Electrically conductive tapes

for industry

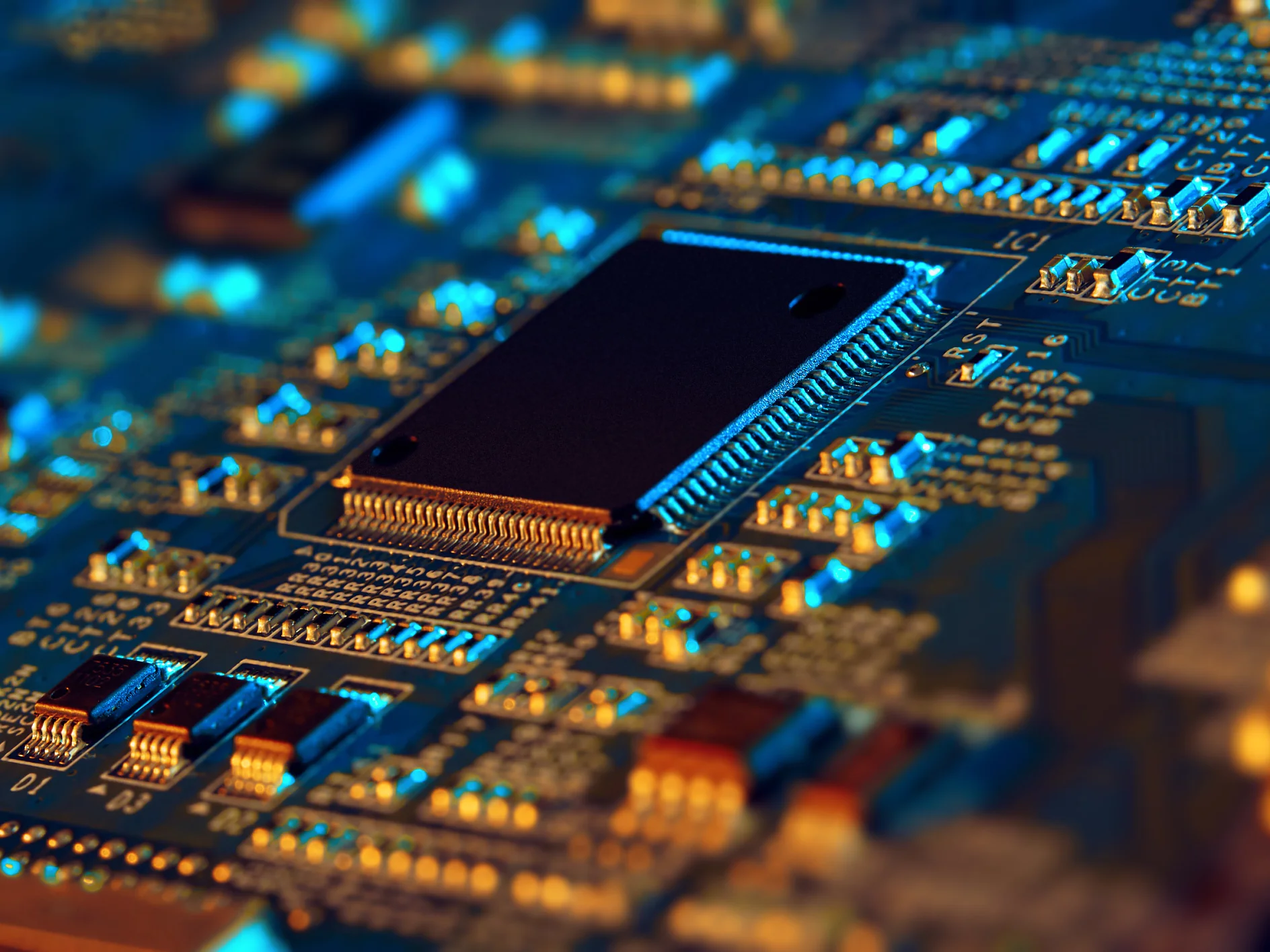

Our electrically conductive adhesive tape can be used widely in industry applications that demand reliable adhesion with electrical conduction. The performance of our pressure sensitive conductive tapes is backed by our reputation and decades of experience. They are high-performing and easy to integrate into the manufacturing process. These adhesive solutions are suitable for use in applications where effective conduction, grounding, or shielding is essential.

