Parameter Influence on Bonding Strength of Pressure-Sensitive Adhesive (PSA) Tape:

Introduction

Pressure-Sensitive Adhesive (PSA) tapes are essential across a wide range of industries—including manufacturing, construction, automotive, electronics, medical devices, and consumer products. Their value lies in the ability to form durable and reliable bonds instantly, offering a fast and efficient alternative to traditional fastening methods.

Unlike liquid adhesives that require curing or drying, PSA tapes bond upon light pressure, streamlining assembly processes and reducing production time. However, achieving optimal bonding performance depends on a complex interplay of factors, including adhesive formulation, substrate material properties, application technique, and environmental conditions. However, achieving optimal performance is not simply a matter of applying tape.

The bonding strength of PSA tapes is shaped by multiple factors: the adhesive formulation, the characteristics of the substrate, application processes and environmental conditions.

This whitepaper explores these parameters in detail, providing engineers, designers, and manufacturers with a framework to understand, predict, and optimize PSA tape performance.

Unlike liquid adhesives that require curing or drying, PSA tapes bond immediately with light pressure, offering speed and simplicity. Yet the strength and durability of these bonds depend on a complex balance of chemistry, surface science, and application practice.

Understanding the interplay of these factors is essential to:

- Select the right PSA tape for a given application.

- Maximize performance under real-world conditions.

- Ensure durability and reliability throughout the product lifecycle.

Parameter Influence on Bonding Strength of Pressure-Sensitive Adhesive (PSA) Tape

tesa Customer Solution Center Thailand

Key Parameters Affecting Bonding Strength

Bond strength is influenced by three main categories of parameters:

1. Adhesive Formulation

- Chemical Composition: Acrylic, rubber, or silicone chemistry provide different performance profiles. Acrylics deliver ageing and UV resistance, rubber-based PSAs offer high initial tack, while silicones excel at high temperatures and low-energy surfaces.

- Tackifiers and Additives: Adjust adhesion, flexibility, and mechanical stability.

- Cohesive Strength: Determines the adhesive’s internal resistance to rupture — vital for high-load uses.

- Crosslinking: Enhances resistance to heat and creep but may reduce peel adhesion.

- Viscoelasticity: Balances deformation and recovery, directly influencing peel, tack, and shear performance.

