Partnering for the mobility of the future

Technologies

Triple expertise: tesa, Vulkan Technic, and Liebherr are elevating battery pack assembly for electric vehicles to a new level

Battery packs represent the heart of every vehicle that is powered electrically. Previously, many individual companies/contacts were necessary for bonding and assembling these battery systems. Now, with an adhesive tape producer, a material manufacturer, and a general contractor working closely together, customers can get everything from a single source. Battery production is thus simplified by implementing an automated and tape-based solution.

The collaboration combines the products, competencies as well as processes of the partners into an ideal solution:

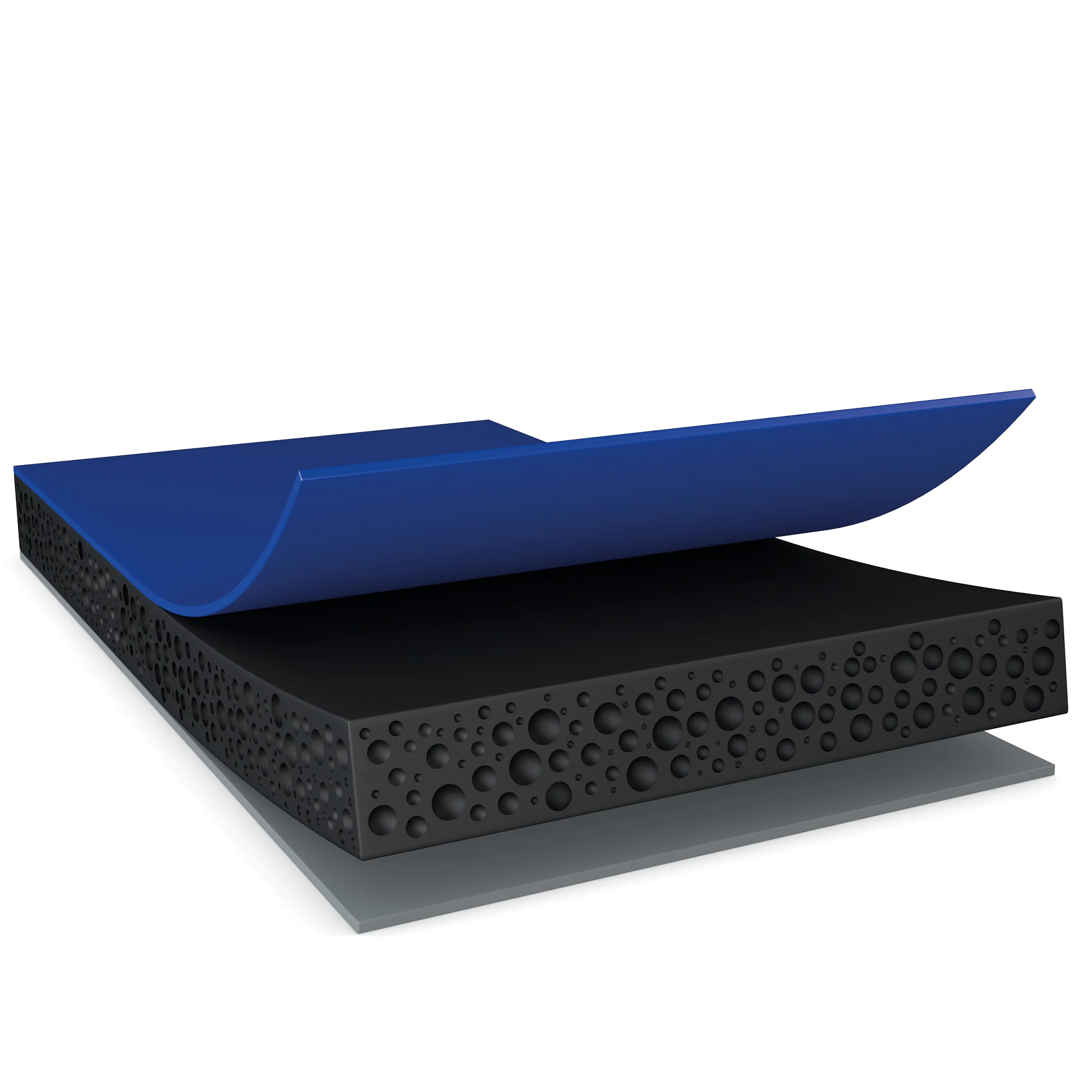

- With tesa® ACX 76730 Box Seal, tesa adds a new, flexible adhesive application that, in addition to the reliable, clean, and automated sealing of battery packs, also enables rework repair of the battery pack possible without any problems.

- Vulkan Technic delivers the appropriate application concept.

- Liebherr is responsible to implement the entire production process, as a general contractor.

A unique cooperation between specialist companies

Box seal application on battery pack

tesa® ACX 76730 Box Seal

- Can be attached to battery packs with lids and to battery packs that are directly mounted to the underbody

- 100% sealing with different gap dimensions

- Does not require any curing time and can be applied easily and automatically

- Health and safety risks for users are minimized

- Battery pack can be reopened during production or after end-of-line testing for reworking

- 100% sealing with different gap dimensions

- Does not require any curing time and can be applied easily and automatically

- Health and safety risks for users are minimized

- Battery pack can be reopened during production or after end-of-line testing for reworking