tesa® ProSeal makes automated hole covering

more efficient

Markets

Our adhesive solutions for sealing holes in the car body have proven themselves on the market for years. With tesa® ProSeal, the automated application process is now even more efficient and sustainable.

When is the right time to introduce a new, more efficient technology into the production process?

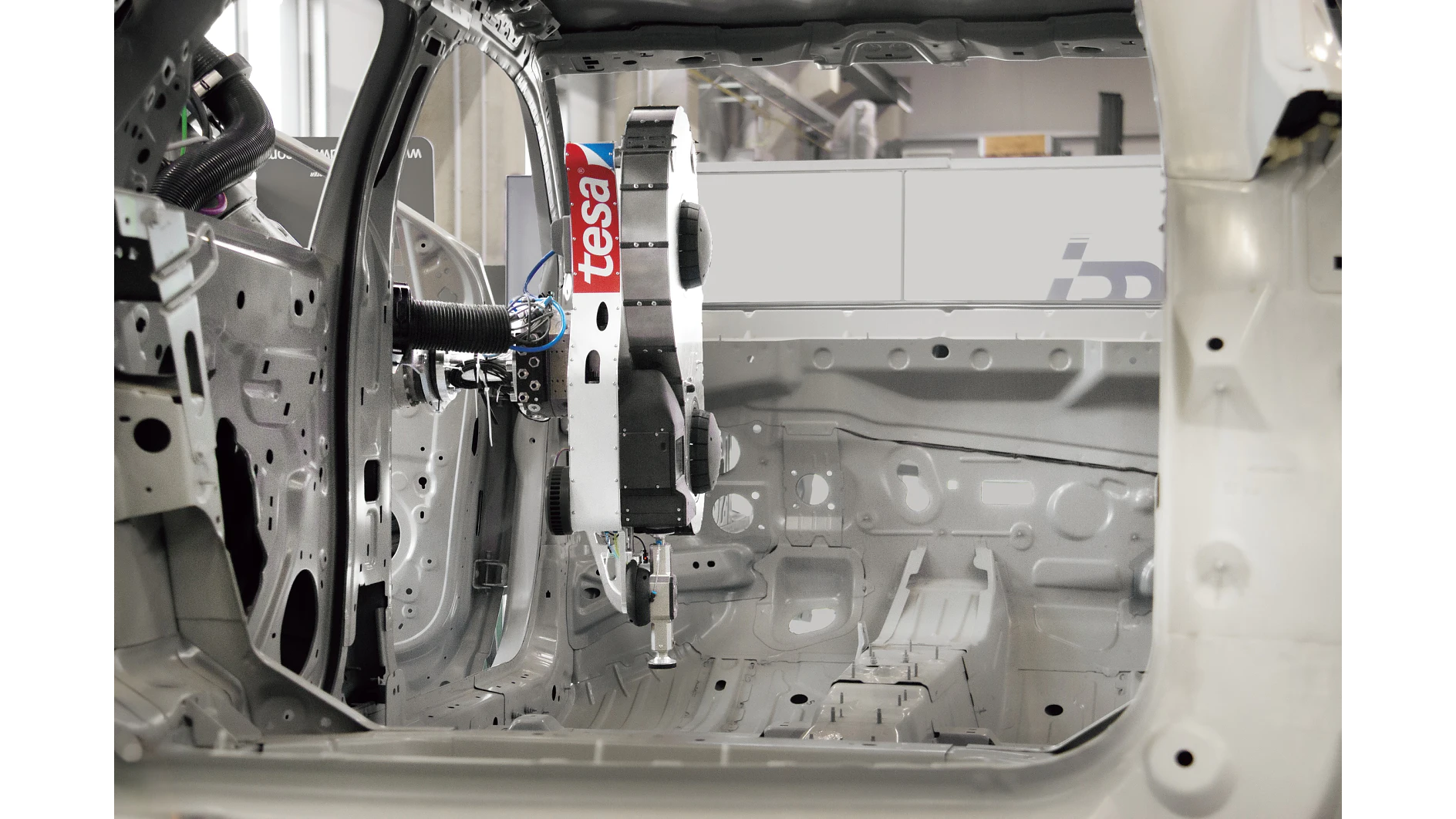

In the automotive industry, this opportunity often arises when the start of production (SOP) for a new battery electric vehicle (BEV) are being drawn up. At this stage, repetitive, error-prone tasks such as sealing holes are high on the automation wish list. With tesa® ProSeal, an application technology is now available that enables greater efficiency and cost effectiveness without labor constraints or bottlenecks.

Car body sealing is ergonomically demanding, wages are rising, and sometimes it is difficult to retain or even find skilled labor, especially in aging societies. All these challenges can be addressed through automation. We support our customers in selecting the right, high-performance product for their specifications. And we offer them tesa® ProSeal, a fully automated hole covering cell hat increases the reliability of the process. As a result, we can achieve a line availability of more than 99 %.

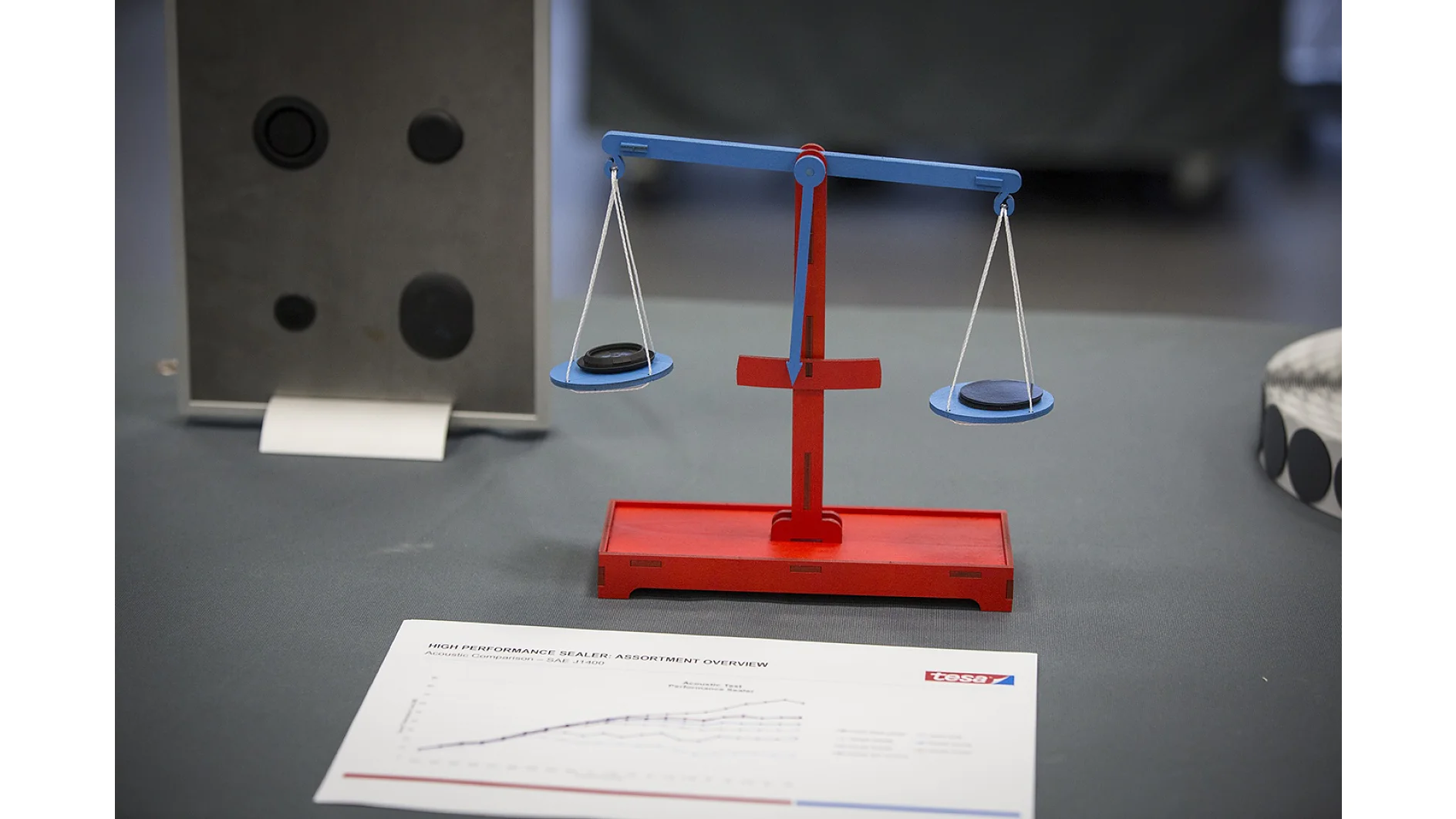

In comparison to plastic plugs tesa® adhesive solutions have clear advantages

Traditionally, holes in the car body are sealed with plastic plugs. In comparison, our adhesive solutions have a number of significant advantages:

While plastic plugs must fit exactly into the hole, our adhesive patches can cover several hole sizes, which increases the efficiency of the application process. They also require much less space: a plug can protrude up to 6 mm on the outside and up to 8 mm on the inside, while our patches have a maximum thickness of just 2 mm.

tesa® ProSeal - more efficient, more sustainable

tesa® adhesive patches consist of a functional layer made from a durable material such as PET, aluminium or cloth and an adhesive such as acrylic or natural rubber. The liner, which consists of paper or PET, is removed before application. The different materials are selected depending on the area of application and have an effect on paintability, stone chip and temperature resistance, corrosion, puncture resistance and acoustics. We offer patches for holes on the outside, inside and in the battery of the car.

With tesa® 90% PCR 54349 for exterior use, a variant with 90% post-consumer recycled (PCR) content in the backing material is available to our customers.

To make the application process as efficient as possible, tesa® ProSeal uses a die-cut cartridge system. When all the patches in a cartridge have been applied, it can be replaced within 15 seconds. The used cartridge is then returned to tesa to be refilled. This circular process reduces waste and increases sustainability.

In addition, an innovative supply chain and data management concept around the cartridge tracks the efficiency of the application and enables continuous optimisation.

Why do our customers trust tesa?

When we started developing specific products to cover holes in the car body, all adhesive patches were applied manually. We therefore set up a dedicated engineering department and created a new device for automatic application. Our first line was built together with Porsche Zuffenhausen. We now have 13 systems in operation and more are already being planned. More than 100 million holes are closed with tesa automation solutions every year.

Building on this experience, we have improved this reliable process even further. In short, tesa® ProSeal combines: