Elektronik-Klebelösungen: Die Zukunft der Unterhaltungselektronik

Da die Innovationen in der Elektronikindustrie weiterhin in rasantem Tempo zunehmen, stellt die Produktion elektronischer Bauteile die Hersteller vor noch größere Herausforderungen. Anwendungen und Geräte erfordern oft einzigartige Klebelösungen, wobei die Teile immer kleiner und komplexer werden, während die Produktqualität und -leistung erhalten bleiben muss.

Wir bei tesa® haben es uns zur Aufgabe gemacht, hochmoderne Klebebänder für Elektronikkomponenten zu entwickeln, die vielfältige Anwendungen wie Kleben, Montieren, Abdichten, Polstern, Abschirmen und Verkapseln ermöglichen. Unsere fortschrittlichen Klebelösungen für die Elektronik ermöglichen eine präzise Anwendung bei hohen Produktionsraten und eine zuverlässige Leistung.

Wählen Sie aus einer breiten Palette speziell entwickelter Elektronik-Klebebänder für eine Vielzahl von Geräten, die Ihre spezifischen Anforderungen erfüllen. Wir haben uns in den letzten 30 Jahren erfolgreich mit der Elektronikindustrie weiterentwickelt und unsere Nähe zu unseren Kunden ermöglicht es uns, zukünftige Trends im Produktdesign zu antizipieren. Als weltweit führender Anbieter von Klebelösungen für die Elektronikindustrie kann tesa® mit Stolz sagen: Wir gestalten das Feld der Elektroniktechnologien von heute und ermöglichen die Entwicklungen von morgen.

Geräte und typische Anwendungen von Klebebändern für die Elektronikindustrie

Mit unserem hochentwickelten technologischen Fachwissen in der Anwendung von Klebebändern in elektronischen Geräten können wir Ihnen helfen, das Klebeband auszuwählen, das Ihren Anforderungen am besten entspricht. Wir entwickeln gemeinsam mit führenden OEMs und Komponentenherstellern der Branche. Werfen Sie einen Blick auf unsere innovativen Klebebandlösungen, optimieren Sie die Produktionsprozesse Ihrer Geräte und profitieren Sie von mehr Designfreiheit:

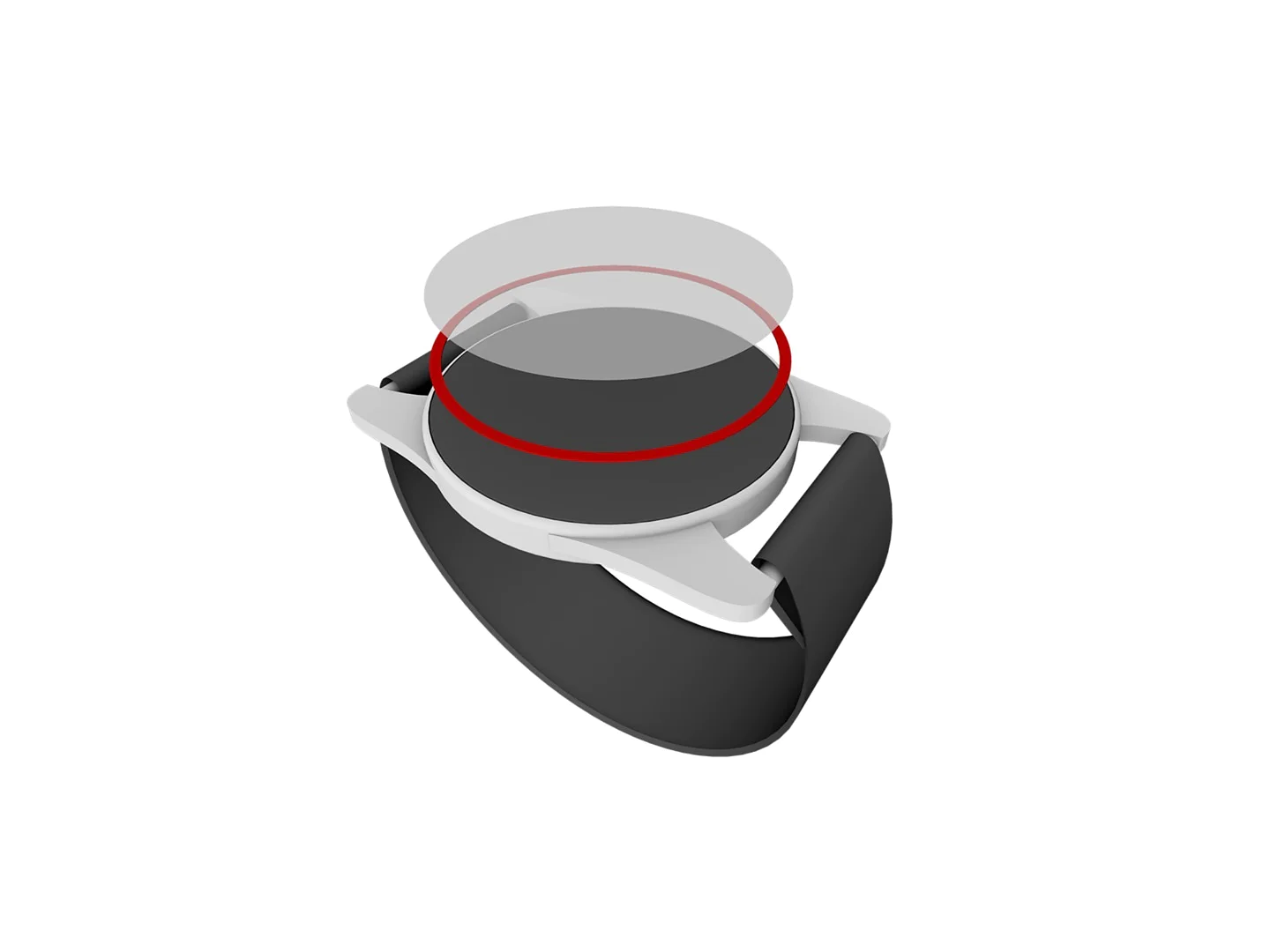

Smartphones, Tablets, Displays, OLED-Technologien, Notebooks, Fernseher und Monitore, Wearables, Zubehör, Smart Home.

Unsere breite Palette an Klebebändern für elektronische Anwendungen bietet Ihren Geräten maximale Leistung, modernes Design und hohe Funktionalität.

Elektronikklebebänder für Gerätekomponenten

Haupteigenschaften unserer Klebebänder für die Elektronikindustrie

Wir kennen die Schlüsselfaktoren, die für ein Klebeband erforderlich sind, um Ihnen die ideale Leistung zu bieten.

Ob Sie doppelseitiges Klebeband oder leitfähiges Klebeband für die Elektronik benötigen: Wir haben da Richtige für Sie. Unsere Produkte gewährleisten beste Verklebung, Schutz und Langlebigkeit sowie die Fähigkeit, selbst den härtesten Umweltbedingungen wie Schwingungen, Feuchtigkeit und Temperaturschwankungen standzuhalten. Gleichzeitig tragen wir mit unseren Produkten aktiv zur Nachhaltigkeit bei. Indem wir es ermöglichen, die einzelnen Komponenten eines Smartphones leicht zu entfernen, verbessern wir seine Wiederverwertbarkeit und zielen darauf ab, die Lebensdauer Ihrer elektronischen Geräte im Allgemeinen zu verlängern. Bei den Materialien unserer Klebebänder für die Elektronikindustrie ist uns die Verwendung von umwelt- und klimafreundlicheren, recycelten und organischen Rohstoffen bei gleichbleibender Qualität ein wichtiges Anliegen.

Die wichtigsten Klebebänder in unserer Produktpalette lassen sich in die Kategorien Montagelösungen, Funktionslösungen und Display-Laminierungslösungen einteilen. Jedes Klebebandsortiment kombiniert verschiedene Eigenschaften, die für die Erfüllung spezifischer Funktionen für Ihre elektronischen Anwendungen benötigt werden. Zu diesen Eigenschaften gehören unter anderem:

- Klebeleistung

- Stoßfestigkeit

- Rückstandsfreies Ablösen

- Repulsionsbeständigkeit

- LSE-Leistung

- Verlässlichkeit

- Chemische Beständigkeit

- Anpassungsfähigkeit

- Elektrische Leitfähigkeit

- Thermomanagement

- Feuchtigkeitssperrung

- Widerstandsfähig gegen Ausgasungen

Klebebänder für die Elektronikindustrie: Unsere Produktpalette

Da die Materialien und Eigenschaften von Elektronikklebebändern variieren, lässt sich nur schwer herausfinden, welches Klebeband für Ihre spezifische Elektronik geeignet ist.

Mit unseren zuverlässigen Lösungen und unserem außergewöhnlichen Service unterstützen wir Sie während des gesamten Produktentwicklungsprozesses, um die beste Klebebandlösung für Ihre individuellen Anforderungen zu finden. Unsere globalen Key-Account-Management-Teams bieten länderübergreifend und rund um die Uhr hervorragende Unterstützung. Darüber hinaus unterstützen unsere technischen Experten Sie direkt an Ihrem Produktionsstandort.