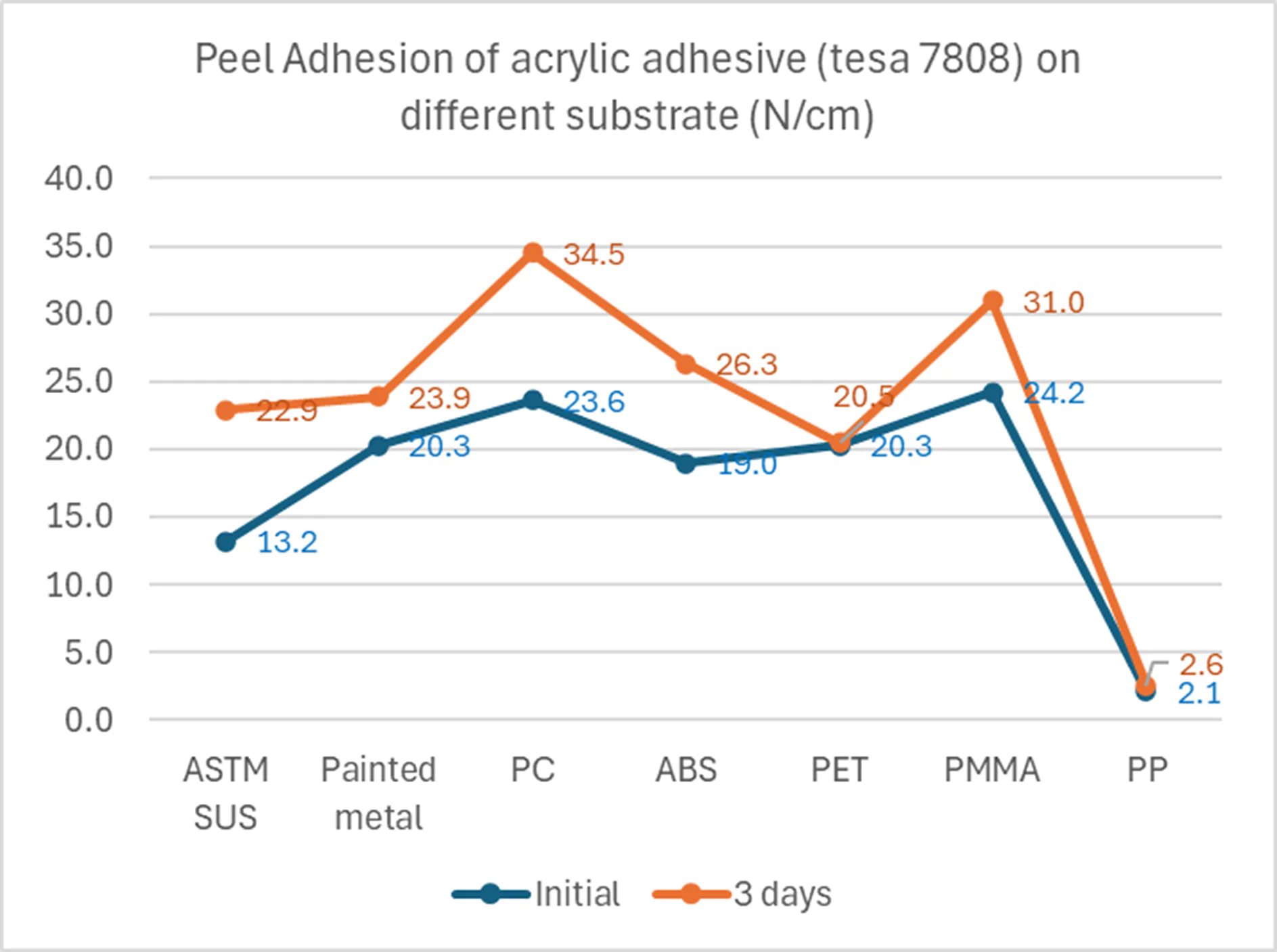

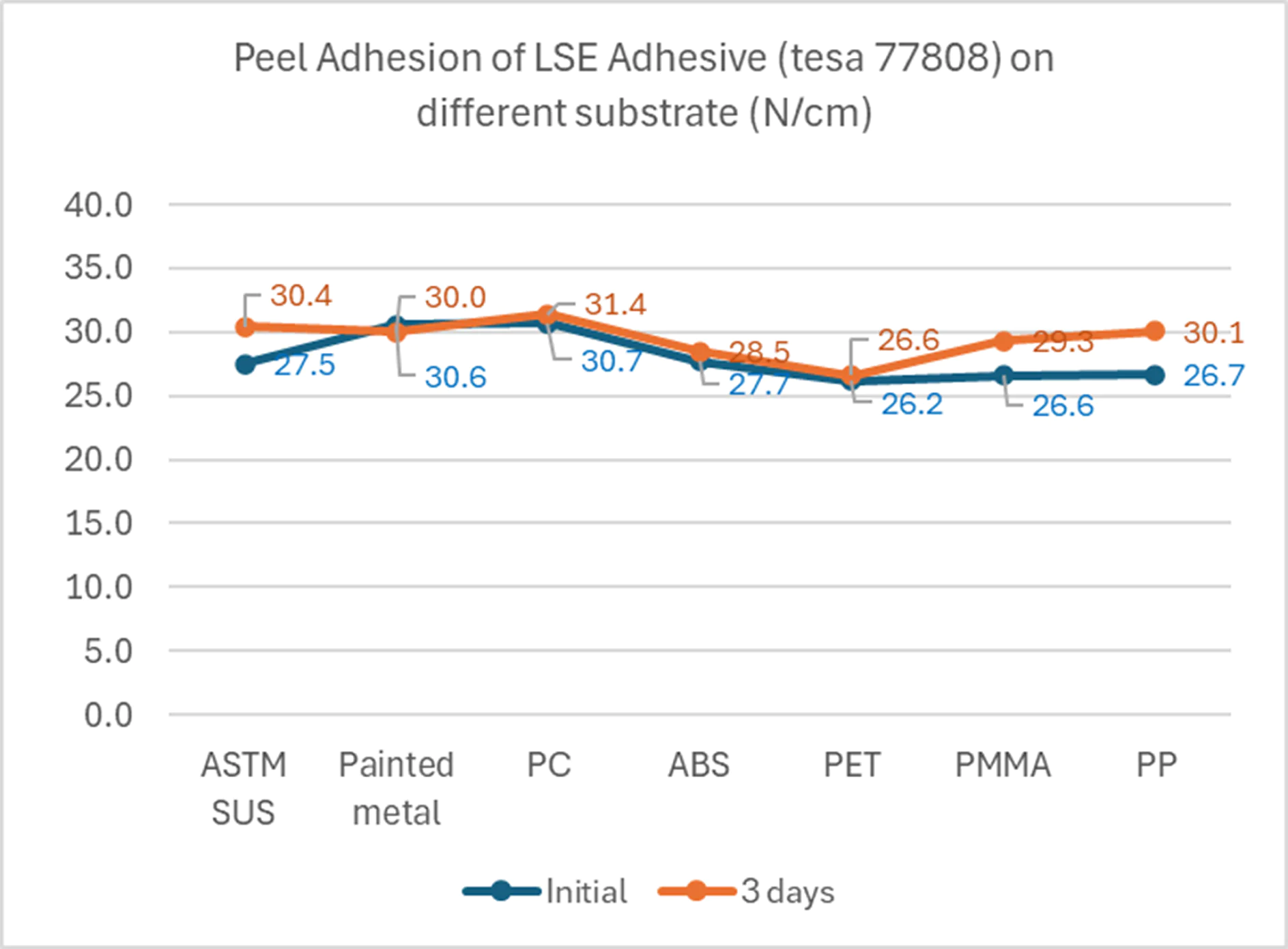

Experiment 1. Compare peel adhesion performance between 2 Adhesive types on different substrates.

a. Tape sample:

i. tesa ACXplus 7808

Acrylic adhesive.

Total thickness 0.8 mm

ii. tesa ACXplus 77808

LSE adhesive

Total thickness 0.8 mm

b. Substrate:

i. Low Surface Energy Substrate (LSE): Polypropylene (PP)

ii. High Surface Energy (HSE) and Medium Surface Energy (MSE) Substrate: ASTM Stainless steel (SUS), Painted metal, Polycarbonate (PC), ABS, Polyester (PET) and PMMA

c. Dwell time:

i. Immediately (with 5min) at room temperature

ii. After 3 days at room temperature.

d. Test result:

ACXplus 7808 exhibits varying adhesion levels depending on the substrate material. It performs well on HSE and MSE substrates, but shows limited bonding performance on LSE substrates (PP), as illustrated in Graph 1. In contrast, ACXplus 77808, which is formulated with an LSE adhesive, demonstrates excellent bonding performance on LSE substrates (PP), as shown in Graph 2.

