There is a good reason for why it is pressure-sensitive adhesive that makes adhesive tape sticky. Or actually there are multiple reasons that make pressure-sensitive adhesives and thus adhesive tape an ideal partner for many applications.

Why is it Pressure-sensitive Adhesives that Work in Tapes?

Technologies

Pressure-sensitive adhesives ensure that adhesive tape can bond at the slightest of touch. The combination of various properties makes it effective.

What Is Pressure-sensitive Adhesive?

To start with, pressure-sensitive adhesive is a kind of adhesive. More precisely: the adhesive that is found on adhesive tape. Pressure-sensitive adhesives have a special formulation: They combine viscosity - the state of being thick, sticky, and semifluid in consistency like honey for example - with elasticity - like rubber has for example. They adhere well on a surface (adhesion) and are equally solid and stiff in and of themselves (cohesion). In order to achieve that, the adhesive substance must consist of specific raw materials.

For example, natural rubber can be added since it has especially strong adhesion through the inclusion of resins. Adhesive tape on a natural rubber basis is applied, for instance, when we need to cover surfaces for painting work or seal up boxes. If adhesive tape must stick for a particularly long time, withstand UV sunlight and extreme temperatures, then pressure-sensitive adhesives made of acrylate are usually used. They can be adjusted even better to the specific requirements because acrylate consists of synthetic polymers that can be "tailored."

The Production of transparent adhesive tape (i.e. tesafilm®)

Let us stick with the example of natural rubber and look at the production of a single-sided tape to keep it simple. After the large ball of natural rubber raw material has been reduced to small pieces, it is mixed with resin and other materials, dissolved and homogenized. The additional materials are selected according to the specific requirements for adhesives, in order to achieve high resistance to aging, for example. A water-based technology patented for tesa makes this process mostly environmentally friendly without adding solvents.

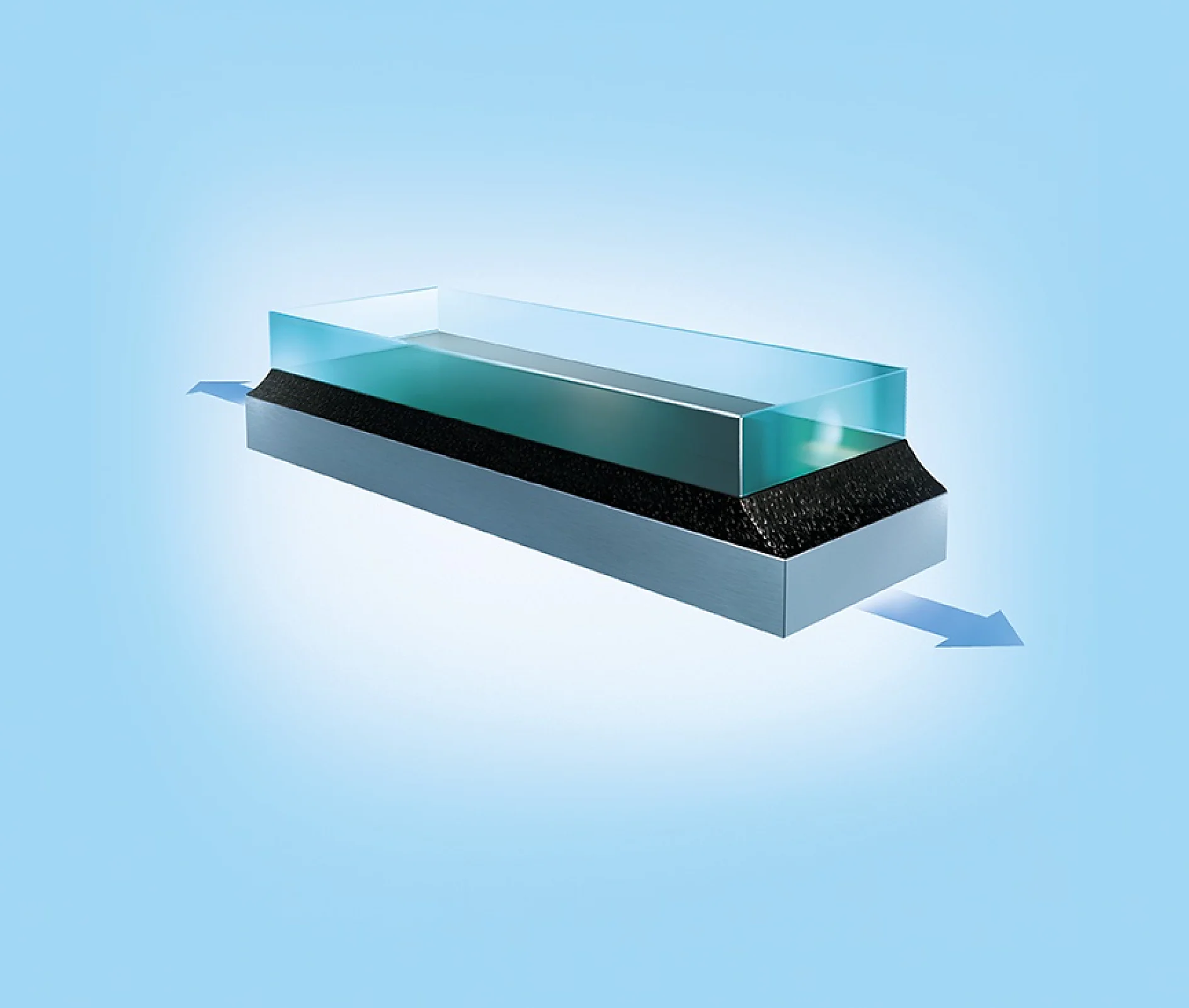

After the production of the adhesive, in special a production facility adhesive and backing are combined into one unit. The process works as follows:

In 8 steps to the final product:

- Pre-treatment: If necessary a pre- or corona treatment improves the pre-coat`s hold on the new backing material, which is made of polypropylene and measures 5,000 m in length and 1.33 m in width,

- Pre-coat: In the pre-coating process, a primer is applied to the backing. This gives the adhesive a better hold later on. Then a scraper removes the excess pre-coat,

- Drying: The pre-coat is followed by a brief drying process: The backing passes through five temperature zones, here the water in the pre-coat evaporates,

- Roller station: This stage evens out warping so that the film stays smooth under tension and does not wrinkle,

- Web edge control: The web is realigned with precision accuracy – this keeps it running straight on track the rest of the way without slipping off to the left or right

- Post-coat: The adhesive is applied using a pan roller and a deflection roller that can be lowered. At this stage as well, a scraper removes excess adhesive afterward.

- Drying: The pos-coat is followed by a final drying process. The backing covered with adhesive, which is still watery, passes through 12 drying zones. The temperatures rise steadily at first and then drop back down toward the end.

- Rolling: Finally the finished adhesive tape is winded onto large rolls and converted. That means, in a final working step it is cut into various sizes (length and width), wound onto the appropriately standardized roll cores and packaged.

Why Does Adhesive Tape Bond?

Why exactly is pressure-sensitive adhesive included in the adhesive tape? There are primarily two reasons for this. What is pressure-sensitive adhesive above all?

- Permanently tacky / gluey.

- It has so much stickiness (we call this "tack") that the low pressure is sufficient in order to bond the adhesive tape to a surface.

While in the case of liquid adhesives we cover the surface and must wait until the glue becomes hard, the pressure-sensitive adhesive solidifies the moment we press it with our pinkie. Pressure-sensitive adhesives provides everything that you value in a good colleague at work: they are permanently ready for work. And they do their job reliably and highly effectively.