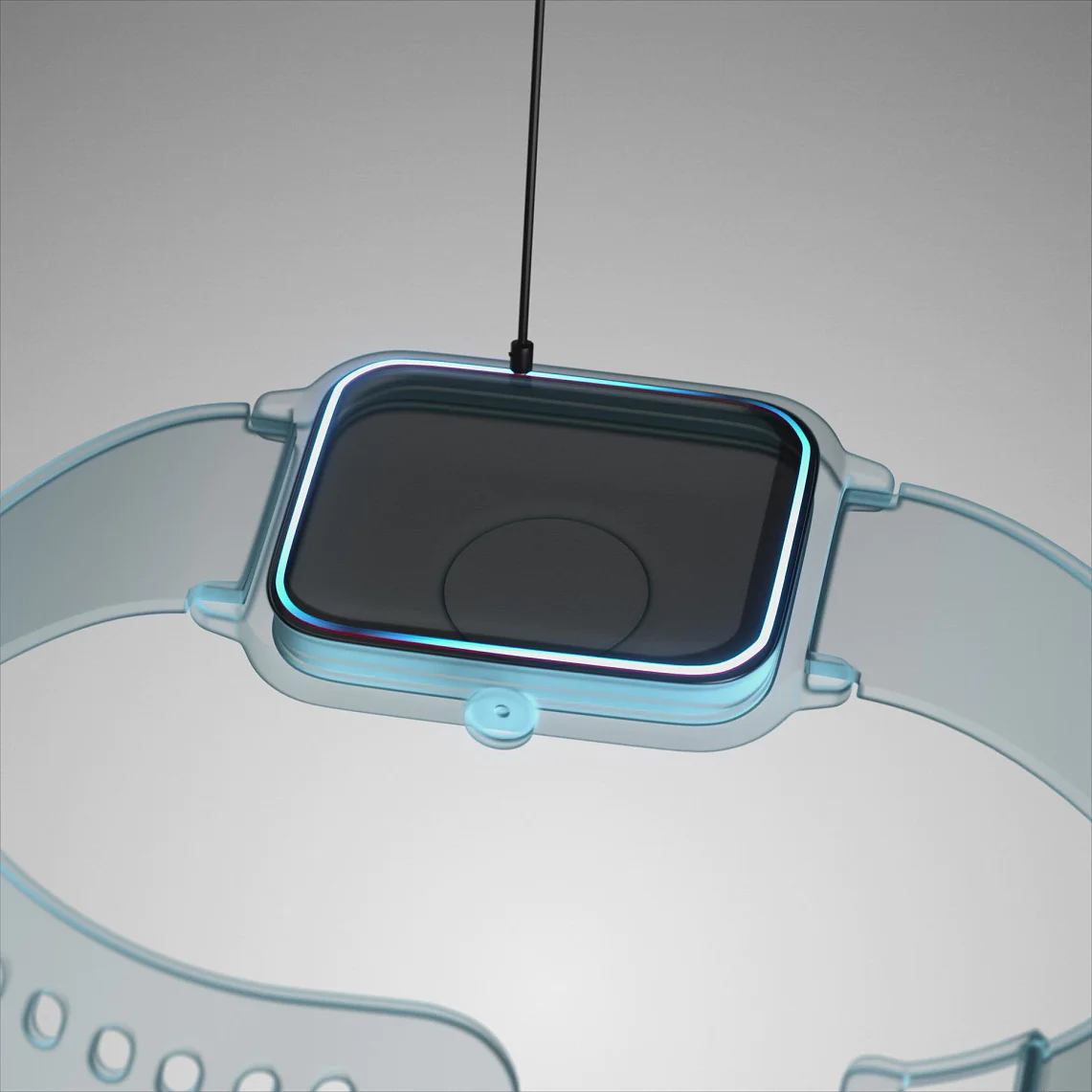

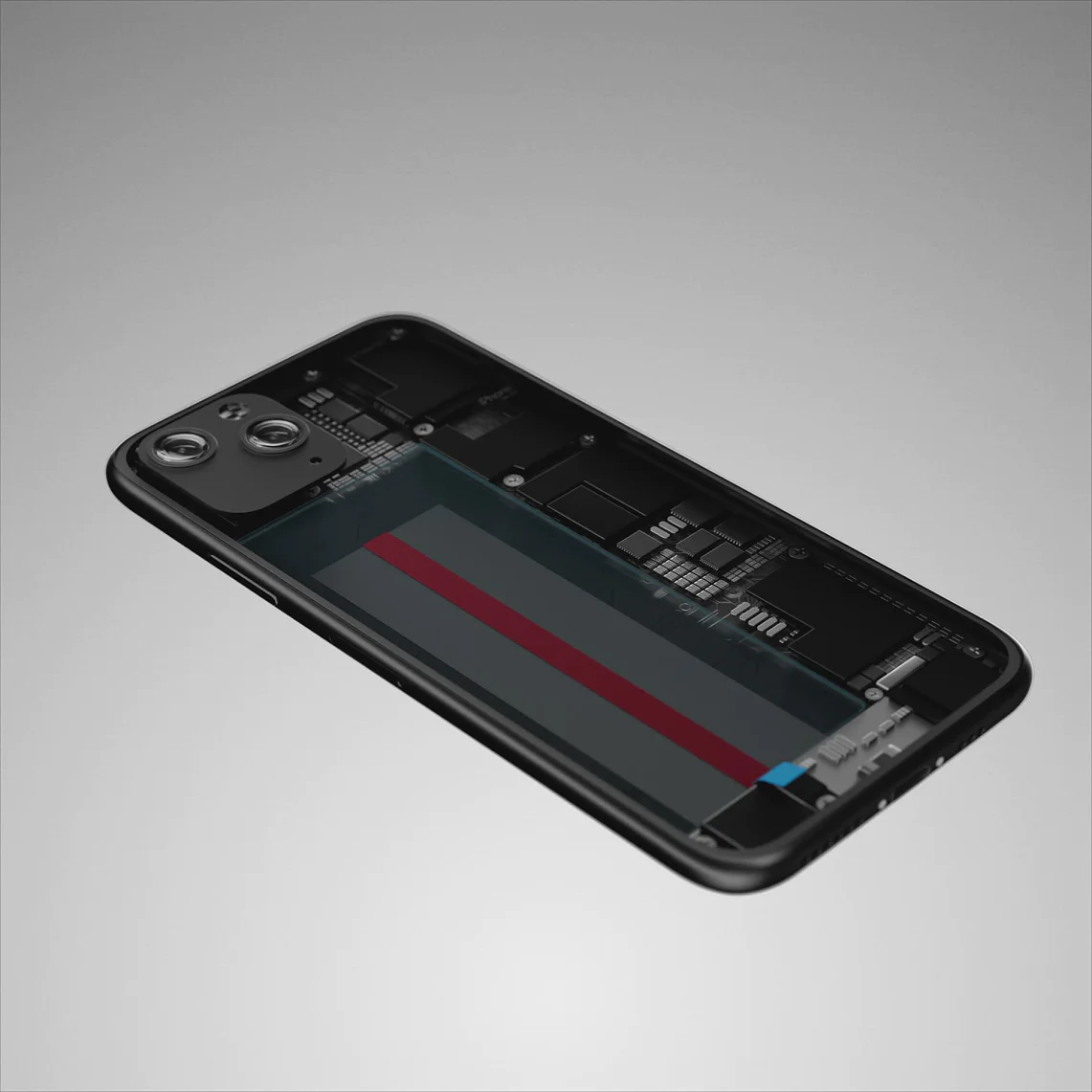

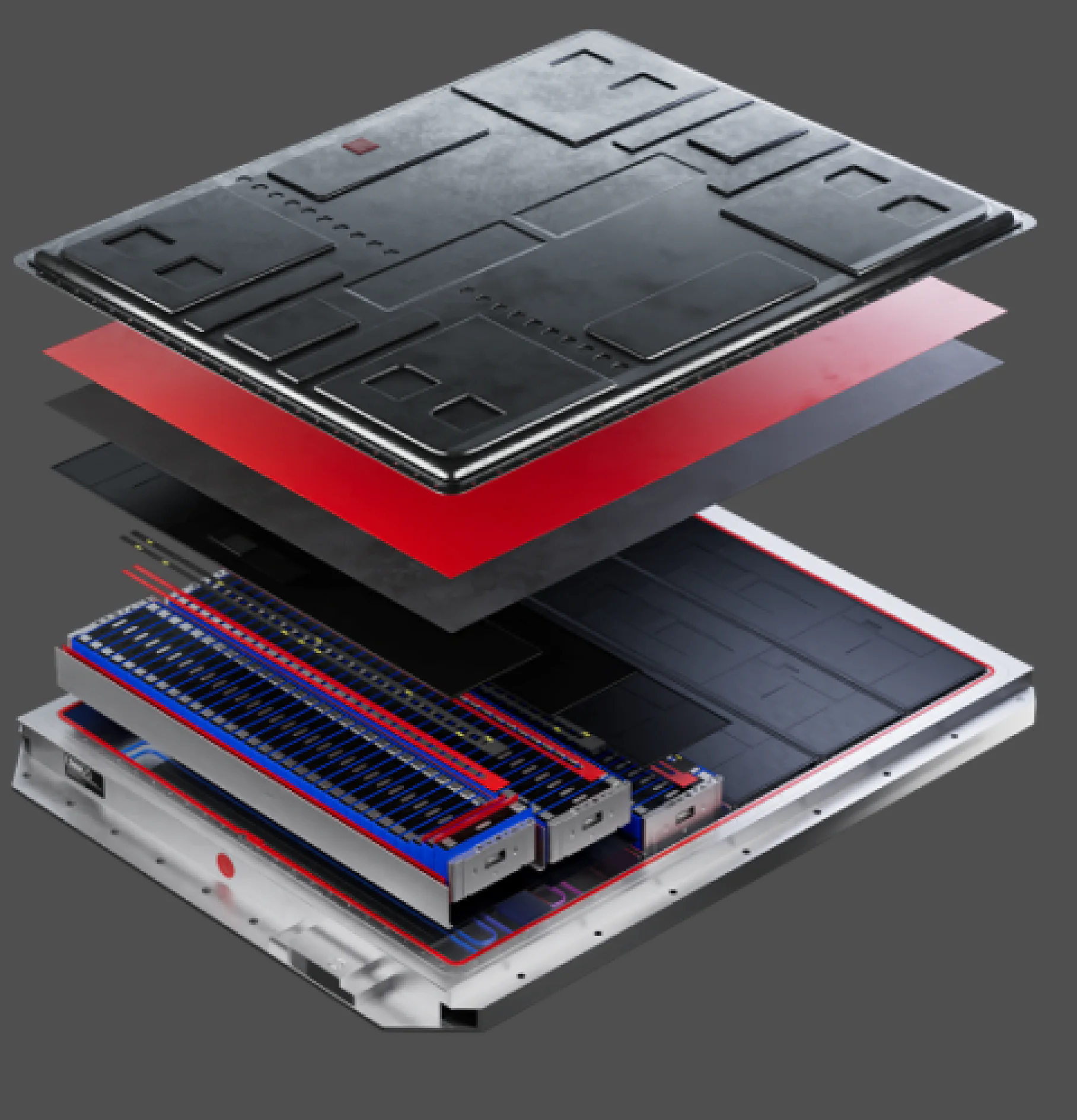

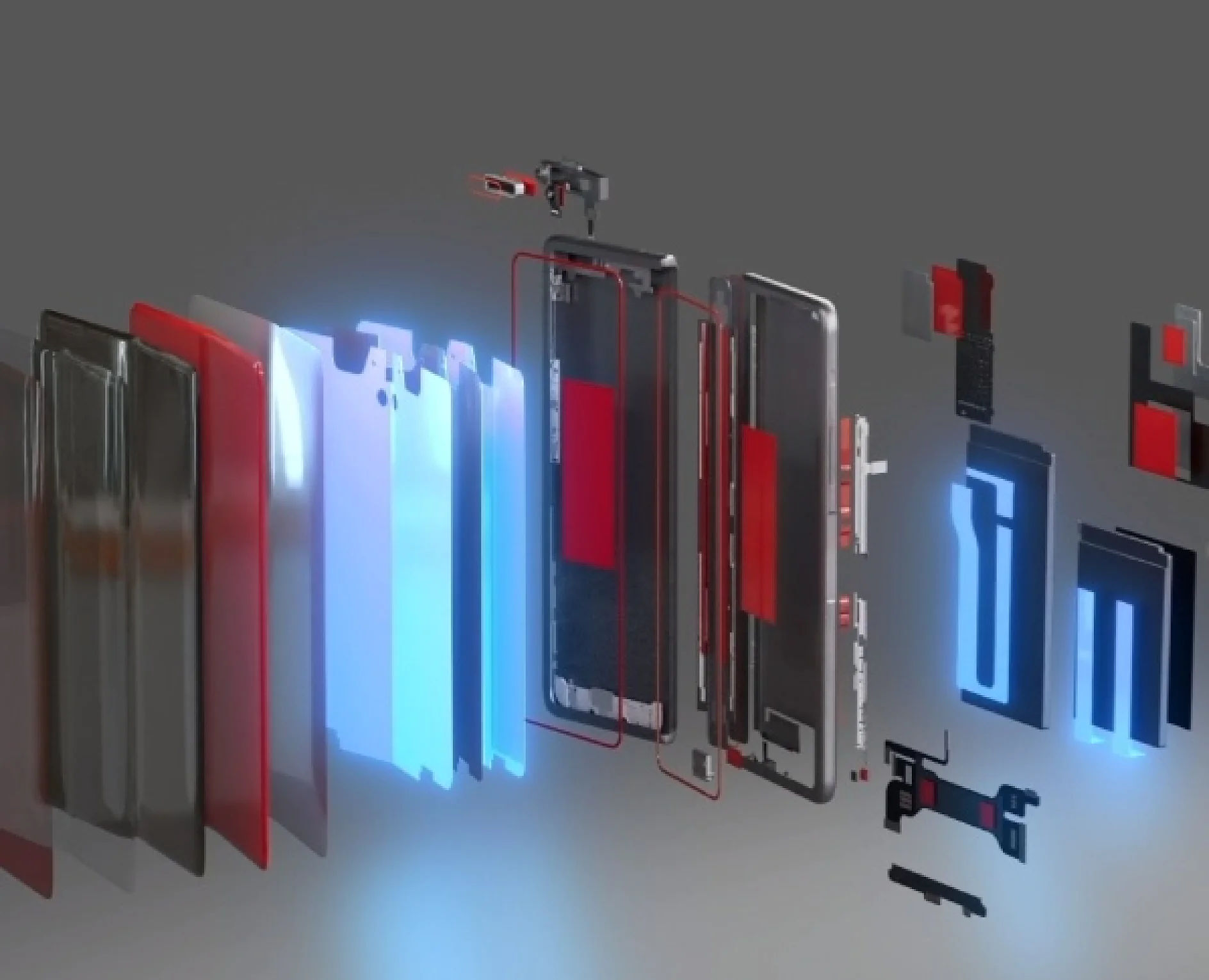