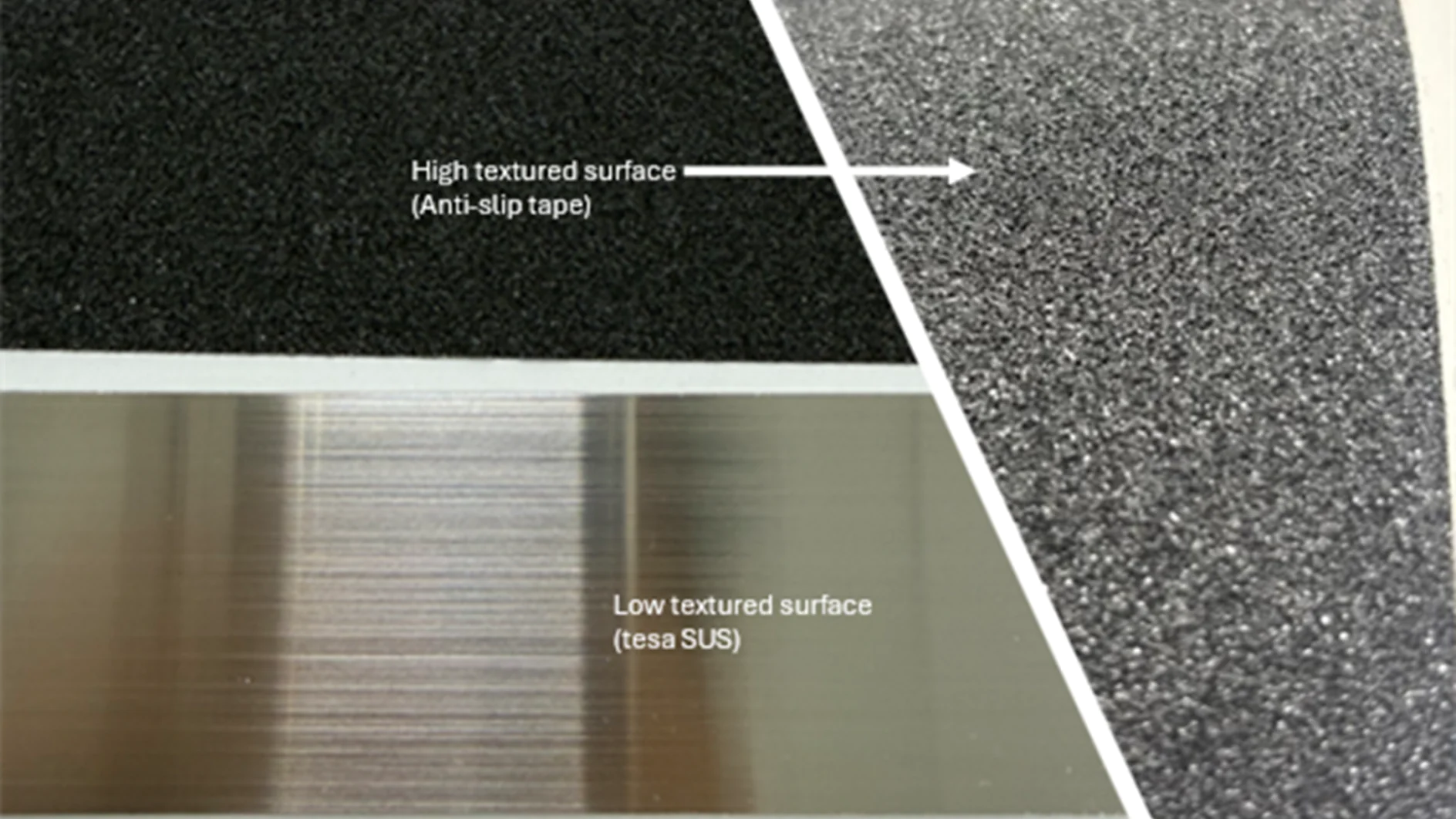

Picture 1: high textured and light texture surface

2. Substrate Characteristics

- Surface Energy: High-energy surfaces (e.g., metals, glass) enable strong adhesion. Low-energy plastics (e.g., PE, PP) may require specialized PSAs or primers.

- Surface Cleanliness: Dust, oil, and contaminants significantly reduce bond strength.

- Roughness: Light texture can improve bonding area, but excessive roughness can limit adhesive wetting.

- Material Compatibility: Chemical interactions between adhesive and substrate can affect long-term performance.

