Technologies

Producing state-of-the-art battery packs becomes easier and more efficient with our new UV-activated structural tape.

Over the next decade, a revolution will take place in the automotive industry. Some major markets and even car manufacturers have already set dates for the phase-out of internal combustion engines. In the EU1 and California2, all new cars have to be emission-free by 2035. In addition, an average battery price of $100 per kWh, often considered the threshold for price parity between electric and conventional vehicles, is expected to be reached in the next few years3.

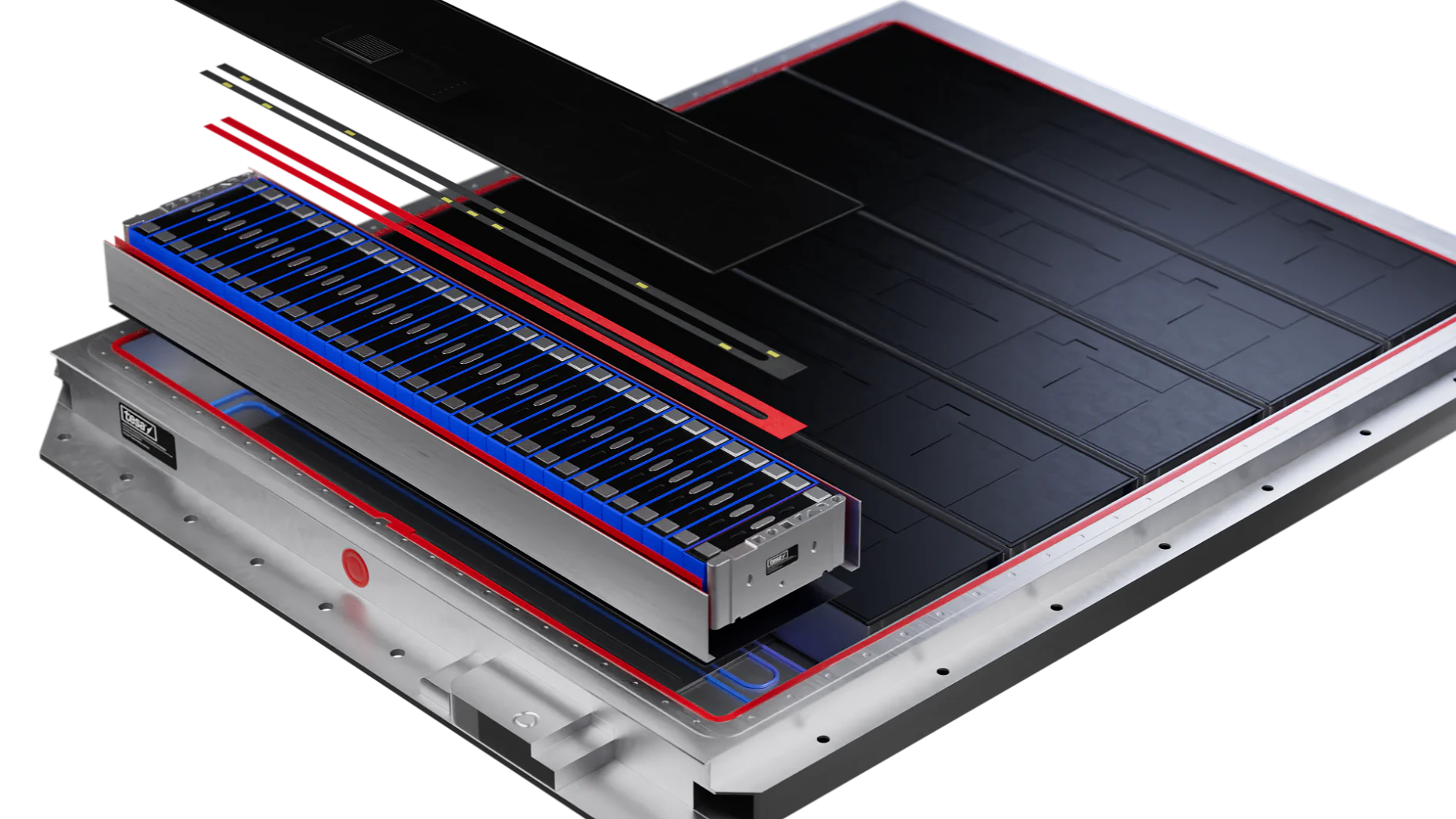

At tesa, we are actively supporting this transformation towards a more sustainable mobility. Among other things, we are working with the industry to increase the energy density of battery packs and thus the range of electric vehicles. With our new product tesa® 58655 structural electrical insulation tape, cutting-edge battery cell manufacturers can use cell-to-pack and cell-to-chassis designs to achieve a 72% higher volume utilization efficiency.

Let's explain what that means.

Cell-wrapping with UV epoxy tape

A traditional automotive battery architecture has three layers. The battery pack contains a number of modules, and each module itself contains a number of cells in which energy is stored. This structure makes it possible, at least in theory, to replace defective modules. But the design also has a significant drawback: Because each module needs a mechanical structure, only about half of the battery pack consists of active material, the cathodes and anodes that store electricity. The other half is made up of metal, plastic, insulating materials, electronics, and other components.

To make better use of the available space, advanced battery designs skip the module layer and integrate the cells directly into the battery pack or even the vehicle chassis. Of course, the cell-to-pack and cell-to-chassis designs must conform to the same safety and reliability standards as the traditional architecture. Therefore, the wrapping solutions must ensure that each cell is part of the structure, which increases the requirements for the mechanical properties of the adhesive tape while providing protection against dielectric breakdown. For this set of requirements, we have developed a superior tape solution.

Application of tesa® 58655 structural electrical insulation

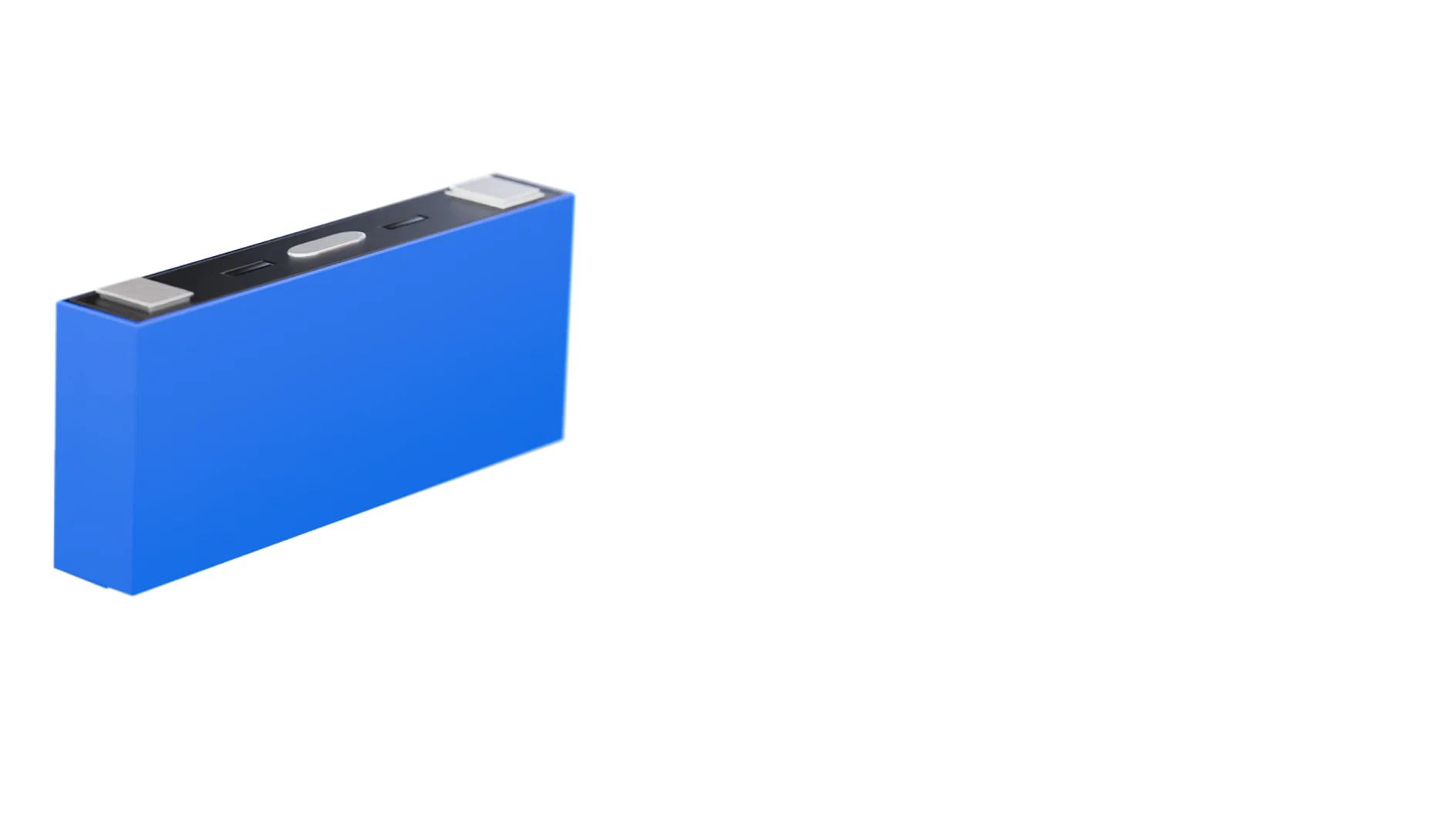

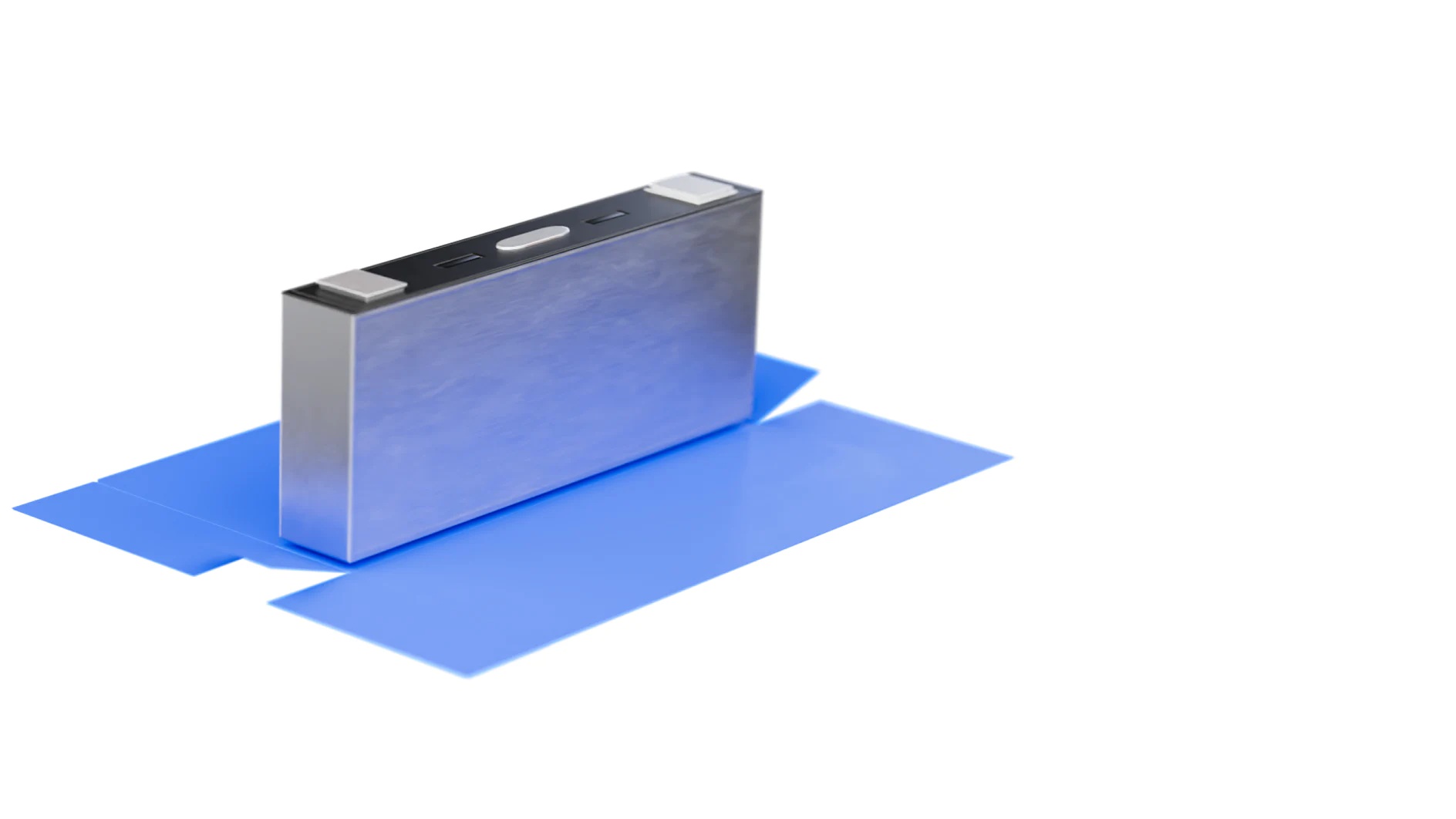

tesa® 58655 structural electrical insulation is a UV curing tape for cell wrapping. It consists of a PET backing, a UV-activated adhesive and a PET liner. Each layer is only 50 µm thick. The adhesive can be activated before or after the tape is applied, allowing for flexible production processes.

Automated cell wrapping

1https://www.bmuv.de/en/pressrelease/eu-member-states-pave-way-for-zero-emission-cars-from-2035

2https://theicct.org/growing-momentum-global-overview-of-government-targets-for-phasing-out-sales-of-new-internal-combustion-engine-vehicles/

3https://about.bnef.com/blog/increase-in-battery-prices-could-affect-ev-progress/