01tesa® 74515

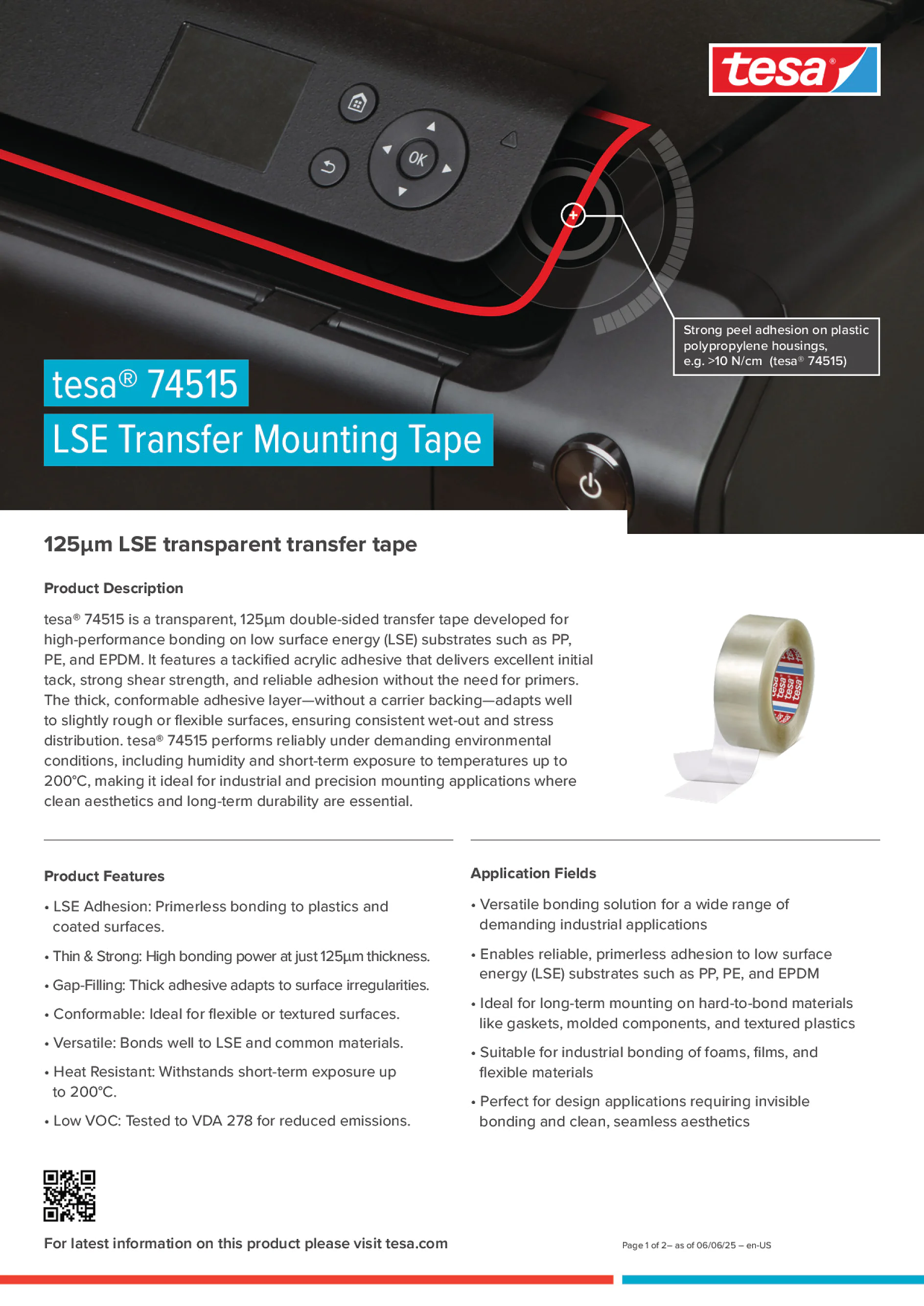

tesa® 74515 is highly conformable and features a tackified acrylic adhesive tailored for hard-to-bond substrates. It offers excellent peel adhesion, strong initial tack, and high shear strength. Its conformability enables seamless application of various die-cut shapes and sizes, making it ideal for complex and demanding geometries.