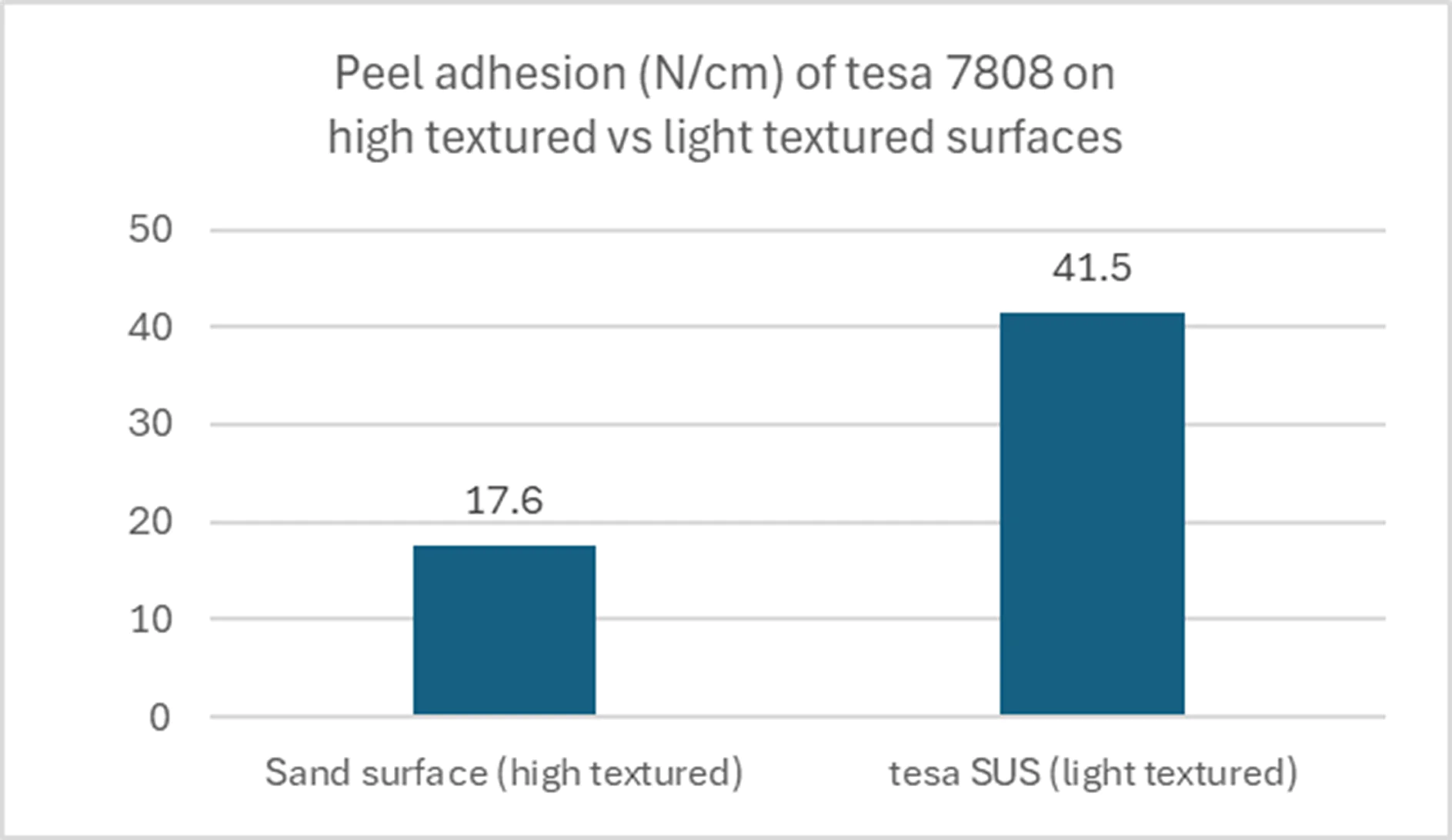

Experiment 2. Compare peel adhesion performance between different surface roughness.

a. Tape sample:

- tesa ACXplus 7808

- Acrylic adhesive

- Total thickness 0.8 mm

b. Substrate:

- High textured surface

anti-slip tape (sand surface)

- Light textured surface

tesa stainless steel (SUS)

c. Dwell time: Immediately test (within 5 minutes after applied pressure)

Graph 3: Peel Adhesion test result comparison between high textured and light textured surfaces

d. Test result:

Lightly textured surfaces, such as tesa SUS, enhance the effective bonding area, resulting in high bonding strength. In contrast, highly textured surfaces, like sandpaper, reduce the contact area between the adhesive and the substrate, leading to lower bonding strength.

3. Application & Environmental Conditions

- Application Pressure: Ensures intimate contact and proper wetting.

- Dwell Time: Allows the adhesive to flow into surface irregularities, strengthening the bond.

- Temperature: Affects tack, flow, and stability. Cold may cause brittleness, while heat can soften adhesives.

- Humidity & Moisture: Can weaken adhesion unless moisture-resistant PSAs or primers are used.

- Aging & Exposure: UV, ozone, and chemicals impact long-term reliability.

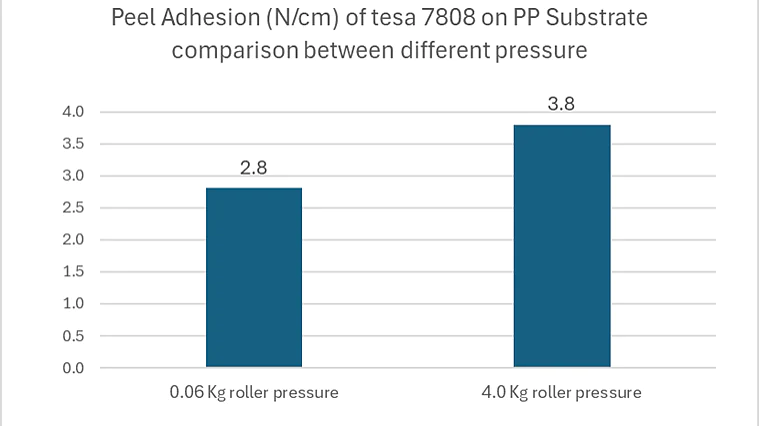

Experiment 3. Compare peel adhesion performance between 2 different pressures.

a. Tape sample:

- tesa ACXplus 7808

- Acrylic adhesive.

