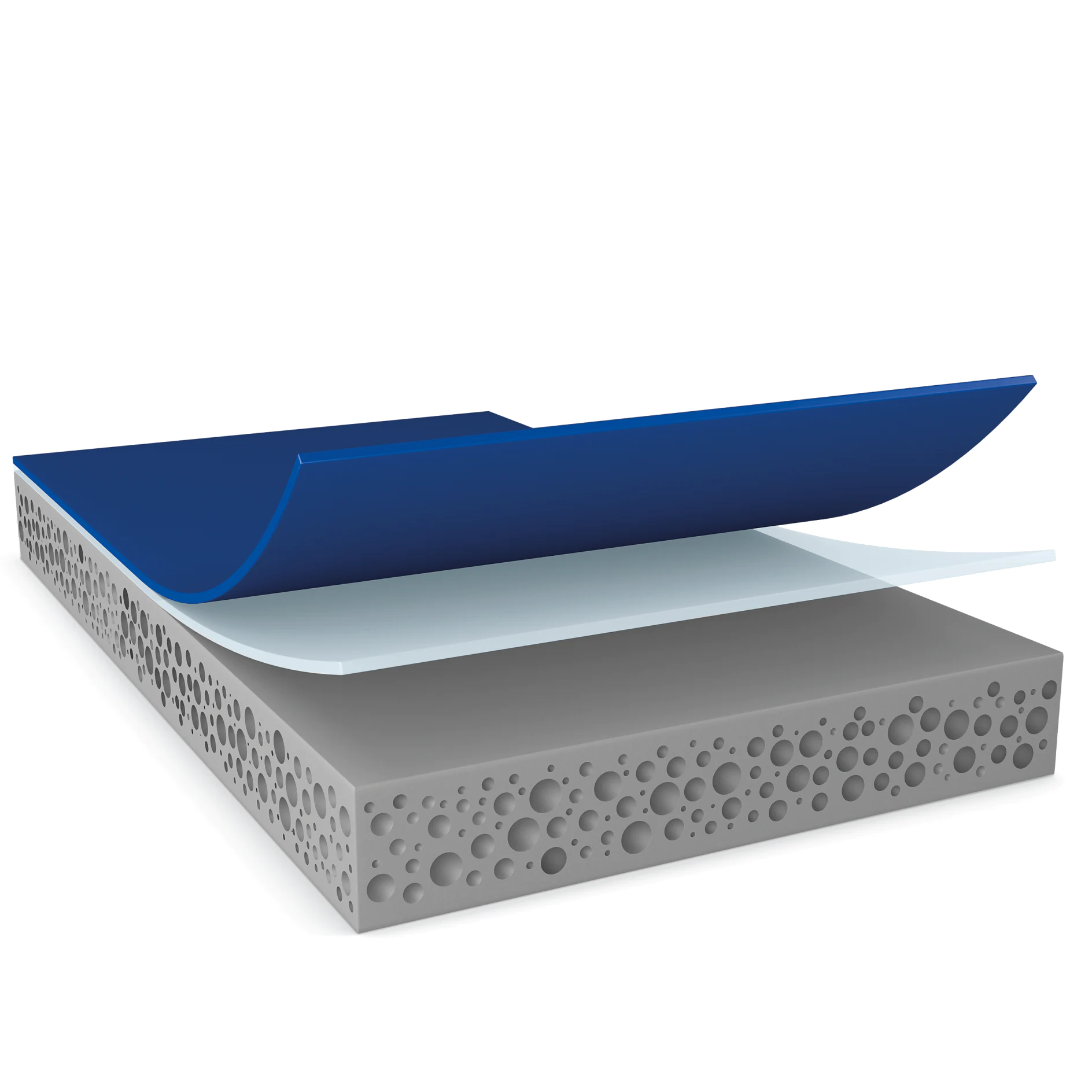

Product Construction

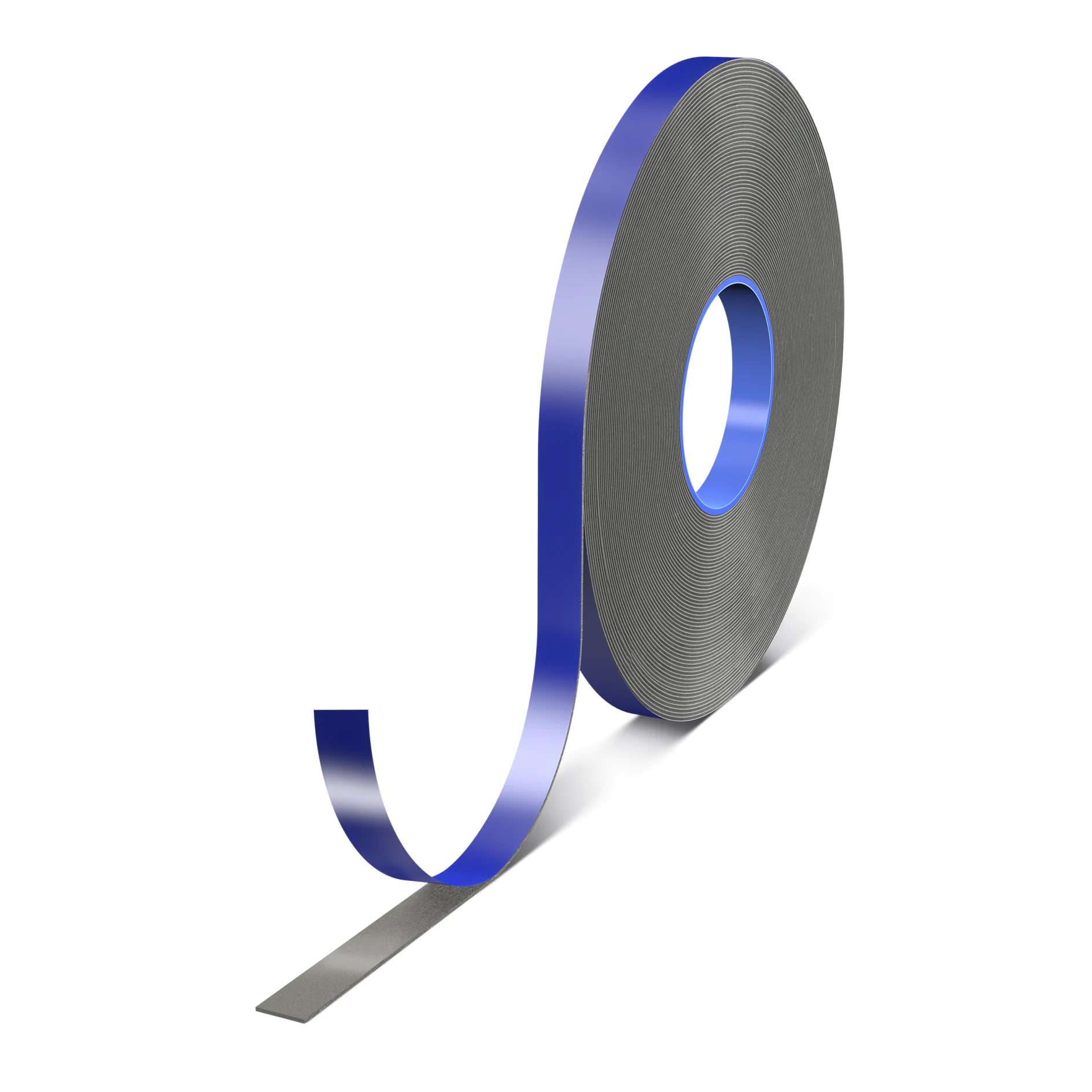

| Adhesive Type | LSE |

|---|---|

| Backing material | Acrylic foam |

| Color | gray |

| Color of liner | blue |

| Liner Type | PE |

| Total thickness | 1,500 µm |

Product Construction

| Adhesive Type | LSE |

|---|---|

| Backing material | Acrylic foam |

| Color | gray |

| Color of liner | blue |

| Liner Type | PE |

| Total thickness | 1,500 µm |

Properties / Performance Values

| Static shear resistance at 90°C | very good |

|---|---|

| Ageing resistance (UV) | good |

| T-block | very good |

| Humidity resistance | very good |

| Temperature range | -40 to +80 °C |

| L-jig | good |

Properties / Performance Values

| Static shear resistance at 90°C | very good |

|---|---|

| Ageing resistance (UV) | good |

| T-block | very good |

| Humidity resistance | very good |

| Temperature range | -40 to +80 °C |

| L-jig | good |

Adhesion to Values

| Adhesion to ABS (after 3 days) | 34 N/cm |

|---|---|

| Adhesion to ABS (initial, after 1 minute) | 32 N/cm |

| Adhesion to PP (after 3 days) | 44 N/cm |

| Adhesion to PP (initial, 1 min) | 34 N/cm |

| Adhesion to Steel (after 14 days) | 39 N/cm |

| Adhesion to Steel (initial, 1 min) | 36 N/cm |

| Adhesion to Steel (after 3 days) | 39 N/cm |

Adhesion to Values

| Adhesion to ABS (after 3 days) | 34 N/cm |

|---|---|

| Adhesion to ABS (initial, after 1 minute) | 32 N/cm |

| Adhesion to PP (after 3 days) | 44 N/cm |

| Adhesion to PP (initial, 1 min) | 34 N/cm |

| Adhesion to Steel (after 14 days) | 39 N/cm |

| Adhesion to Steel (initial, 1 min) | 36 N/cm |

| Adhesion to Steel (after 3 days) | 39 N/cm |

Download the files below for more technical details and information on this product.