Our advanced shielding tapes

protect vital electrical equipment

The electronics industry continues to innovate at lightning speed. Devices like smartphones and laptops are becoming smaller, thinner, and more streamlined. And household appliances and car systems now incorporate advanced features and complex functionalities. With consumers’ increasing dependence on these devices, you as manufacturers are under constant pressure to deliver innovative products while maintaining quality and performance. A key aspect of this is shielding components from electromagnetic interference.

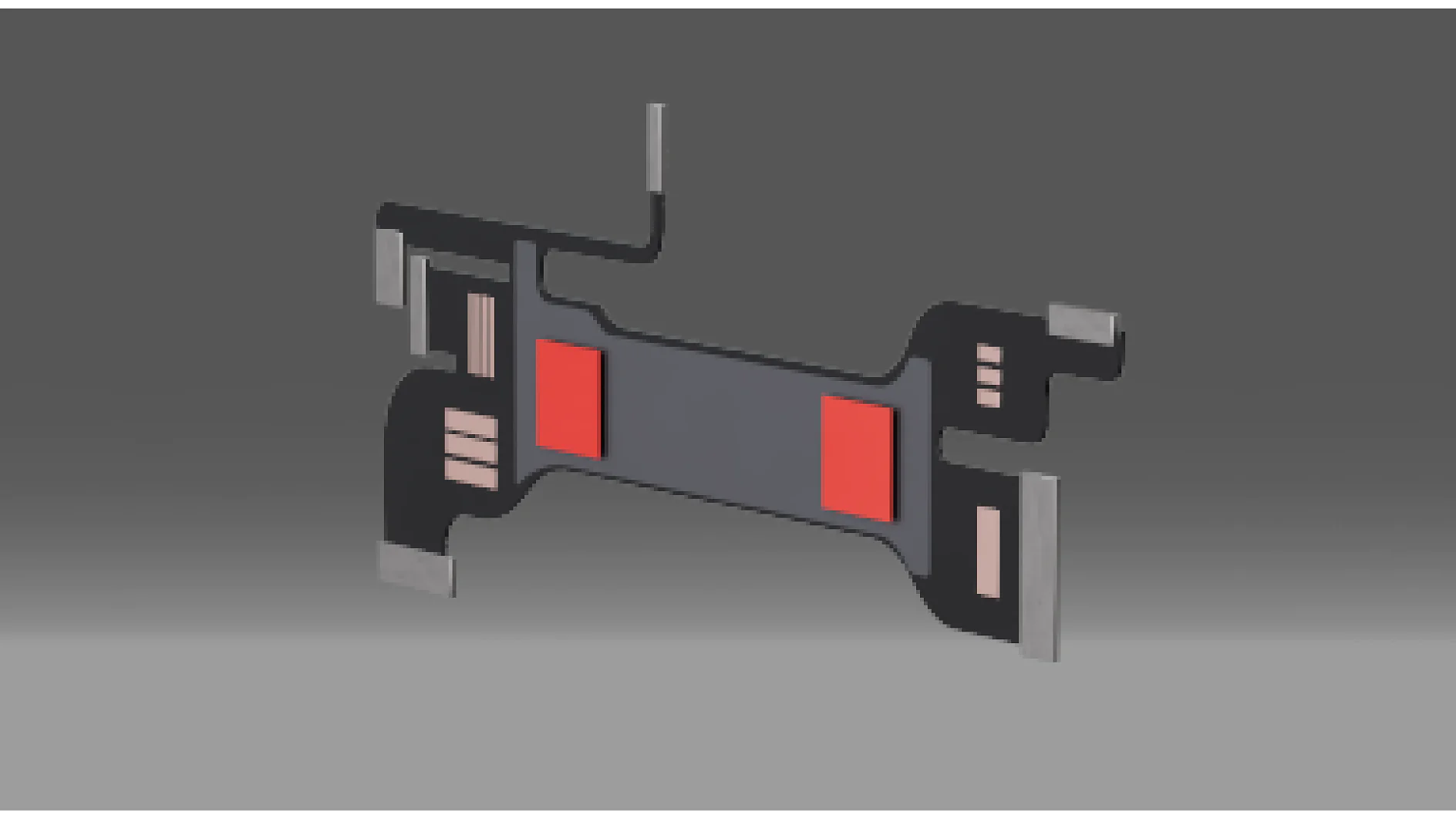

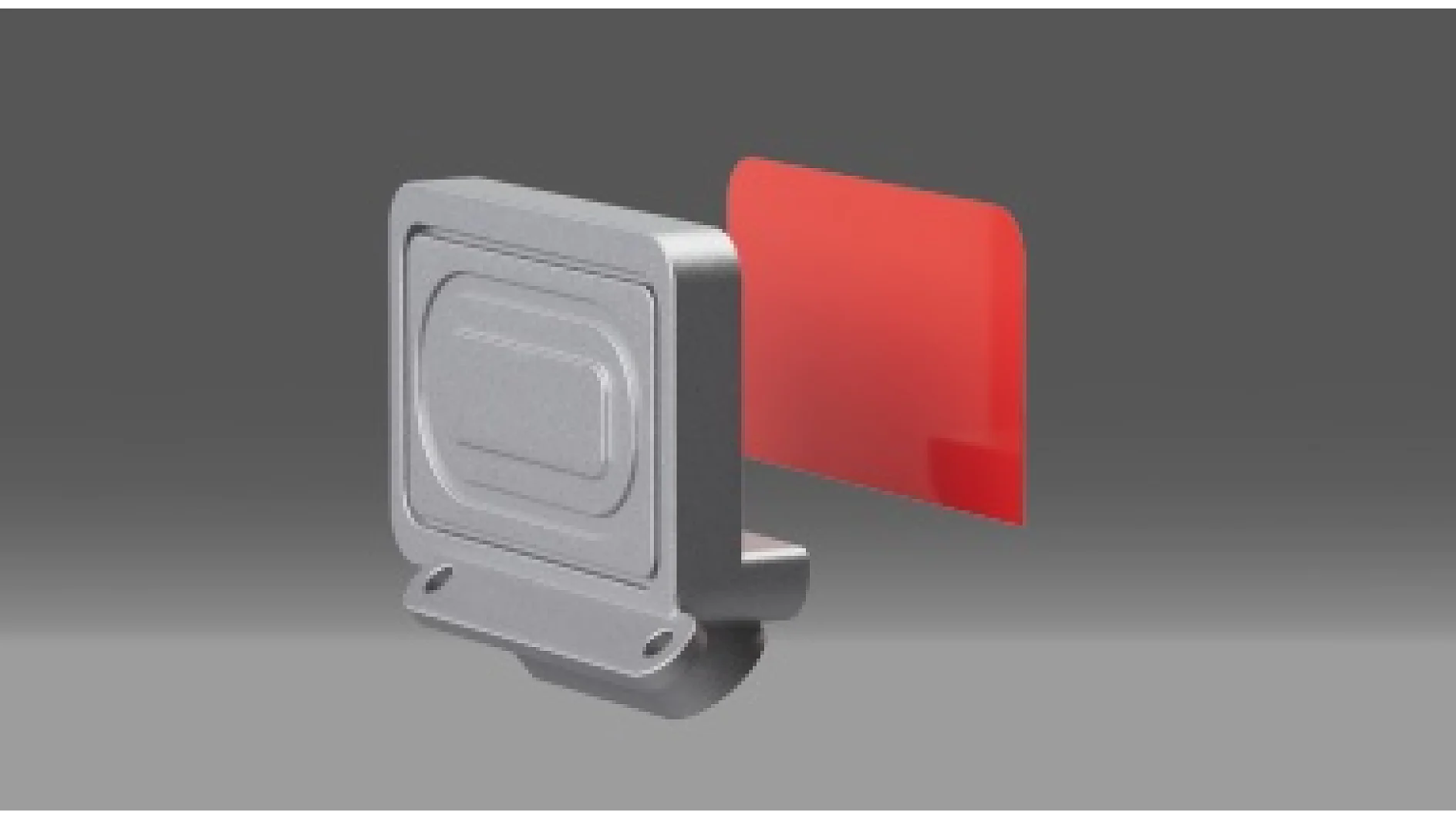

At tesa, we have made it our mission to develop innovative conductive adhesive tapes to safeguard electronic components. Our shielding tapes provide electrical equipment protection that meets electromagnetic compatibility (EMC) standards and can be used for additional applications, such as bonding, mounting, sealing, cushioning, and encapsulation. Our advanced electromagnetic shielding solutions deliver reliable performance and allow tapes to be applied precisely, even at high production speeds.