- Total thickness 0.8 mm

b. Substrate:

- Low Surface Energy Substrate: Polypropylene (PP)

c. Pressure:

- 0.06 Kg roller pressure, 4 back & forth

- 4.0 Kg roller pressure, 4 back & forth

d. Dwell time: Immediately after applied pressure (within 5min)

Graph 4: Peel Adhesion test result comparison between different substrates.

e. Test Result:

Applying higher pressure during tape application significantly enhances the adhesive's bonding strength. From this test, using a 4.0 kg roller pressure (4 back & forth) on ACXplus 7808 bonded to polypropylene (PP) resulted in markedly improved peel adhesion compared to the lower 0.06 kg pressure condition.

This effect is clearly illustrated in Graph 4, demonstrating the positive correlation between application pressure and adhesive performance within the first 5 minutes of dwell time.

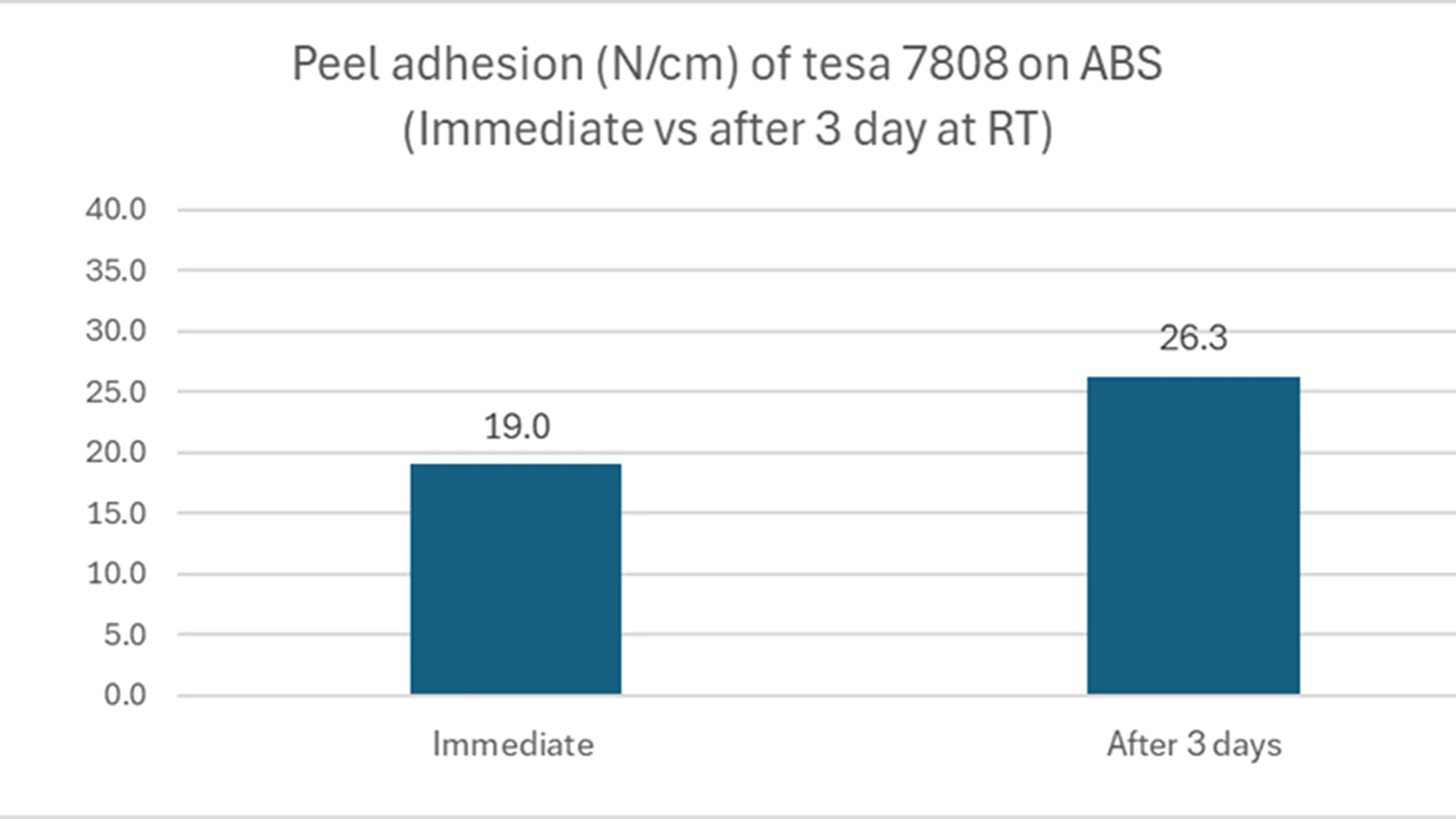

Experiment 4. Compare peel adhesion performance between immediate and after 3 days.

a. Tape sample:

- tesa ACXplus 7808

- Acrylic adhesive.

- Total thickness 0.8 mm

b. Substrate:

- Substrate: ABS

c. Pressure: 4Kg roller, 5 back & forth

d. Dwell time:

- Immediate (within 5min)

- After 3 days in room temperature.

Graph 5: Peel Adhesion test result of ACXpus 7808 on ABS comparison between immediate bonding and after 3 days

e. Test Result:

After a 3-day aging period at room temperature, the peel adhesion strength of tesa ACXplus 7808 on ABS increased significantly. Compared to the immediate adhesion measured within 5 minutes of application, the bond strength improved by approximately 38%, indicating that dwell time positively influences adhesive performance. This enhancement is clearly illustrated in Graph 5.

Case Studies

Automotive Trim Attachment

PSA tapes are widely used to secure exterior trims to painted metal. Success requires:

- Acrylic PSAs with high cohesive strength and UV resistance.

- Surface cleaning to remove oils and waxes.

- Correct temperature, pressure, and dwell time during application.

- Adhesion promoters or LSE adhesive for difficult finishes or LSE substrate.

Best Practices for Optimizing PSA Tape Bonding Strength