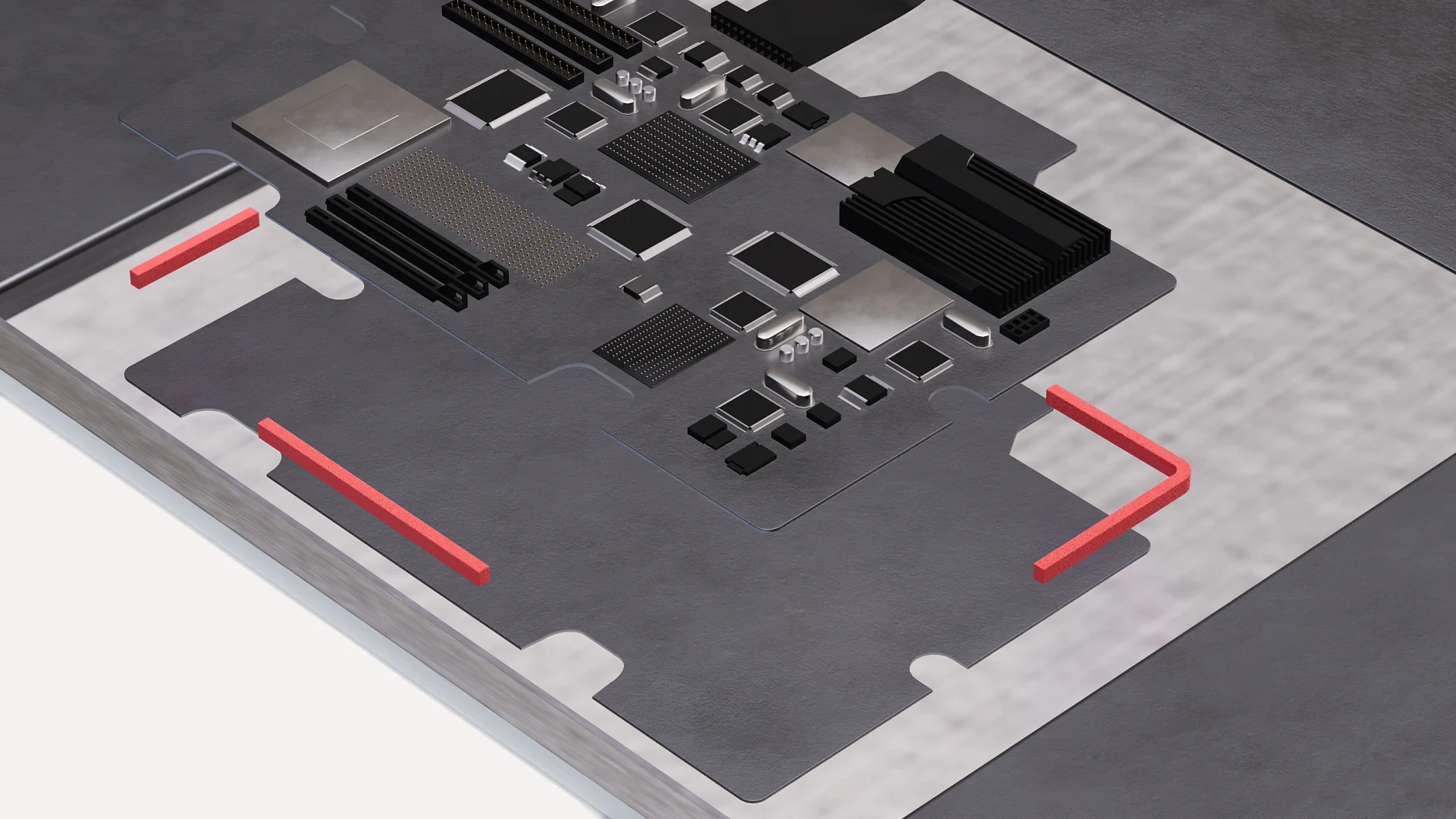

At tesa we have developed electrically conductive adhesive tapes for many industrial applications, including automotive and electronics. Single-sided tapes are widely used for applications such as bonding, sealing, and electromagnetic shielding. Double-sided tapes play a key role, for example, in the assembly of electronic equipment, for mounting and grounding.

