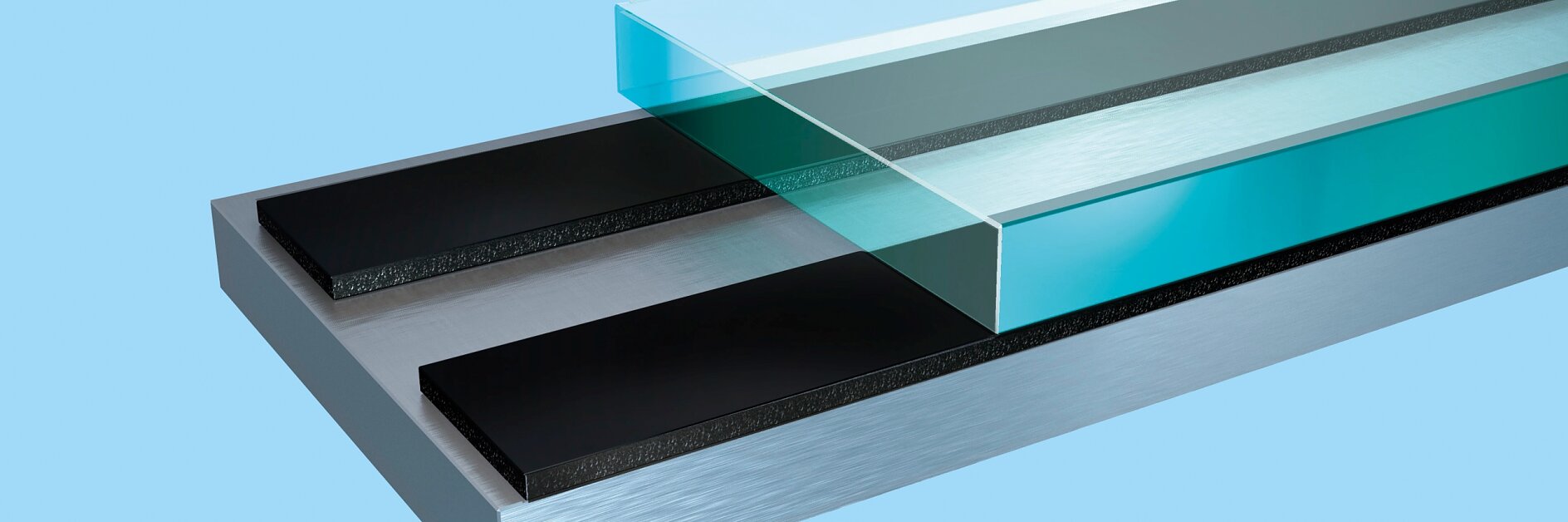

Advantages of Double-Sided Adhesive Tapes

There are many reasons that speak in favour the use of double-sided adhesive tape: Freedom of design, quality of the bond, and the assembly process to name a few.

There are many reasons that speak in favour the use of double-sided adhesive tape: Freedom of design, quality of the bond, and the assembly process to name a few.

There are many reasons that speak for the use of double-sided adhesive tape. The freedom of design and the clean working method are just two examples. However, the true advantages of these tapes become particularly clear if you compare double-sided adhesive tapes with other mounting methods.

Therefore, we have developed a transparent rating system that shows you the strengths and weaknesses of different mounting methods at a glance. In our rating, we compare double-sided adhesive tapes with liquid glues and mechanical mounting systems.

In order to achieve maximum transparency, we’ve compared the mounting systems not only in terms of the three main mounting characteristics – quality, assembly and design – but we have also subdivided these features to show exactly what is important when mounting an object.

Not all quality criteria are equally important for all possible applications. Therefore, it is useful to closely consider and evaluate the quality criteria with regard to the desired application.

Our evaluation criteria for adhesion quality are as follows:

| Double-sided tapes | Liquid glue | Mechanical fastening | |

|---|---|---|---|

| Compensation of irregular or uneven surfaces – gaps between bonded surfaces are eliminated | +++ | ++++ | + |

| Compensation of tension and stress dissipation – single bonding point with mechanical fasteners can lead to material breakage | ++++ | ++ | + |

| Shock absorption | ++++ | ++ | ++ |

| Reduced risk of corrosion | ++++ | ++++ | + |

| Sealing function – tape seals and protects against dust and moisture | ++++ | ++++ | ++ |

| Noise-dampening properties – sounds caused by vibration are eliminated | ++++ | +++ | + |

Processing and assembly with double-sided tape offer significant advantages in terms of a clean and healthy production process.

Our evaluation criteria for assembly are as follows:

| Double-sided tapes | Liquid glue | Mechanical fastening | |

|---|---|---|---|

| Fast application process – elimination of curing time and reduction of complexity | 4 | 1 | 2 |

| Healthy working environment and clean production sites | 4 | 2 | 2 |

Mounting solutions should not collide with the freedom of design. Therefore, design is a criterion of considerable importance in the evaluation of different mounting solutions.

Our evaluation criteria for design are as follows:

| Double-Sided Tapes | Liquid Glue | Mechanical Fastening | |

|---|---|---|---|

| Improved visual appearance – no damage to the material | ++++ | +++ | + |

| Invisible fastening – mounting of transparent materials | ++++ | +++ | + |

Quality

Quality

Assembly

Assembly

Design

Design

Quality

Quality

Quality

Quality