To ensure reliable and high-performance bonding with Pressure-Sensitive Adhesive (PSA) tapes, practitioners should follow these key best practices:

1. Select the Appropriate Adhesive Type

Match adhesive chemistry to substrate type and application demands.

2. Prepare the Substrate Surface

Clean surfaces thoroughly to remove dust, oils, and contaminants.

Evaluate surface energy and texture; lightly textured surfaces can improve bonding, while excessive roughness may reduce contact area.

3. Apply Adequate Pressure

Use sufficient application pressure to promote adhesive wetting and maximize contact area.

Higher pressure has been shown to significantly improve peel adhesion, especially on challenging substrates.

4. Allow for Proper Dwell Time

Adhesive strength increases over time; allow aging (e.g., 3 days at room temperature) to achieve optimal bond strength.

Immediate testing may underestimate long-term performance.

5. Consider Environmental Conditions

Apply tape within recommended temperature and humidity ranges.

Account for exposure to UV, chemicals, and mechanical stress over the product lifecycle.

6. Use Standardized Testing

Apply standardized testing methods such as peel adhesion, shear adhesion, and loop tack to ensure reliable evaluation of bonding performance under controlled conditions.

Conclusion

Pressure-Sensitive Adhesive (PSA) tapes offer outstanding convenience and versatility across industries. However, their performance is highly dependent on a combination of adhesive chemistry, substrate characteristics, application technique, and environmental conditions.

This whitepaper demonstrates that:

- Adhesive selection must be tailored to the substrate's material properties—such as surface energy and texture—as well as the specific performance requirements of the application, to ensure optimal compatibility and bonding effectiveness.

- Application pressure and dwell time are critical parameters that directly influence the adhesive’s ability to wet out and form strong, durable bonds

By understanding and controlling these parameters, engineers and designers can confidently select and apply PSA tapes to meet demanding performance requirements, ensuring product quality and customer satisfaction across diverse applications.