Key features of our industrial conductive tapes

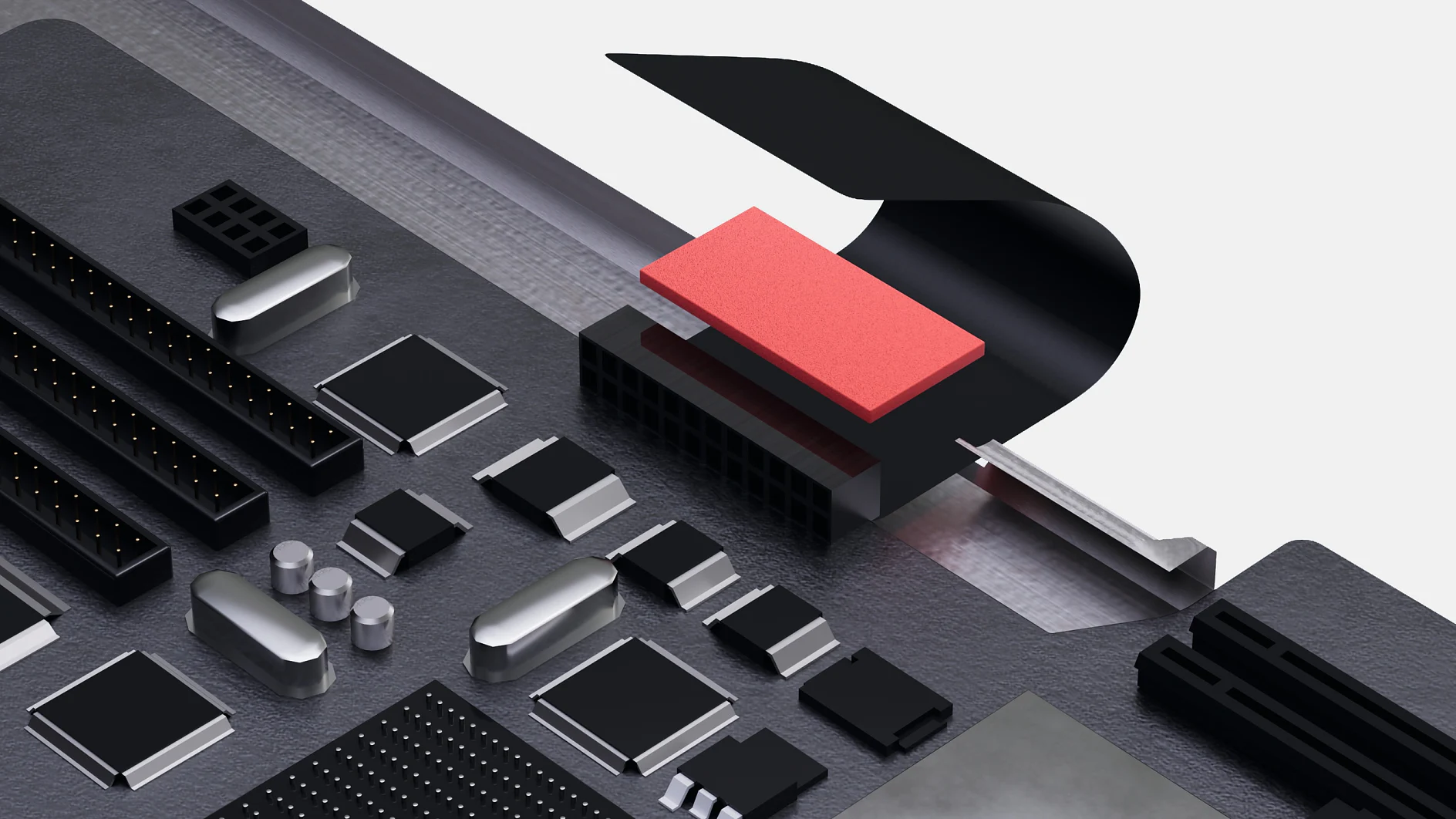

Our tapes combine conductive acrylic adhesive with a choice of conductive backings: Foam, woven, and non-woven, fabric, aluminum, and copper. They are robust and versatile, and come in a variety of thicknesses ranging from 17 µm to 2,000 µm. Electrically conductive tapes are available with XYZ axis conductivity (conducts through length, width, and thickness of the tape) and XY conductivity (does not conduct through the thickness of the tape) for conductivity and insulation, according to your intended application.

If you require supplemental information about the choice of conductive tape for your project,

Typical industry applications for electrically conductive tape

Electrically conductive tape has a variety of industrial applications where reliable conductivity needs to be balanced with effective adhesion. It is widely used in automotive manufacturing processes and the assembly of electronic devices. Our conductive adhesive tapes are designed to meet different requirements and environmental conditions for effective conduction, grounding and shielding in electrical applications.

