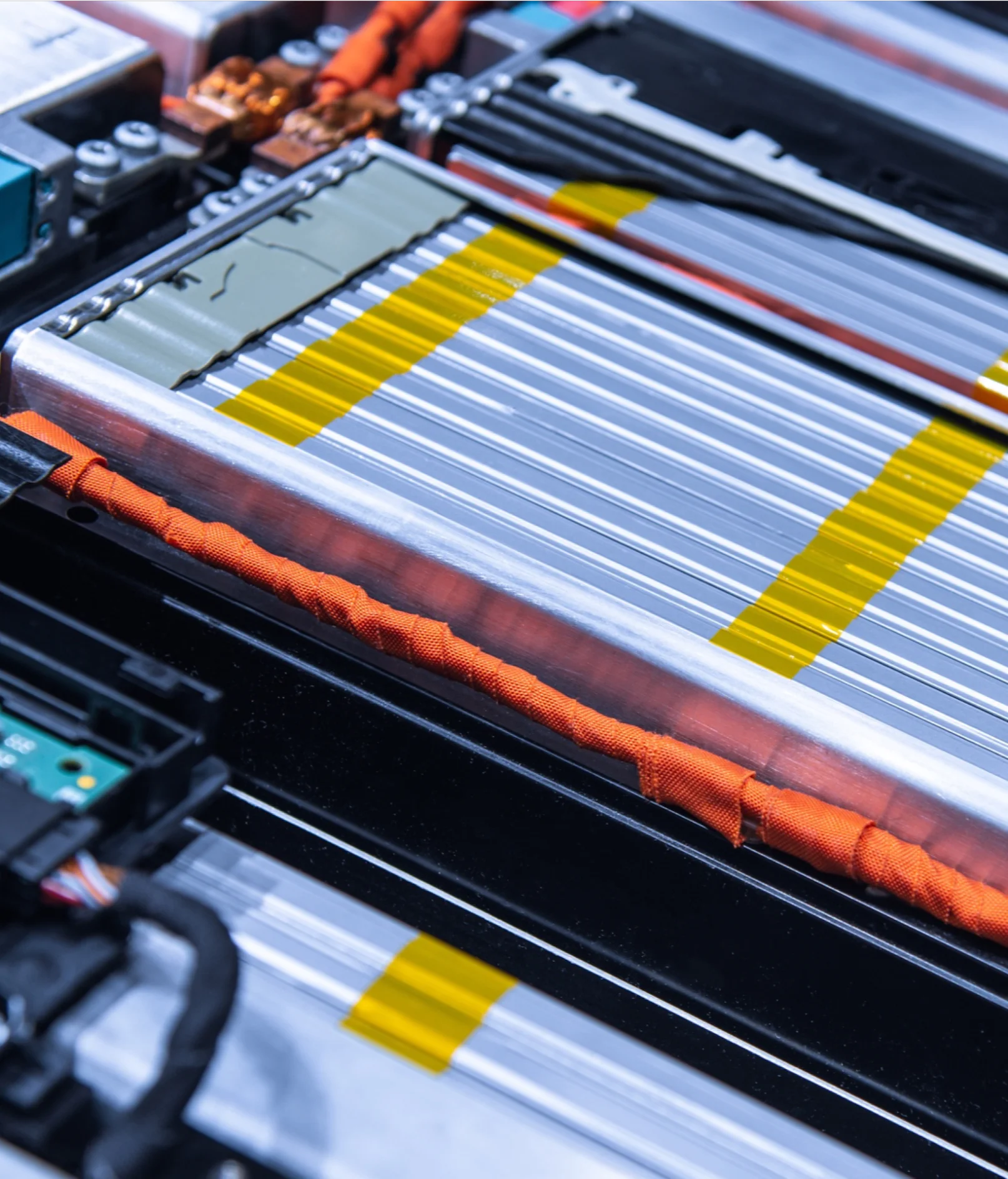

Wire harnessing tapes helps manufacturers to form, route and protect cables to facilitate production of electrical distribution systems and vehicle assembly as well as ensuring functionality in all conditions reducing the risk of short circuits or malfunctions.

Nowadays, cars are not only examples of high-quality mechanical engineering but also true high-performance computers. Thanks to their complex sensor and control systems, vehicles may need up to 8 km of cable and wires for data and power transmission. This is why we offer wire harness tapes and sleeves covering all vital automotive applications – from providing protection against noise and abrasion to resisting temperature and environmental conditions.

The automotive sector is always innovating. So, our experts work closely with wire harness manufacturers and OEMs to ensure they meet the demands of the major players. For example, we’re developing 2D and 3D shaping solutions using our wire harness tapes to optimize space, minimize routing, and save up to 80% weight compared to non-tape solutions.