Powering

collaboration

Advancing EV together

At tesa, we believe in progress through partnership. Working together, we can ensure that the pace of transformation continues across EV battery design. Collaborating with you on creating future proof adhesive solutions drives innovation, opportunity, and development of your products and processes.

A global business with local partnerships

As a global business, we have access to the latest EV technology and an understanding of current and future trends for EV battery production. We appreciate the value of local relationships and offer development, production and support for our customers all around the globe. Wherever you are, this local and global mix ensures benefits including short supply chains, on-site consultations and local co-development.

Applications at every stage

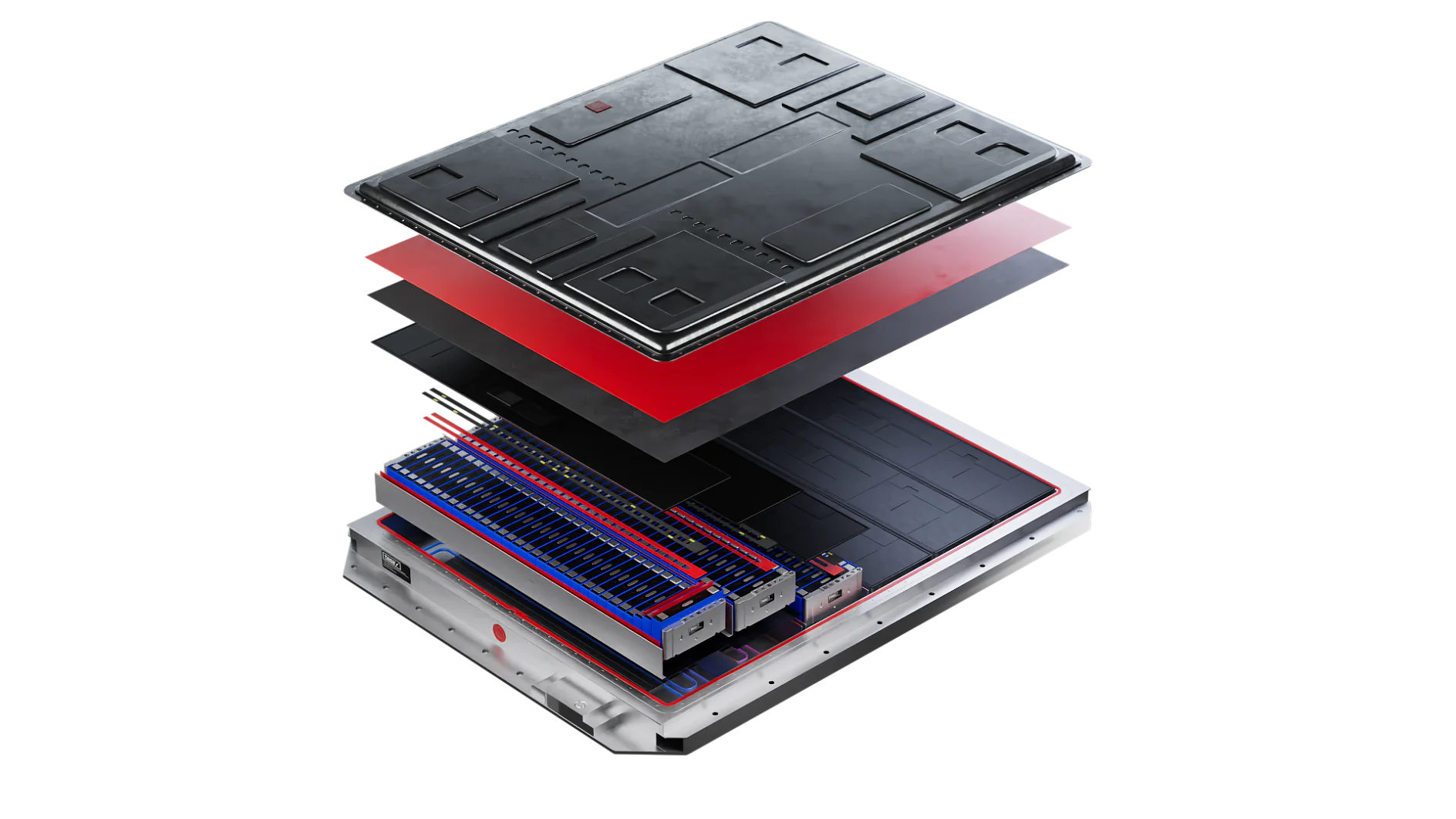

Our range of high-performance tapes has been developed with an awareness of EV battery market trends, incorporating properties to meet specific requirements inside and around the battery. As partners, we collaborate on developing products and processes that improve your existing battery and cell designs or support new innovations. In everything from structural cell wrapping tapes to adhesive patches for battery venting, we advance with you.

Experienced collaborators

A cell manufacturer that we worked with benefited from our expertise across adhesive solutions, production, and project management. We worked closely with them to provide solutions for stack fixation and cell wrapping. By monitoring their exact requirements for thermal resistance and electrical insulation closely, we were able to adapt and develop a new adhesive solution that met their needs. Advising on automating the application, we also reduced production time and resources. In addition, we were able to share decades of expertise to support other areas of the company’s project management and growth.

FIND OUT MORE

Transforming EV together

We also work with system integrators to improve application processes. For example, through a unique collaboration with specialists Liebherr and Vulkan Technic, we have developed an automated adhesive solution for battery sealing. By combining our products and expertise, together we simplified battery production and created a single, simple solution. The tesa® ACX 76730 Box Seal was produced with automation and flexibility in mind. Along with clean and reliable sealing of battery packs, it’s now also possible to rework or repair the battery pack without any issues. Watch to find out more.

Why we believe working together, works better

Nils Utesch, Head of Product Development Automotive, explains how working together creates diversity of thought and leads to more effective problemsolving solutions.