Find your ideal shielding tape

Our shielding tapes provide reliable electromagnetic shielding solutions to effectively minimize interference from external sources. Engineered from highly conductive copper and aluminum, our tapes create an electromagnetic shield around your device, thereby safeguarding its fragile components.

So, if you are looking for wireless device shielding or cable and wire shielding, you will find a suitable tape for your application with our product finder. With shielding tapes from tesa, you can be certain that your electronic devices operate without disruption, maintaining their performance and reliability, even in demanding environments.

Why you should be concerned about EMI / RFI

Electromagnetic interference (EMI) and radio frequency interference (RFI) pose significant challenges in designing and maintaining reliable electronic systems. Effective electromagnetic shielding solutions and robust design practices are essential to reduce the impact of EMI, whether it originates from natural sources, like lightning, or manufactured sources, such as electrical circuits, radio transmitters, or even other electronic devices.

Why is EMI / RFI a concern for electronics manufacturers?

EMI and RFI can severely affect the performance and reliability of devices. When exposed to electronic components, it can cause them to malfunction or operate unpredictably. For computing and data storage devices, this could lead to compromised, corrupted, or even lost data.

EMI / RFI can also cause interference in the transmission and reception of signals, causing data errors and communication disruptions in radios, televisions, and wireless networks. It can also cause noise and static interference in audio and video equipment, degrading the quality of sound and picture.

As you can see, addressing EMI and RFI is crucial for ensuring the optimal performance and longevity of electronic devices. By implementing robust shielding solutions and adhering to best design practices, you can protect your products while maintaining rigorous standards of quality and reliability.

Shielding tapes delivering solutions to protect your devices

Smartphones, tablets, displays, OLED technologies, notebooks, TVs and monitors, wearables, accessories, smart home devices – whatever you manufacture, our conductive adhesive tapes allow you to design modern, sleek devices that deliver maximum performance and high functionality.

Our assortment includes copper and aluminum foil shielding tapes, specifically designed to safeguard electronic components and devices from EMI and RFI. Our tapes play a crucial role in electrical equipment protection by effectively blocking external electromagnetic radiation.

Meeting stringent EMI requirements is crucial for product safety, as they ensure that electronic devices and systems can operate without causing or experiencing harmful interference from other electronic devices. However, they create design challenges for engineers, as high-frequency switching in power electronics systems creates the precise electrical conditions that are the main sources of EMI. By incorporating shielding tapes into your designs, you can effectively mitigate EMI, ensuring that electronic devices meet stringent safety and performance standards. Some shielding tapes also offer thermal management properties to dissipate heat generated by high-frequency switching components.

Frequently asked questions regarding shielding tapes

How do shielding tapes improve electronic device performance and reliability?

Shielding tapes play a crucial role in improving the performance and reliability of electronic devices by protecting them from electromagnetic interference (EMI). They form a conductive barrier around sensitive electronic components, blocking electromagnetic waves from entering or leaving the device. This minimizes the risk of interference that could disrupt normal functionality. Shielding tapes protect electronic components from EMI-induced damage, extending their lifespan, and reducing the likelihood of premature failure. Using shielding tapes helps ensure that electronic devices meet stringent regulations regarding electromagnetic compatibility (EMC).

What are the key factors to consider when selecting shielding tapes for specific applications?

On top of the usual considerations such as material compatibility, adhesive strength, and environmental resistance, you should consider several additional factors when selecting shielding tapes to provide specific electrical equipment protection. Firstly, you need to establish the tape's electrical conductivity, as this is crucial for effective electromagnetic interference (EMI) shielding. Then, check the tape's electromagnetic wave attenuation, typically measured in decibels (dB) across various frequencies. Next, you should ensure the tape meets industry standards and regulations for EMI shielding and electromagnetic compatibility (EMC). And finally, some applications require tapes that can manage heat effectively, so check the thermal conductivity of the tape if heat dissipation is a concern for you.