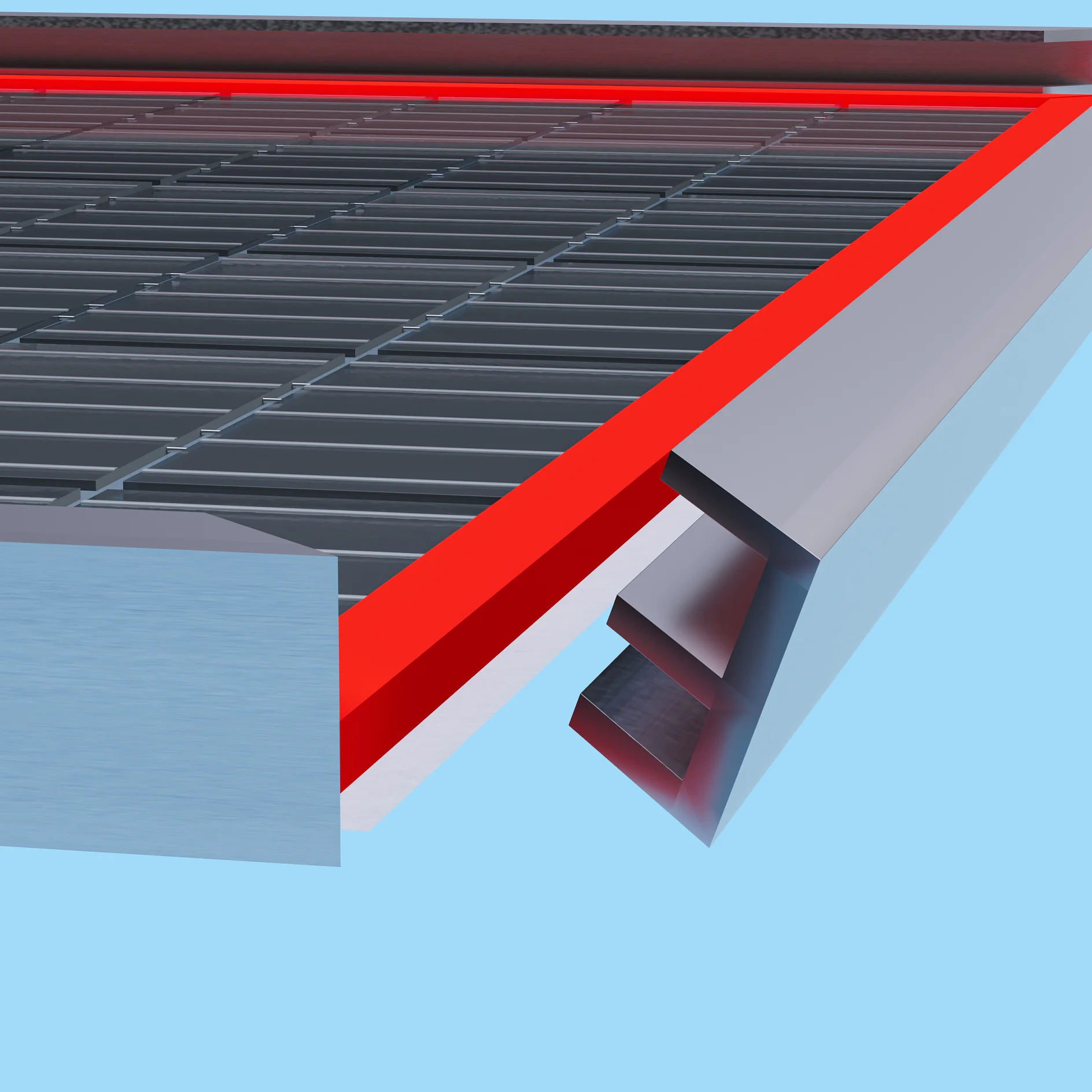

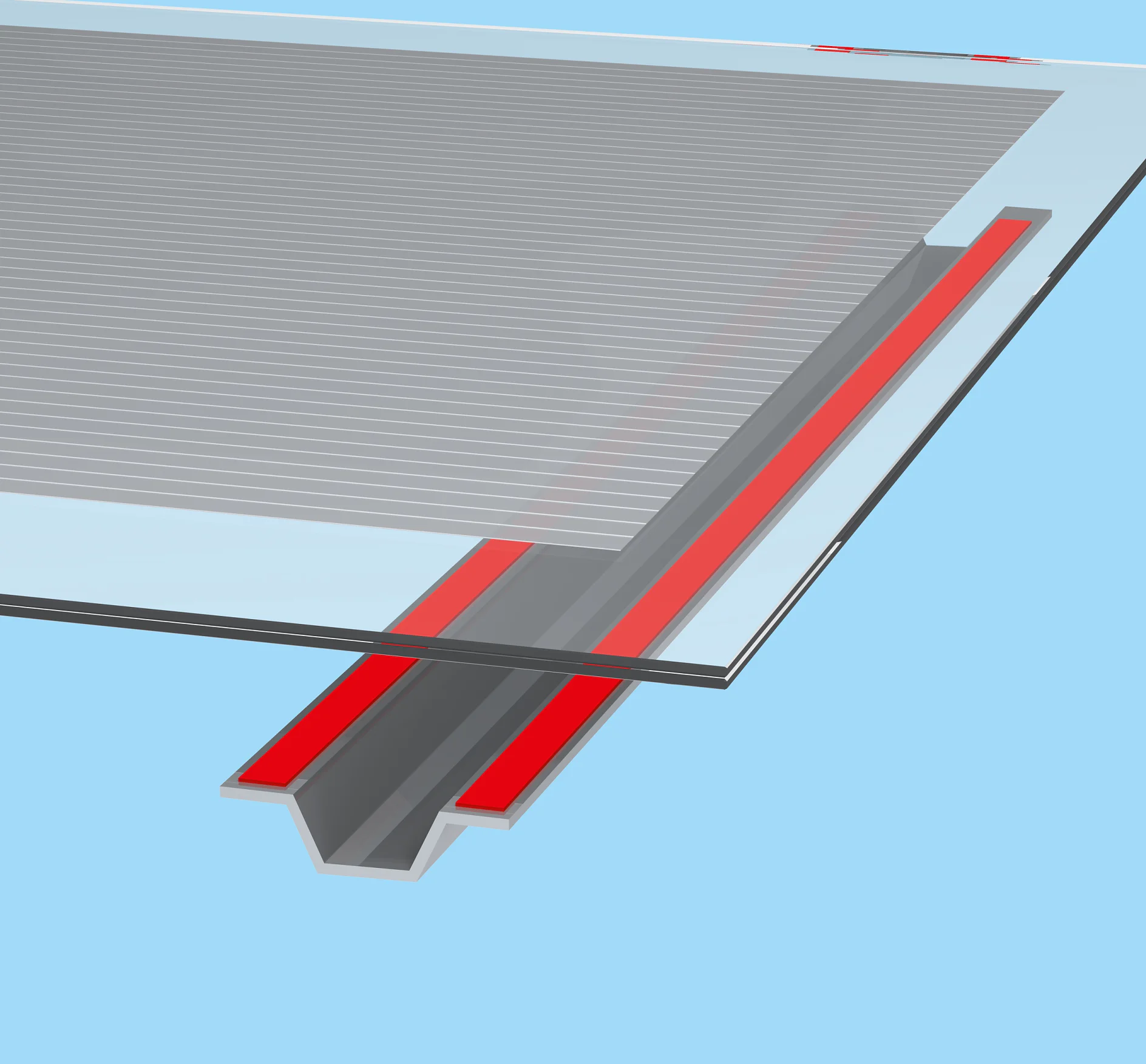

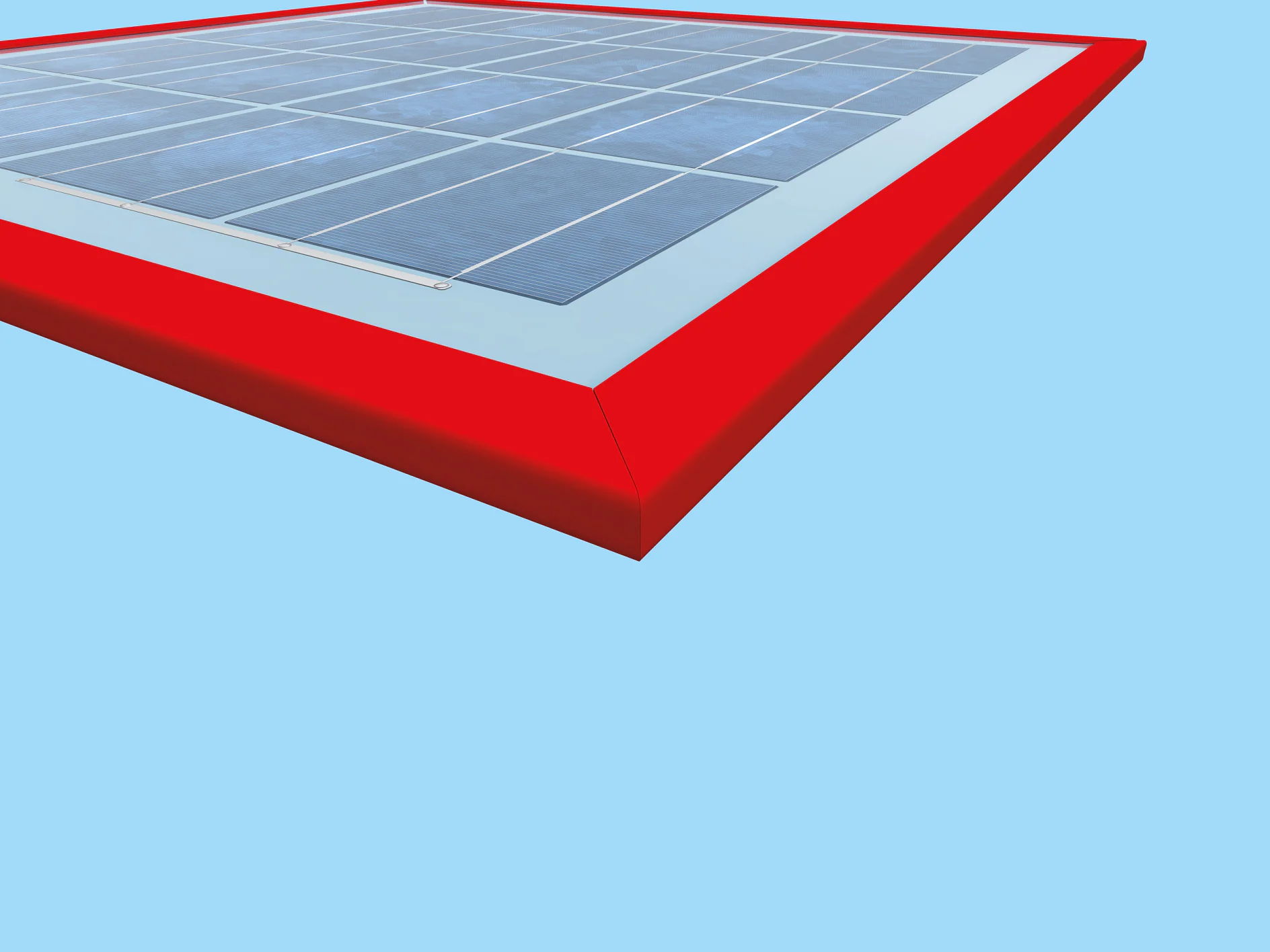

Mounting PV cells onto frames requires an assembly solution which provides a reliable, durable bond and weatherproof seal. Our high-quality solar panel adhesive tapes, tesa® 62510 (opens in a new window or tab) double coated PE foam tapes, are favored by manufacturers for simplifying solar module assembly thanks to their high ultimate adhesion levels and inner strength. And of course, both tapes are engineered for outdoor use thanks to their UV, water, and age resistance.