Display closing with endless tape automation

Bigger, brighter, with invisible frames: Human machine interfaces (HMI) are ubiquitous and rapidly evolving. And our adhesive tape technologies for display mounting are keeping pace.

For display frame mounting the market mainly relies on two adhesive technologies: While liquid glue is highly flexible, tape die-cuts are easier to apply and have a consistent thickness. They also create an immediate bond without curing time and without drawbacks such as oozing or clogged nozzles.

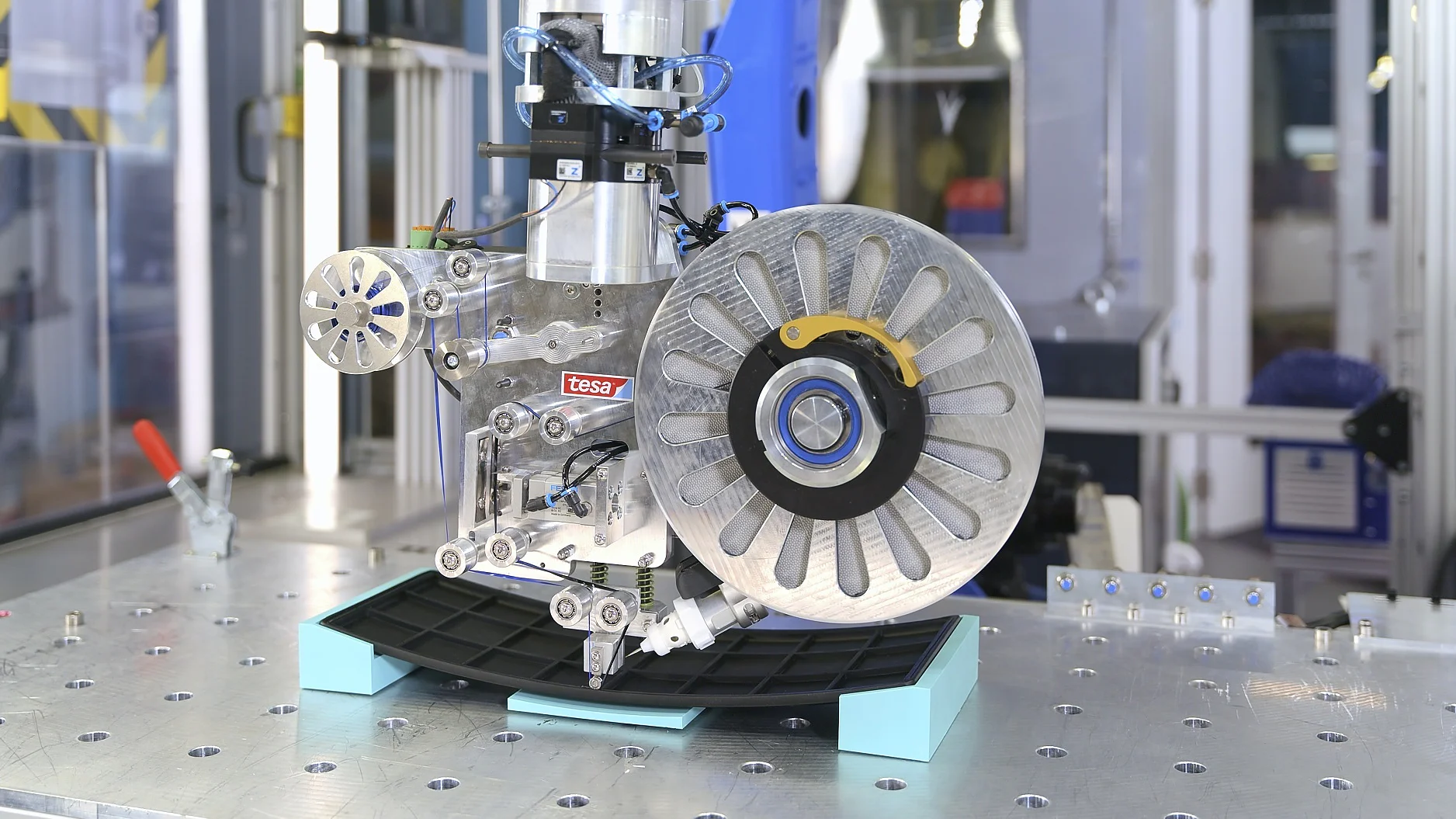

To combine the flexibility of liquid adhesives with the advantages of tape die-cuts, we have developed a new generation of adhesive tapes for automated application. tesa® ACXplus 727xx Deep Black line for display closing is a very narrow endless tape that is applied automatically with spools. This innovative technology is ideal for displays with narrow boarders and can achieve more sophisticated designs than liquid adhesives. It is easier to set up, eliminates die-cut waste and is very cost effective.

Our new automatic spools with 2 mm endless tapes combine the advantages of both technologies commonly used for narrow boarder mounting: liquid glue and adhesve tape die-cuts.

Advantages of spooling automation for display closing

- Strong bonding for narrow frames

- Total cost saving

- Robust, fully automated process

- Continuous production due to endless application with spools

- Low maintenance of application devices

- Removable tape for rework if necessary

Our 2 mm endless tapes are easy to integrate into the production process

- Compared to liquid application, equipment investment is low.

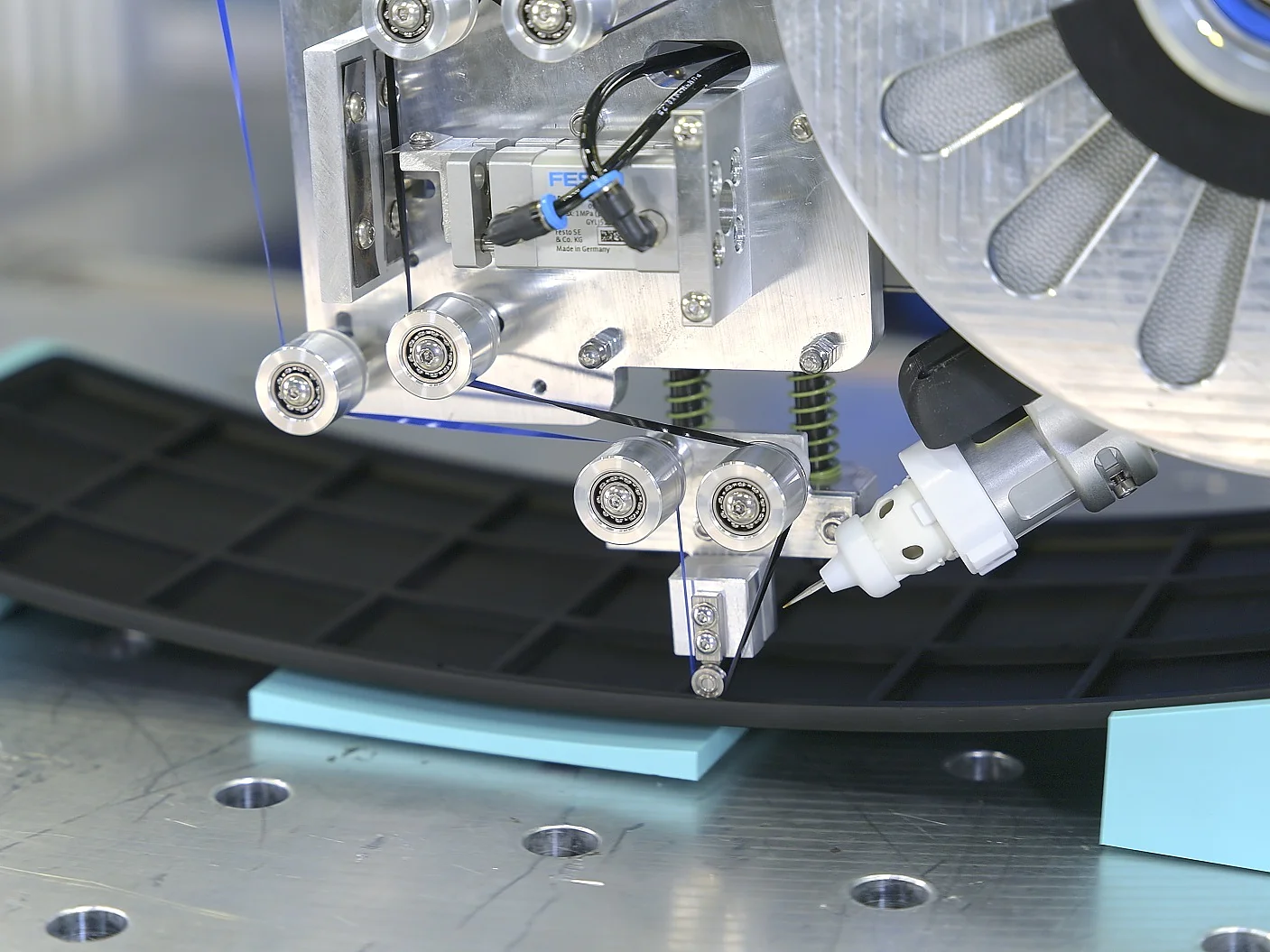

- The application head weighs less than 20 kg, including a high precision cutting unit, and can run at speeds of 200 mm/sec without stretching.

- The tape is fed from a spool of up to 2,000 m, reducing spool changes to one per shift.

Adhesive tapes also require fewer jigs, no batch clamping or curing, and production waste is significantly reduced because the tapes can be removed for easy and clean rework if necessary. Another advantage is that there are no open time limits – and downtime is not a problem, either. Even storage and disposal are easier as there are no drums of liquid adhesive.

In the production of narrow boarder designs, adhesive tapes offer strong bonding and very good control of dimension tolerances. Tapes ensure tickness and width consistency and simultaneously increase design freedom: The high flexibility of our adhesive tapes allows for extremely narrow curves with radii as small as 2 mm, reducing the need for cutting and the risk of leakage.

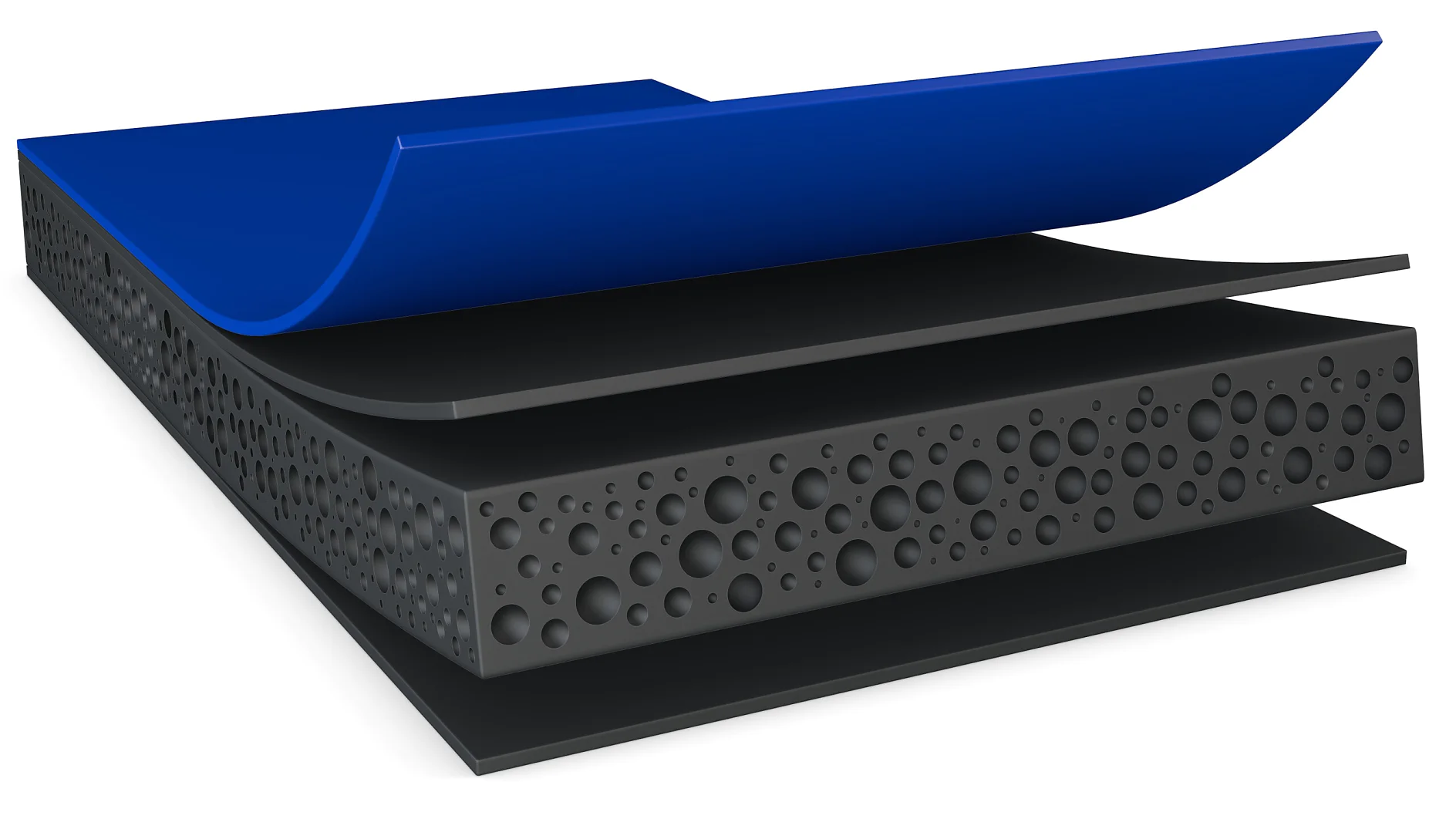

Characteristics of tesa® ACXplus 727xx Deep Black

- Deep black colour

- Light blocking in all directions

- Compatible with (L)OCAs – no change in visual properties (DIN 75220)

- Shear resistant

- Closed cell acrylic foam for secure sealing

- Viscoelasticity compensates for thermal expansion and other types of stress

tesa® 727xx Deep Black performance characteristics

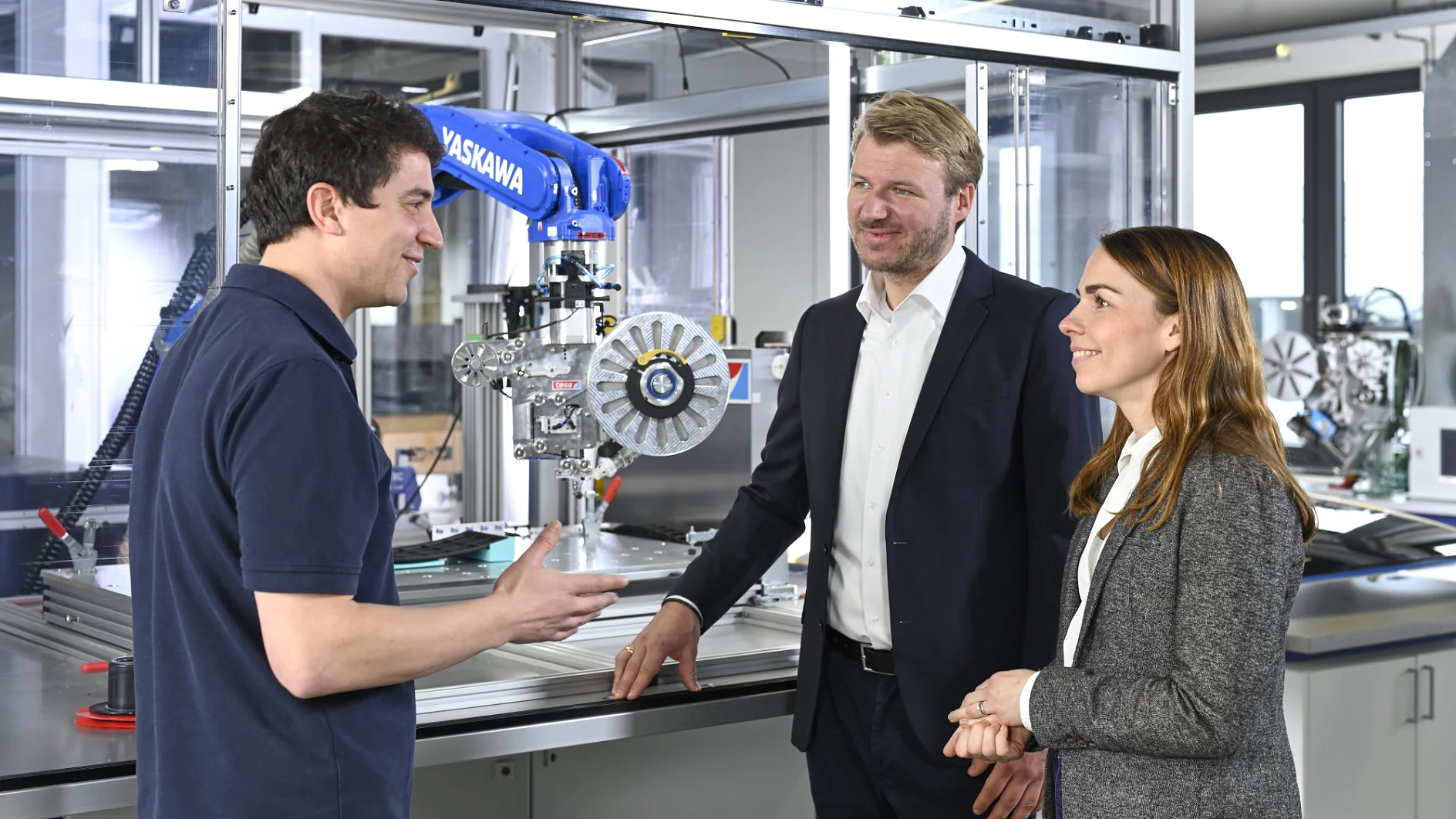

Trust our experience in demanding industries

At tesa, we have extensive experience in the electronics and automotive industries. Our adhesive solutions are used in more than 200 automotive applications, making cars smarter and lighter – an important contribution to more sustainability. We are also the market leader in Debonding on Demand technologies that enable rework, repair, and recycling. tesa® Bond & Detach products are found in more than 1.5 billion smartphones worldwide.