Typical applications include:

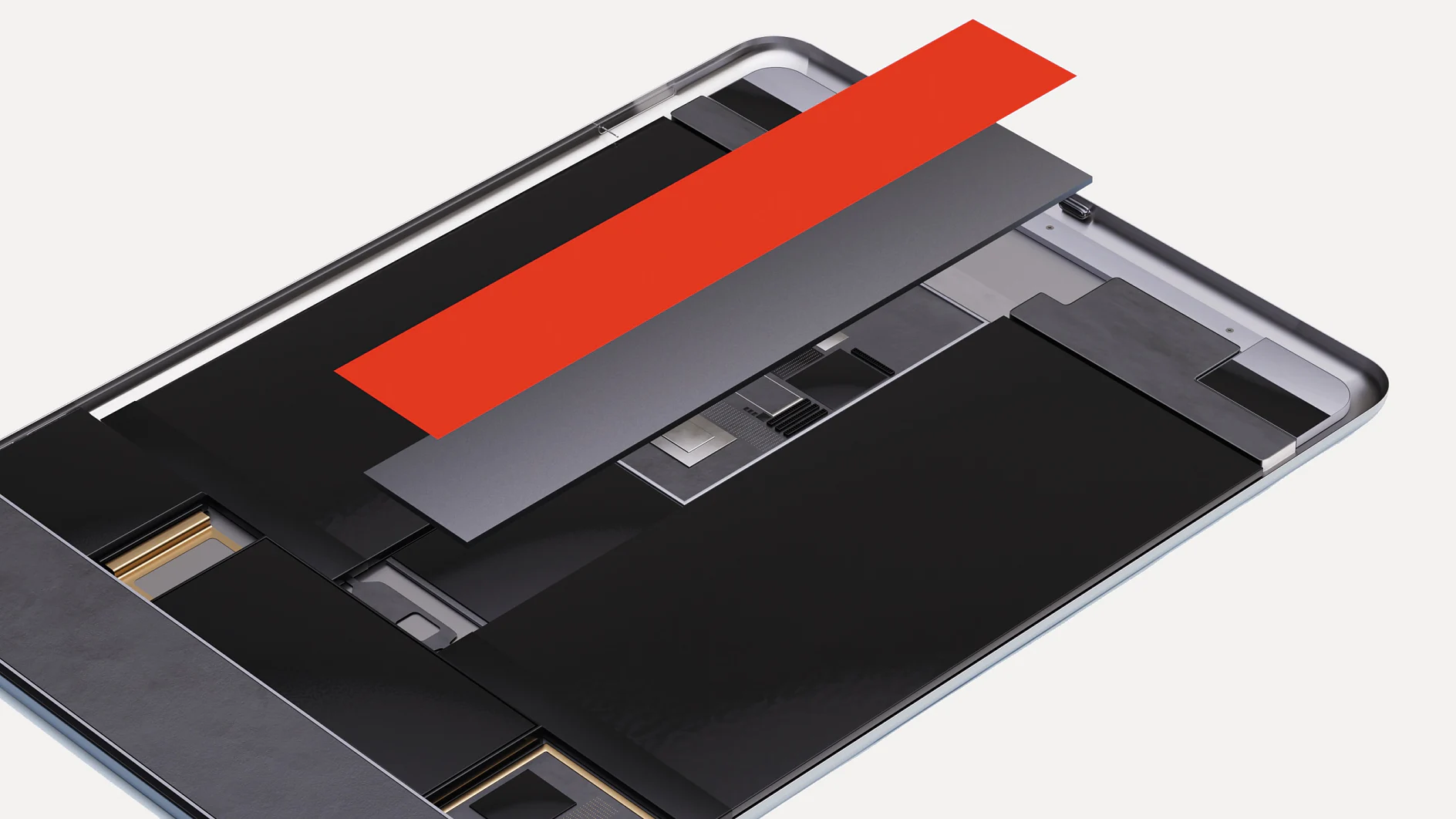

- Electrical conductivity: Our conductive tapes facilitate the transfer of electrical signals between individual pieces of equipment, surfaces, or components, for example in the production of display screens.

- Grounding: Maintain safety and prevent electric shocks by establishing a reliable connection between conductive components or surfaces.

- EMI shielding: Used throughout the electronics and telecommunications industries for sealing and gap-filling to protect sensitive components from electromagnetic interference.

- Preventing electronic static discharge (ESD), which may cause damage to electronic devices with sensitive components.

If you need additional information or have a query about suitable products for your application,

Conductive tapes for industrial applications

At tesa, our conductive tape solutions offer you the highest quality, electrical conductivity and performance for your applications. Find an overview of our conductive double-sided, single-sided and foam tape solutions below: