Additional Info

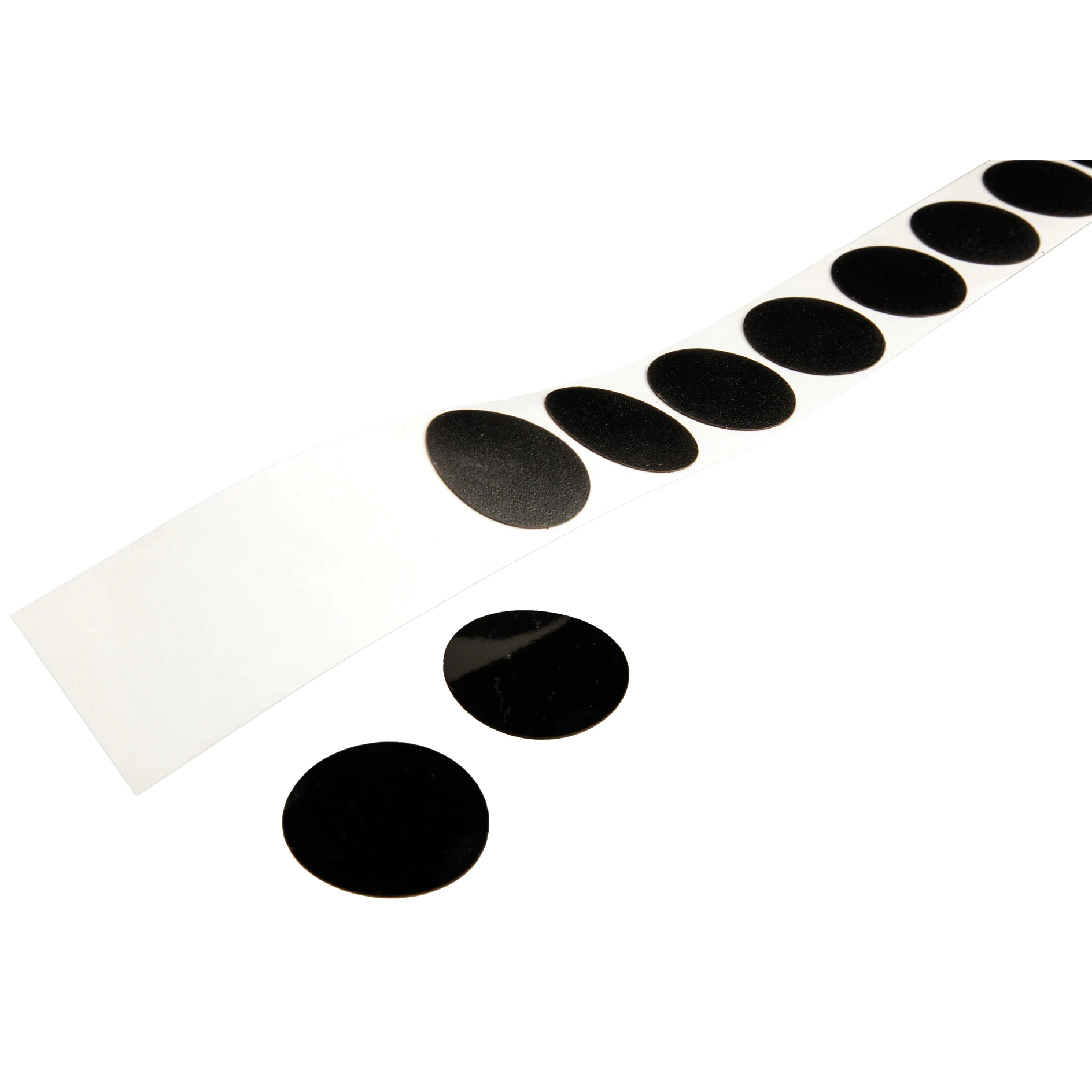

tesa® 54717 can be supplied as die-cuts in roll or sheets individually to customer specific dimensions.

Our application process engineers support with customized equipment and self-designed application tools to enhance productivity.

Our application process engineers support with customized equipment and self-designed application tools to enhance productivity.