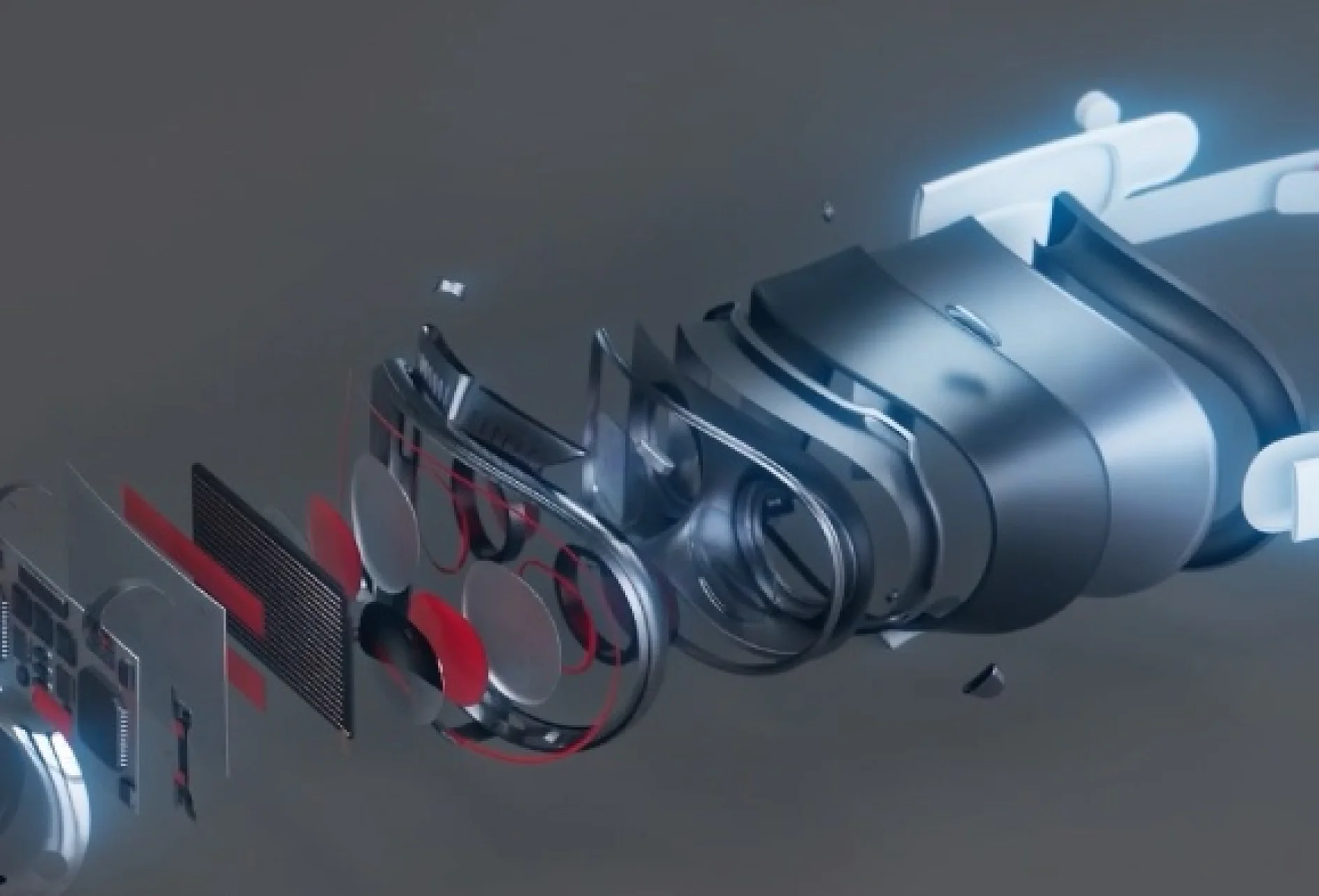

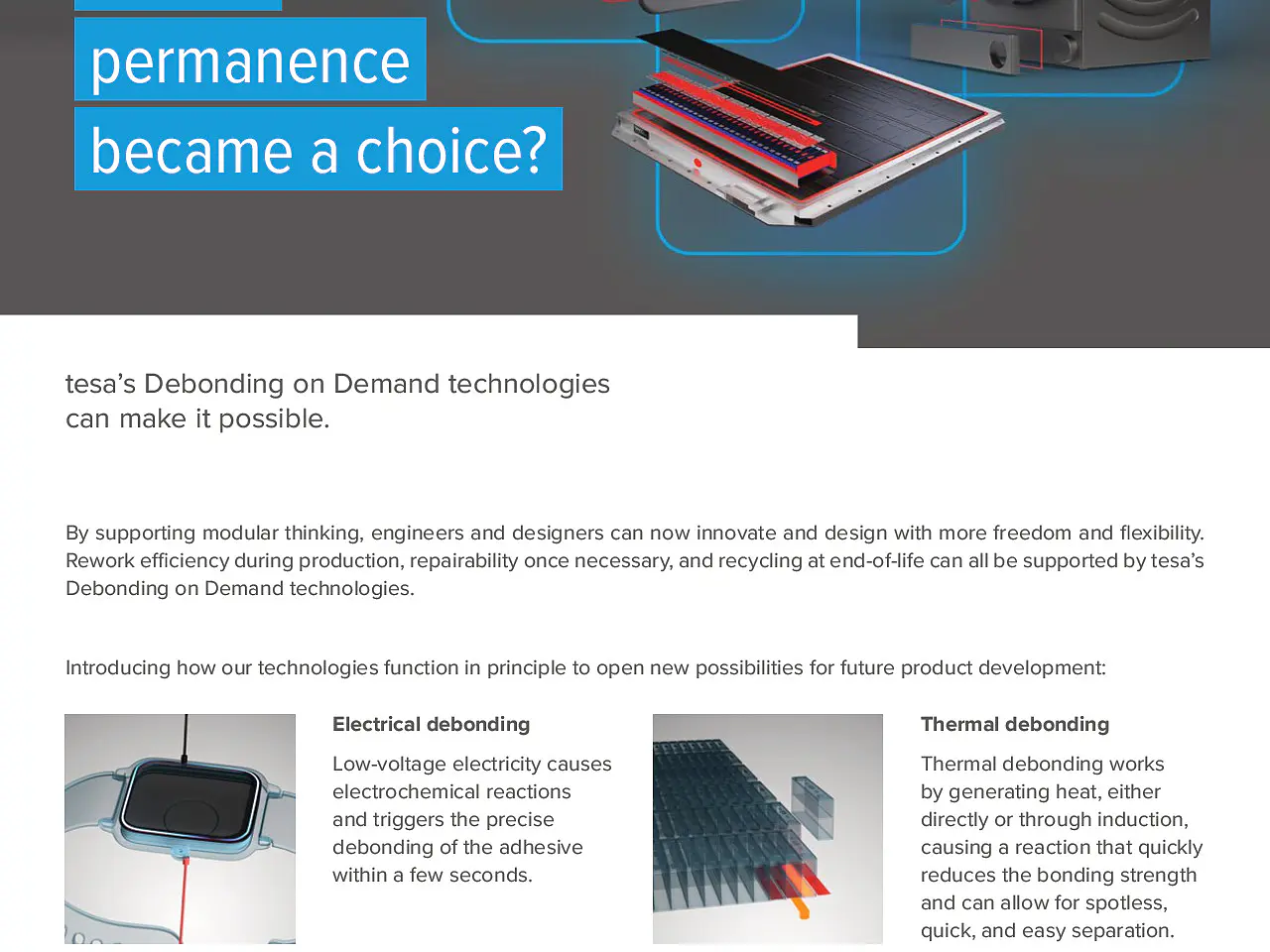

With over 125 years of experience in coating technologies and developing adhesives, bonding is our expertise. Now, we're taking this expertise to the next level by developing innovative solutions that can be precisely separated when needed – without damage to components or materials.

A game-changer shaping the future

Debonding on Demand is more than just new adhesive technology – it is a paradigm shift and will reshape entire industries and drive sustainable innovation. Debonding on Demand will enable manufacturers to create strong bonds and intentional release when needed, opening new perspectives for modern product design and sustainability.